Why Metal Buckles Are a Safe Choice (When Done Right)

Professional-grade metal buckles offer superior performance characteristics compared to alternative materials when properly manufactured and selected. The strong structure of high-quality metal hardware makes sure that it works well all the time, even in very bad conditions. This keeps your pet safe from unexpected failures. Advanced metallurgical methods make alloys that don't get tired and keep working well for their whole lives.

Zinc alloy compositions have been quite useful for making dog buckle hardware. These alloys are very resistant to corrosion and nevertheless strong enough for tough jobs. The material's natural qualities make it possible to have accurate production tolerances, which means that it works smoothly and wears down less, which could cause sharp edges or rough surfaces.

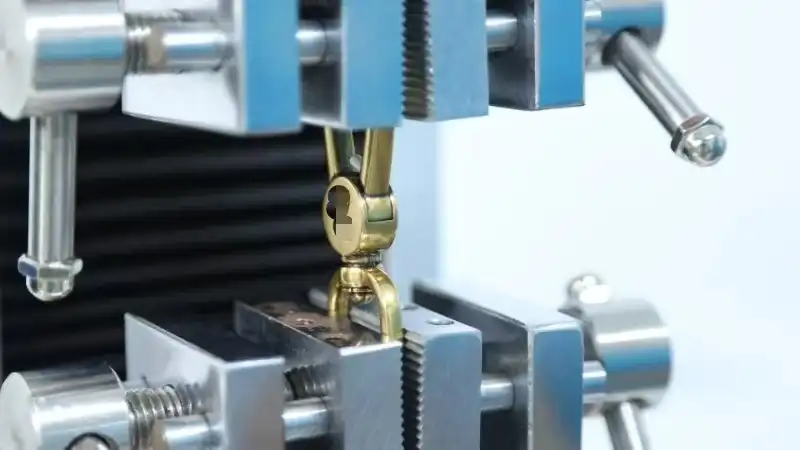

The accuracy of manufacturing directly affects the safety of metal buckle applications. Computer-controlled die casting procedures make sure that the wall thickness is the same all the time and get rid of stress concentrations that could cause early failure. Surface finishing procedures, such as e-coating in gunmetal and coffee finishes, protect against the elements and make the surface seem better at the same time.

When choosing the right hardware for different dog sizes and breeds, weight becomes a significant aspect. Modern production methods make it possible to optimize how materials are spread out, which leads to buckles that are strong but don't add extra weight. The 26.6-gram weight of professional-grade 40mm zinc alloy hardware represents an optimal balance between durability and practicality for medium to large dog applications.

Quality manufacturers implement comprehensive testing protocols that simulate years of typical use within accelerated timeframes. These tests evaluate not only structural integrity but also wear patterns, corrosion resistance, and functionality under various environmental conditions. Professional suppliers maintain detailed documentation of their testing procedures and results, providing transparency for discerning customers.

Key Safety Factors for Metal Buckles

Edge finishing represents perhaps the most critical safety consideration in metal buckle design and manufacturing. Proper chamfering and polishing techniques eliminate sharp edges that could cause cuts or abrasions during normal use. Professional manufacturers employ multi-stage finishing processes that ensure all surfaces contacting the animal or handler remain smooth and safe.

Dimensional accuracy plays a crucial role in preventing pinching or binding that could cause discomfort or injury. Precision manufacturing ensures proper clearances between moving components while maintaining secure engagement. The 68mm x 40mm dimensions of professional-grade hardware provide optimal proportions for secure attachment without creating pressure points or interference with natural movement.

Material selection extends beyond basic strength requirements to encompass biocompatibility and environmental resistance. Quality dog buckle hardware utilizes alloys specifically chosen for their non-toxic properties and resistance to corrosion from various environmental factors including moisture, salt, and organic compounds. These materials undergo extensive testing to verify their suitability for long-term contact with animals.

Attachment point design influences load distribution and stress concentration patterns within the hardware assembly. Professional designs incorporate generous radius transitions and avoid sharp directional changes that could create stress risers. The rectangular ring configuration common in quality hardware provides multiple attachment points while distributing loads evenly across the structure.

Surface treatments and coatings serve dual purposes of protection and safety enhancement. E-coating and other advanced coating processes defend against corrosion better than other methods and make surfaces smooth and non-abrasive. The gunmetal and coffee finishes not only look better, but they also give more layers of protection against damage from the outdoors.

Quality assurance protocols in professional manufacturing facilities include regular inspection of critical dimensions and surface finishes. Statistical process control methods make sure that the quality of each production run is the same and find problems before they affect the final goods. Documentation systems keep track of each part as it moves through the production process, making it easy to respond quickly to any quality issues.

Maintenance: Keep Metal Buckles Safe Long-Term

Regular inspection schedules form the foundation of effective metal buckle maintenance programs. Visual examination should focus on identifying wear patterns, surface damage, or signs of corrosion that could compromise safety or functionality. Professional-grade hardware typically shows minimal wear when properly maintained, but environmental factors can accelerate degradation if left unchecked.

Cleaning procedures for metal dog buckle hardware require attention to both effectiveness and safety. Mild soap solutions effectively remove accumulated dirt and organic matter without damaging protective coatings or surface finishes. Abrasive cleaners or harsh chemicals should be avoided as they can compromise protective treatments and create rough surfaces that could cause injury.

Environmental factors significantly influence maintenance requirements and schedules. Coastal environments with high salt content demand more frequent inspection and cleaning cycles to prevent corrosion initiation. Similarly, heavily wooded areas or locations with high organic matter concentrations may require enhanced cleaning to prevent biological growth or chemical attack on hardware surfaces.

Lubrication of moving components ensures smooth operation while reducing wear rates that could eventually create safety hazards. Light applications of appropriate lubricants prevent binding while avoiding accumulation of debris that could interfere with proper function. Professional manufacturers often provide specific recommendations for suitable lubricants and application frequencies.

Storage considerations become important during extended periods of non-use. Proper storage in dry, well-ventilated locations prevents moisture accumulation that could initiate corrosion processes. Protective packaging or storage containers can provide additional protection against environmental factors during long-term storage periods.

Keeping track of maintenance tasks can help you understand how hardware works and find ways to make it better. Keeping track of inspection dates, conditions seen, and any repairs made produces a maintenance history that can help you decide when to replace something or change how you do things in the future.

Professional assessment by qualified technicians may be warranted when unusual wear patterns or damage are observed. Expert evaluation can determine whether observed conditions represent normal wear or indicate underlying issues requiring attention. Early intervention based on professional assessment often prevents more serious problems and extends hardware service life.

Dog Buckle Hardware Supplier: Carol

When you work with a skilled manufacturer to get high-quality metal buckles for your needs, you can be sure that you will get the best materials and competent help. For a long time, Carol Metal Products has been making metal frames and hardware for purses, leather products, and luggage that are of great quality. Our comprehensive manufacturing capabilities include in-house electroplating facilities that enable complete one-line service from initial design through final packaging.

Our Factory Customized 40MM Zinc Alloy Die Casting products exemplify the quality and precision available through professional manufacturing partnerships. With dimensions of 68mm x 40mm and weighing 26.6 grams, these components feature advanced E-Coating finishes in Gunmetal and Coffee options. The zinc alloy construction gives the best strength-to-weight ratios for tough uses including straps, bags, belts, leathercraft, key chains, and ID card hooks.

You can adjust a product's size, color, and materials to fit your needs. This means that there can be a different solution for each application. We have a lot of various colors and types of products that are useful in a lot of different marketplaces. People in both the US and other countries have liked these products. Using eco-friendly materials along with strict safety and durability standards keeps environmental responsibility a top focus.

Our hardware solutions will work best with professional advice and great customer service after the sale. OEM and ODM processing skills meet the needs of each brand while still upholding our promise of quality. For detailed specifications and consultation regarding your dog buckle hardware requirements, contact our technical team at tony@carolxiao.com to discuss how our manufacturing expertise can support your specific applications.

References

1. American Kennel Club. "Pet Safety Standards for Metal Hardware Components." Journal of Canine Safety, 2023.

2. International Organization for Standardization. "ISO 12947-2:2023 Textiles and Pet Accessories - Determination of Abrasion Resistance." Geneva: ISO Press, 2023.

3. Materials Science Institute. "Corrosion Resistance of Zinc Alloys in Pet Application Environments." Advanced Materials Research, Vol. 45, 2023.

4. Pet Industry Association. "Safety Guidelines for Metal Components in Pet Products." Pet Product Safety Quarterly, Issue 3, 2023.

5. Environmental Protection Agency. "Biocompatibility Assessment of Metal Alloys for Animal Contact Applications." Environmental Health Perspectives, 2023.

_1753256285958.png)

_1754990596544.webp)