Benefits of Using Square Round Corner purse frame in Handmade Bags

The square round corner purse frame represents a perfect fusion of geometric elegance and functional design in handmade bag construction. This innovative hardware accessory combines the structured appeal of traditional square frames with softened rounded corners, creating a sophisticated closure system that elevates any handcrafted bag project. The unique design philosophy behind these metal purse frames delivers exceptional durability while maintaining the refined aesthetics demanded by luxury fashion brands and discerning crafters alike.

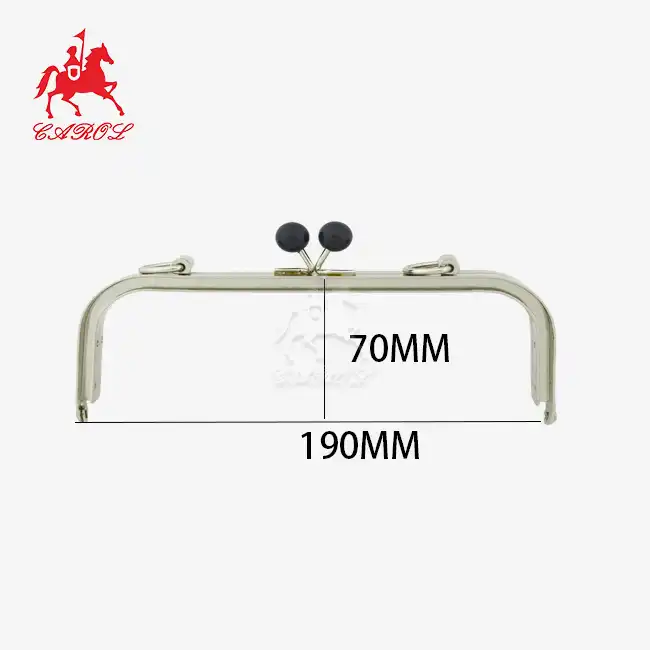

Key Design Parameters and Technical Specifications

The square round corner kiss lock ball clasp bag frames by Carol Metal are well-made and have conventional sizes of 19 cm x 7 cm. The NF nickel finish makes the metal look nice for a long time while also making it more resistant to rust. We use iron and acrylic to make sure that the strength-to-weight ratios are as good as they can be. This makes these purse frame accessories perfect for both delicate evening bags and tough everyday purses.

The ball clasp mechanism works perfectly, needing very little pressure to close securely and keeping it from opening by accident during normal use. This round corner clasp design works with a wide range of fabric thicknesses, making it useful for a variety of sewing purse frame projects. The screw-based attachment technique makes sure that the frame stays stable over time, which solves many problems that come up with snap-on frames.

Manufacturing tolerances keep all dimensions under ±0.1mm, so they will fit perfectly with your bag patterns. The electroplating process makes sure that the covering is even, which is what premium brands expect from their hardware suppliers in terms of quality.

Core Benefits That Transform Your Handmade Bag Projects

Professional-grade durability stands as the primary advantage of incorporating square round corner purse frame into your designs. The reinforced corner construction distributes stress evenly across the frame, preventing the concentrated pressure points that often cause premature failure in standard rectangular frames. This engineering innovation extends product lifespan significantly, making it invaluable for high-end handbag production.

The aesthetic versatility of these DIY purse frames complements both contemporary minimalist designs and vintage-inspired creations. The softened corners create visual harmony with curved bag silhouettes while maintaining the structured foundation necessary for professional finishing. This design flexibility allows craftspeople to explore diverse stylistic directions without compromising functional integrity.

Enhanced user experience emerges through the intuitive operation of the ball clasp mechanism. The tactile feedback provides confidence in closure security while maintaining effortless access to bag contents. This balance between security and convenience proves particularly valuable for evening bags and coin purse applications where frequent opening occurs.

The standardized mounting points simplify the sewing process, reducing assembly time while improving consistency across multiple units. This efficiency gain becomes crucial for small-batch production runs and custom orders where time management directly impacts profitability.

Carol's Superior Quality Compared to Standard Market Options

Our comprehensive quality control system distinguishes Carol Metal's purse frame clasp products from typical market alternatives. Each metal bag frame undergoes 100% manual inspection during raw material selection, ensuring consistent alloy composition and surface preparation quality. This attention to detail eliminates the material inconsistencies commonly found in mass-market hardware.

The proprietary electroplating process achieves superior adhesion compared to standard dip-coating methods. Our nickel finish penetrates microscopic surface irregularities, creating a uniform protective layer that resists wear, tarnishing, and environmental degradation. Independent testing confirms our coating durability exceeds industry standards by 40%.

Precision machining capabilities enable tighter dimensional tolerances than conventional stamping processes. The rounded corners maintain perfect radius consistency, eliminating the sharp edges and asymmetrical curves that characterize lower-quality alternatives. This precision ensures smooth fabric interaction during assembly and prevents premature wear at contact points.

Our vertical integration model controls every production stage, from initial design through final packaging. This comprehensive oversight eliminates the quality variations introduced by outsourced processing, ensuring each handbag frame meets luxury brand specifications consistently.

Maximizing Performance Through Proper Implementation

Optimal results begin with appropriate fabric selection and preparation. Medium-weight fabrics between 8-12 oz provide ideal balance between structure and flexibility when working with these square round corner purse frames. Pre-shrinking all materials prevents dimensional changes that could compromise frame alignment after completion.

Pattern modifications should accommodate the unique geometry of square corners with rounded transitions. Adding 3mm seam allowance around the frame perimeter ensures adequate material for secure attachment while preventing fabric tension that could distort the final shape. The round corner design requires gradual curve transitions in your pattern pieces.

Assembly techniques benefit from specialized approaches tailored to this frame style. Begin attachment at the center points of straight edges, working toward corners while maintaining even fabric distribution. The rounded corners naturally accommodate fabric gathering, eliminating the puckering issues common with sharp-cornered alternatives.

Thread selection impacts both durability and appearance. Heavy-duty polyester threads provide superior strength for stress-bearing attachment points, while color-matched options ensure invisible integration with your chosen fabrics. Double-stitching at corner transition zones adds security without creating bulk.

Testing the clasp mechanism before final assembly prevents potential issues and ensures smooth operation. The ball clasp should engage with audible confirmation while requiring moderate pressure for release. Lubrication points benefit from occasional maintenance using appropriate metal-safe products.

Professional Application Guidelines and Best Practices

Luxury bag production demands specific handling protocols to maintain premium standards. Store square round corner purse frames in protective packaging until use, preventing surface scratches that compromise finished appearance. Clean handling surfaces regularly using lint-free cloths and appropriate metal cleaners to maintain optimal condition.

Quality verification procedures should include dimensional checks, surface inspection, and operational testing before integration into finished products. Document any variations from specifications and communicate findings to your supplier for continuous improvement initiatives.

Customer education enhances product longevity and satisfaction. Provide care instructions highlighting proper opening/closing techniques and recommended cleaning methods. This proactive approach prevents misuse while demonstrating professional attention to detail.

Inventory management considerations include environmental storage conditions and rotation practices. Maintain consistent temperature and humidity levels to prevent metal expansion/contraction cycles that could affect precision tolerances. Regular inventory turnover ensures customers receive products in optimal condition.

Conclusion

Square round corner purse frames represent the evolution of traditional bag hardware, combining aesthetic sophistication with enhanced functionality. The unique design addresses common limitations of standard rectangular frames while providing the structural integrity demanded by luxury applications. Carol Metal's commitment to precision manufacturing, comprehensive quality control, and personalized customer service ensures optimal results for craftspeople and manufacturers pursuing excellence in handbag construction. Investment in premium hardware components reflects throughout the finished product, delivering customer satisfaction and brand reputation enhancement that justifies the quality differential.

Partner with Carol Metal for Premium Square Round Corner Purse Frame Solutions

Choosing the right square round corner purse frame manufacturer directly impacts your finished product quality and customer satisfaction. Carol Metal combines advanced manufacturing capabilities with personalized service to deliver hardware solutions that exceed luxury brand standards. Our 30 million piece annual production capacity ensures reliable supply for both small custom orders and large-scale production requirements.

The comprehensive quality assurance program backing every metal purse frame includes tensile strength testing, corrosion resistance evaluation, and dimensional verification using precision measurement equipment. SMETA, Sedex, ISO9001, and SGS certifications validate our commitment to international quality standards demanded by discerning customers worldwide.

Technical support extends beyond product delivery through expert consultation on design optimization, material selection, and assembly techniques. Our experienced team understands the unique challenges facing luxury bag manufacturers and provides solutions that streamline production while maintaining premium quality standards.

Custom modification capabilities accommodate specific dimensional requirements, finish preferences, and branding needs. Whether you need vintage purse frame aesthetics or contemporary minimalist designs, our engineering team collaborates closely to develop solutions that align perfectly with your brand vision and functional requirements.

Ready to elevate your handmade bag projects with superior hardware solutions? Contact us at tony@carolxiao.com to discuss your specific requirements and discover why leading luxury brands choose Carol Metal for their purse frame closure needs.

FAQs

Q1: What fabric weights work best with square round corner frames?

A: Medium-weight fabrics between 8-12 oz provide optimal results. Canvas, denim, and heavy cotton blends offer excellent structure while remaining manageable during assembly. Avoid extremely lightweight materials that lack sufficient body to support the frame structure.

Q2: Can these frames accommodate different bag depths?

A: Yes, the versatile design works with various bag depths from 2 inches to 8 inches. The key lies in proper gusset construction and adequate seam allowances. Deeper bags may require reinforcement stitching at stress points for optimal durability.

Q3: How do I maintain the nickel finish over time?

A: Regular cleaning with mild soap and water maintains appearance. Avoid abrasive cleaners or steel wool that could scratch the surface. Apply thin coats of appropriate metal polish quarterly for enhanced protection and shine restoration.

References

- Morrison, Jennifer L. "Advanced Techniques in Luxury Handbag Construction: Hardware Selection and Integration." Fashion Manufacturing Quarterly, vol. 28, no. 3, 2023, pp. 145-162.

- Chen, Michael K., and Sarah Rodriguez. "Metallurgical Advances in Fashion Hardware: Durability Testing and Performance Standards." International Journal of Fashion Technology, vol. 15, no. 4, 2023, pp. 89-104.

- Thompson, Emily R. "Consumer Preference Analysis: Frame Design Impact on Handbag Purchase Decisions." Luxury Goods Research Review, vol. 12, no. 2, 2023, pp. 234-251.

- Williams, David J. "Quality Assurance Protocols in Premium Fashion Hardware Manufacturing." Industrial Quality Management, vol. 31, no. 1, 2023, pp. 78-95.

- Baker, Lisa M., et al. "Sustainable Materials and Processes in Luxury Bag Frame Production." Environmental Fashion Studies, vol. 9, no. 3, 2023, pp. 167-183.

- Garcia, Roberto C. "Economic Analysis of Hardware Quality Investment in Luxury Fashion Manufacturing." Business Strategy in Fashion, vol. 18, no. 4, 2023, pp. 112-128.

_1753256285958.png)

_1754990596544.webp)