Bag Buckles-Hardware Classification, Materials And Testing

In the design and purchase of bags, people often focus on the texture of the fabric, the beauty of the version, or the size of the capacity, but often ignore a key component that connects the function of the bag - the buckles-hardware. As the "connection hub" and "safety barrier" of the bag, the buckle seems small, but it directly determines the durability, safety, and user experience of the bag. From the fixation of the shoulder strap to the protection of the box, from the adjustment of the webbing to the comfort of carrying, the buckle is like an "invisible skeleton", supporting the use of the bag in all scenarios.

Function of the Buckle

In the functional system of the bag, the buckles-hardware is not a single component, but covers 8 series of "functional networks". Among them, 6 categories are high-frequency use models of daily bags, including buckles (also known as side buckles), hooks, and rope buckles that are responsible for fixing and load-bearing, rubber feet at the bottom of the box, shoulder pads that improve carrying comfort, and hardware buckles that take into account both texture and practicality; The other two categories are the pull rod that performs the mobile function and the tag that plays the role of identification, which work together to ensure the convenience and longevity of the bag from the details.

Buckle Disassembly: From "Safety Lock" to "Pressure Cushion": Their Specialized Division of Labor

As the "safety lock" of luggage, buckles are the core components that secure the shoulders and waist. They are typically made of POM (polyoxymethylene, commonly known as "Sygan"), PA (nylon), or PC (polycarbonate), materials that combine high toughness and impact resistance.

Buckles consist of a male and female buckle. The length can be adjusted as needed by sewing webbing at both ends. Advanced designs are now available, including invisible female buckles that can be replaced without removing stitches, and "Y-shaped three-way buckles" designed specifically for safety applications like strollers. Female buckles can also be customized with color labels and logos, or enhanced with electroplating, silk-screen printing, or painting.

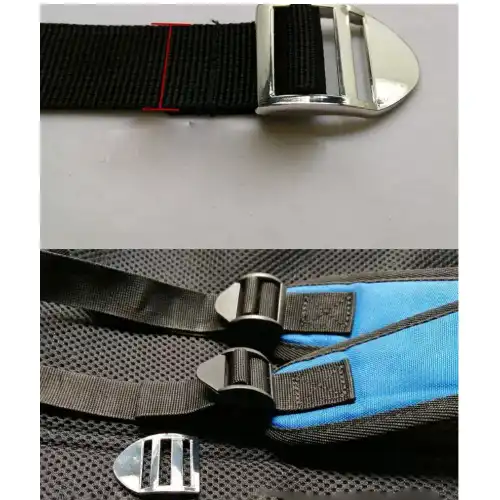

Hook buckles act more like webbing "adjusters." Made primarily of POM, PA, or PP (polypropylene), they are lightweight and wear-resistant. They're typically used in conjunction with D-buckles. Day buckles adjust the length of the webbing, while ladder buckles (a subtype of hook buckles) attach to the end of the webbing. They support electroplating and silk-screen printing, and can be designed with a logo. They're commonly found in backpack shoulder straps and waist belt adjustments, ensuring the webbing's tightness is optimal for different uses.

The shoulder pad is mostly made of PVC, PU (polyurethane), TRP (thermoplastic rubber) or TPE (thermoplastic elastomer), which is soft and rebounds well, and the front (back) fits the shoulders and neck to reduce the feeling of pressure, and the back (abdomen) fixes the webbing to prevent slipping, and can also be arbitrarily colored and customized according to design needs, which is the key to improving the comfort of long-term carrying.

Hardware buckles are the "texture responsibility" of the bag, with POM as the basic material (the industry routine also includes zinc alloy, copper, etc.), covering hooks, day buckles, square buckles, keychains, chains, zipper pulls and other forms, the surface can be electroplated, which not only improves rust resistance but also increases gloss, which can not only meet practical needs, but also add a sense of sophistication to the bag.

Quality Judgment Criteria: 2 Major Tests to Screen Durable Buckles-Hardware

The core of judging the quality of buckles-hardwares lies in two key tests: the tensile test and the temperature test. The tensile test mainly tests the load-bearing capacity of the fastener, which is divided into an instantaneous tensile test and a persistent tensile test. Instantaneous tensile test simulates sudden external forces (such as backpack dropping, pulling) for load-bearing parts such as buckles, D-buckles, and daily buckles, to detect whether they are broken or disconnected to ensure safety in extreme scenarios. The long-lasting tensile test applies a fixed load to the fastener to record its continuous resistance and avoid failure due to material fatigue over time.

The temperature test focuses on the environmental adaptability of the fastener, and the high-temperature test requires placing the fastener in an environment of 70°C for 24 hours to observe whether it is deformed, softened, or cracked to cope with high temperature scenarios such as summer exposure. The low-temperature test is placed in an environment of -30°C for 24 hours to check whether it is brittle and tough to ensure normal use in a low-temperature environment in winter.

Material Breakdown: Suitable Applications for Metal and Plastic Buckles

Based on the material, buckles can be categorized as metal and plastic, each with its own specific application.

Metal buckles offer both durability and quality, and their functionalities include square buckles, sun-shaped buckles, movable sun-shaped buckles, round rings, oval rings, hook buckles (both rotating and non-rotating), belt buckles, and special-purpose buckles. Electroplating processes are similar to those used for metal pull tabs, with common options including zinc plating, chrome plating, and nickel plating, enhancing both rust resistance and a polished appearance. Metal buckle specifications are primarily determined by width, height, and wire diameter. For specialized styles, consult the manufacturer's catalog (mold variations between manufacturers can result in slightly different specifications). These buckles are suitable for business luggage, outdoor hardshell bags, belts, and other products that demand high quality and texture.

Plastic buckles, on the other hand, offer advantages such as lightweight and cost-effectiveness. Functions include sun-shaped buckles, square buckles, ladder buckles, insert buckles, hook buckles, multi-function buckles, cord buckles, and plastic reinforcements. They are primarily made of plastic steel and nylon. Plastic steel offers a high cost-effectiveness and is suitable for everyday casual luggage. Nylon, while offering greater toughness and aging resistance, is slightly more expensive and is often used in high-use or safety-critical applications such as outdoor luggage and children's backpacks.

When choosing luggage, buckles may be easily overshadowed by the material and fit, but these inconspicuous components hold the key to a bag's durability. A buckle that passes rigorous tensile and temperature tests can extend a bag's lifespan by over 30%. ng and durable.

Choose Carol Metal

Carol Metal's buckle hardware range is comprehensive, accurately matching diverse application needs: whether you need flat adjuster buckles or rectangular adjuster buckles for adjusting webbing length; D-shaped carabiner hooks or metal side release buckles for fixing and hanging; double-ended pin buckles or rose belt buckles for waist belts; roller buckles (including metal roller buckles) for smoother operation; Metal Arch Bridge Buckles or Arch Bridge Buckles that combine structure and aesthetics; or detailed accessories like metal tri-glide sliders and flat rectangle rings, from luggage, apparel to outdoor gear, from daily necessities to professional equipment, we can precisely meet every type of buckle requirement you have.

What’s more, we focus on customization services + bulk wholesale supply: you can put forward customization needs based on product design, size specifications, and surface finishes (such as electroplating, silk-screen printing), and we produce on demand to ensure the buckles integrate perfectly into your product system.

As a professional manufacturer, we never compromise on quality. Our metal buckles are made of high-quality materials, balancing durability and rust resistance, and are suitable for different environments (such as high and low temperatures). We strictly control every process from production to delivery to ensure each batch of buckles can stand the test of real-world use.

If you are looking for a reliable buckle hardware partner, whether it’s for product consultation, customization solutions, or quotation requests, take action now! For inquiries and purchases, send an email directly to tony@carolxiao.com and let us know your needs. Carol Metal will respond promptly to provide you with exclusive buckle hardware solutions and help upgrade your products!

References

1. Harper, C.A. (2002). Handbook of Plastics, Elastomers, and Composites (4th ed.). McGraw-Hill Professional. ISBN: 9780071384766.

2. Rosato, D.V., Rosato, M.G., & Rosato, D.V. (2004). Plastics Engineered Product Design (3rd ed.). Elsevier.

3. Osswald, T.A., & Menges, G. (2012). Materials Science of Polymers for Engineers (3rd ed.). Hanser Publishers. ISBN: 9783446412335.

4. Strong, A.B. (2016). Plastics: Materials and Processing (4th ed.). Pearson Education. ISBN: 9780133821782.

5. Davis, J.R. (Ed.). (1999). Metals Handbook: Properties and Selection of Nonferrous Alloys and Special-Purpose Materials. ASM International.

_1753256285958.png)

_1754990596544.webp)