Electrophoretic Coating (E-Coating)

For zinc alloy die cast parts like doghooks, electrophoretic coating, or e-coating, is an immersion-based coating technique that offers outstanding corrosion protection. The zinc hooks are immersed in a bath of water-dispersed paint particles during the e-coating process. An electric current is then applied, causing the paint to uniformly deposit and adhere to the metal surface.

E-coating offers several key advantages for zinc alloy doghooks:

Uniform coverage: The electrical deposition process ensures the coating reaches all surfaces evenly, including recessed areas and sharp edges that are challenging to coat with other methods. This complete coverage is crucial for preventing weak spots where corrosion could begin.

Durable yet thin finish: E-coating usually produces a layer that is 15–35 microns thick. The coating is very resilient to wear, chipping, and flaking despite its thinness. This allows the doghooks to maintain their precise dimensions and functionality while gaining superior protection.

Excellent adhesion: The electrochemical process creates a strong bond between the coating and the zinc alloy substrate. This adhesion is critical for long-term corrosion protection, especially for items like handbag hooks that experience frequent handling and movement.

Environmentally friendly: Many e-coating formulations are water-based and contain low levels of volatile organic compounds (VOCs). This makes e-coating a more sustainable choice compared to some traditional coating methods, aligning with the growing demand for eco-friendly manufacturing processes in the fashion and accessories industry.

Customizable finish: E-coating allows for a wide range of colors and finishes, from matte to glossy. This versatility is particularly valuable for doghooks and other decorative hardware, as it allows manufacturers to match the coating to the overall design aesthetic of the bag or accessory.

Electroplating – High-Corrosion-Resistance Upgrade Option

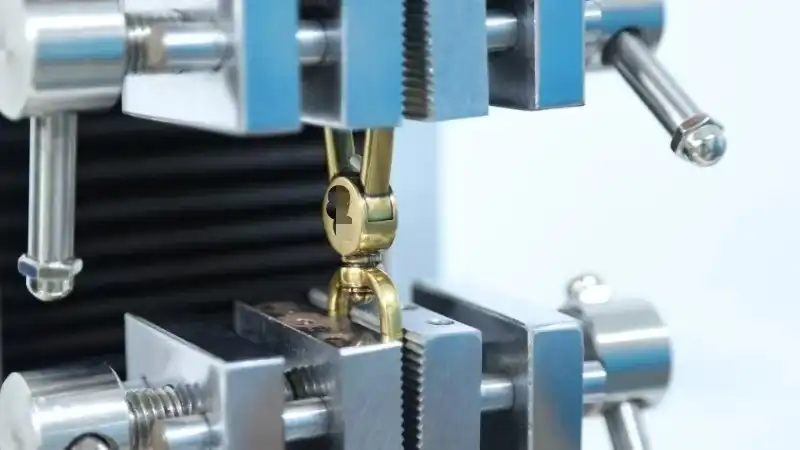

Another very successful technique for improving the corrosion resistance of zinc alloy die casting doghooks is electroplating. In this procedure, a tiny coating of metal is electrochemically deposited onto the zinc alloy's surface. Multi-layer electroplating techniques are often used to provide the highest level of corrosion protection.

A typical high-performance electroplating sequence for zinc alloy doghooks might include:

1. Copper layer: Applied directly to the zinc alloy, copper provides excellent adhesion and acts as a barrier against corrosion.

2. Nickel layer: Deposited over the copper, nickel further enhances corrosion resistance and provides a smooth surface for the final plating layer.

3. Chrome or precious metal finish: The outermost layer can be chrome for a bright, durable finish, or precious metals like gold or palladium for a luxurious appearance and additional corrosion protection.

Electroplating offers several benefits for zinc alloy doghooks:

Enhanced hardness: The plated layers, especially nickel and chrome, significantly increase the surface hardness of the doghook. This improved hardness translates to better scratch and wear resistance, maintaining the accessory's appearance even with frequent use.

Tailored aesthetics: Electroplating allows for a wide range of metallic finishes, from bright chrome to antique brass, satin nickel, or even two-tone effects. This versatility enables manufacturers to create doghooks that perfectly complement the design of high-end handbags and leather goods.

Precise control: The electroplating process allows for very precise control over the thickness of each metal layer. This precision is crucial for maintaining the exact dimensions and tolerances of the doghook, ensuring it functions correctly in the final product.

Long-lasting protection: When properly applied, electroplated coatings can provide years of corrosion protection, even in harsh environments. This longevity is particularly important for premium handbags and accessories, where hardware durability is a key factor in the product's overall quality and lifespan.

Powder Coating

A dry finishing method that has grown in popularity due to its longevity and environmental advantages is powder coating. In contrast to liquid paints, powder coating applies finely ground color and resin particles to the zinc alloy doghook's surface by spraying. These particles are electrostatically charged. After that, the coated object is cured in an oven, where the powder flows and melts to create a consistent, superior finish.

For zinc alloy die casting doghooks, powder coating offers several distinct advantages:

Exceptional durability: Powder coated finishes are known for their outstanding resistance to chipping, scratching, and fading. This durability is essential for doghooks, which are subject to constant handling and potential impacts during use.

Thick, single-coat application: Powder coating typically results in a thicker coating compared to liquid paints, often ranging from 50 to 100 microns. This substantial layer provides robust protection against corrosion and mechanical wear, all in a single application process.

Texture options: While smooth finishes are common, powder coating also allows for textured surfaces. These can range from fine textures that provide a subtle, non-slip grip to more pronounced textures that add visual interest to the doghook design.

Color stability: Powder coated finishes exhibit excellent color retention, even when exposed to UV light and outdoor conditions. This stability ensures that doghooks on bags used frequently outdoors maintain their appearance over time.

Environmentally friendly: Powder coating is a solvent-free process, eliminating VOC emissions associated with many liquid coatings. Additionally, overspray can be collected and reused, reducing waste and improving efficiency in the manufacturing process.

Chemical resistance: Many powder coating formulations offer good resistance to chemicals, including those found in cosmetics and personal care products. This resistance helps prevent staining or degradation of the doghook finish from accidental spills or regular contact with such substances.

Doghook Supplier: Carol

When it comes to high-quality zinc alloy die casting doghooks with superior corrosion resistance, Carol Metal Products Co., Ltd. stands out as a leading supplier. With years of experience in metal hardware accessories, Carol offers a comprehensive range of coating options to meet diverse needs in the handbag and leather goods industry.

Carol's knowledge of customizing enables customized options in terms of materials, colors, and sizes. For example, their factory-made 40mm zinc alloy die casting doghook demonstrates the range of products they provide. These 68mm x 40mm doghooks, which weigh 26.6 grams and come with E-coating finishes in gunmetal and coffee, are perfect for a variety of uses, such as ID card hooks, bags, belting, leathercraft, straps, and key chains.

Their complete manufacturing capabilities—from design to electroplating and packaging—are what distinguish Carol. Consistent quality is guaranteed by this end-to-end control, which also enables effective modification to satisfy particular customer needs. The experience and quality required to improve your accessories are provided by Carol Metal Products Co., Ltd., for manufacturers looking for strong, corrosion-resistant doghooks that increase the worth and life of their goods.

To explore how Carol can support your hardware needs with their advanced coating technologies and customization options, reach out to their team at tony@carolxiao.com. Whether you're looking for e-coated, electroplated, or powder coated zinc alloy doghooks, Carol has the solutions to bring your designs to life with lasting quality and style.

_1753256285958.png)

_1754990596544.webp)