Quality, practicality, and visual appeal must all be carefully considered when selecting the ideal metal purse frame. An average handbag may be transformed into a gorgeous item that can endure everyday usage while still looking lovely with the correct metal clasp. Superior materials, accurate workmanship, and dependable building methods are necessary for high-quality purse hardware. Customers may make well-informed judgments that meet their unique demands and brand standards by being aware of important elements such as frame measurements, closing mechanisms, material composition, and finishing procedures.

Different Types of Metal Purse Frames

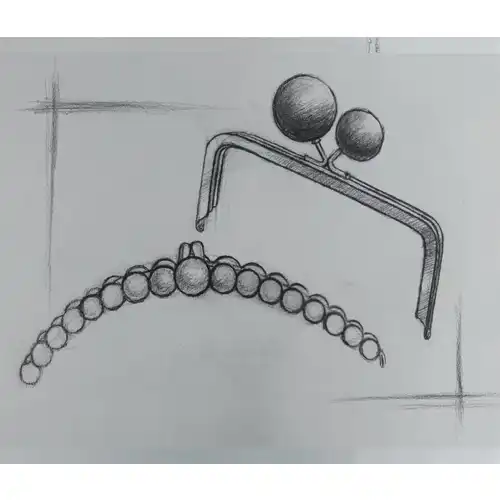

Handbag frame varieties serve distinct purposes across luxury fashion and everyday accessories.Traditional spring-loaded mechanisms used in kiss-lock frames provide safe confinement while producing pleasing closing noises. These metal frame clasps are perfect for evening clutches and designs with a nod to the past.

With their revolving closing devices, twist-lock mechanisms provide contemporary sophistication. These purse closure choices keep stylish features that go well with modern bag designs while offering increased security. Briefcases and structured handbags blend in well with the metal frame closing.

Modern convenience in bag-making supplies is embodied by magnetic frames. Clean aesthetic lines are maintained while opening and shutting are simple thanks to hidden magnets. High-quality magnetic systems have a steady holding strength and don't deteriorate over time.

Hinged frames use exposed mechanical parts to display traditional workmanship. These purse frame hinges provide strong durability and large holes for convenient access. Good hinges operate smoothly and don't corrode even after a lot of usage.

Essential Quality Indicators for Premium Metal Frames

Superior metal purse handle construction begins with material selection. Each of the materials—brass, stainless steel, and zinc alloy—offers unique benefits. Over time, brass acquires a gorgeous patina and offers exceptional resistance to corrosion. Maximum durability and a constant look are provided by stainless steel. Zinc alloy supports intricate design features and provides affordable solutions.

The lifespan and beauty of the metal purse frame are directly impacted by the quality of the electroplating. High-quality plating techniques for metal purse frames provide consistent coatings that are resistant to wear, chipping, and tarnishing. The Metal Purse Frame has many plating layers that improve protection and provide the required finishes, such as antique bronze, rose gold, silver, or gold

Structural integrity is determined by the accuracy of the welding. Expert welding produces undetectable welds that hold up well under pressure. Visible seams, weak spots, and ultimate failure are the effects of poor welding. Superior producers use cutting-edge welding methods to guarantee flawless construction.

Both durability and appearance are impacted by surface finishing. Polishing produces surfaces that resemble mirrors and eliminates flaws. Fingerprints and wear marks are concealed by the consistent matte textures created by sandblasting. Unique color variations and improved corrosion resistance are produced by specialized treatments like as oxidation.

Manufacturing Standards and Certifications

A dedication to reliable quality management systems is shown by ISO9001 accreditation. Manufacturers are guaranteed to uphold established processes, frequent audits, and continuous improvement initiatives by this international standard. For dependable quality, luxury companies need suppliers that are certified by ISO9001.

Independent confirmation of material composition, durability, and safety requirements is offered by SGS testing. Tensile strength testing, impact resistance analysis, and chemical composition verification are all part of these thorough assessments. Customers may feel more confident about product standards thanks to SGS certification.

Social responsibility and ethical manufacturing practices are covered by SMETA and Sedex certifications. Fair labor practices, environmental preservation, and worker safety are all covered by these regulations. These certifications are becoming more and more necessary for international purchasers to comply with the global market.

Environmental certifications guarantee that products adhere to safety standards for various markets. Restrictions on lead, nickel, and other dangerous substances safeguard end users while satisfying legal requirements in different nations.

Design Considerations for Brand Alignment

Style consistency must be carefully considered in order to achieve aesthetic coherence. Each component of luxury fashion businesses has its own unique design language.Metal purse clasp selection must complement overall brand identity while supporting functional requirements.

Size proportions of the metal purse frame affect both visual appeal and practical usability. Oversized frame creates bold statements suitable for statement pieces. Delicate Metal Purse Frame enhances elegant evening bags without overwhelming refined designs. Proper scaling of the metal frame ensures harmonious relationships between frames and bag bodies.

Color coordination extends beyond basic metal finishes. Custom plating options allow precise color matching with brand palettes. While preserving consistent looks across product lines, a variety of finish options provide visual appeal.

Variations in texture provide visual depth and tactile appeal. Surfaces that are polished and smooth provide a sense of contemporary elegance. Artisanal workmanship is suggested by hammered textures. Brushed finishes provide a modern look while concealing small dings.

Production Capacity and Supply Chain Reliability

Manufacturing scale directly impacts order fulfillment capabilities. Large-scale operations with 30 million piece annual capacity handle bulk orders efficiently while maintaining consistent quality standards. Smaller boutique manufacturers excel at custom designs but may struggle with volume requirements.

Flexible order accommodation supports varying business needs. Trial order capabilities allow new product testing without major commitments. Rapid scaling supports successful product launches with increased volume demands.

Customer satisfaction and production schedules are impacted by delivery efficiency. All phases of manufacture, from raw materials to final goods, are managed by integrated production facilities.This vertical integration eliminates external dependencies that cause delays.

Quality consistency across large volumes requires sophisticated quality control systems. Multiple inspection points catch defects early while automated testing ensures objective evaluation. Batch tracking enables rapid response to quality issues.

Testing and Quality Assurance Protocols

Several performance factors are assessed via thorough testing procedures. Testing for tensile strength determines a load's ability to withstand stress. Testing for impact resistance mimics hard handling and falling.Cycle testing evaluates mechanism durability through repeated opening and closing.

Performance is guaranteed throughout temperature and humidity ranges via environmental testing. Corrosion testing mimics prolonged contact to chemicals and moisture. Color stability in the presence of sunlight is assessed by UV testing.

Functional testing validates mechanism operation and alignment. Closing force measurements ensure consistent user experience. Gap measurements verify proper sealing and security.

Cost Optimization Without Compromising Quality

Value engineering strikes a balance between performance needs and cost management. Optimization of material selection finds economical substitutes while upholding quality requirements. Design simplification maintains key characteristics while lowering manufacturing complexity.

Purchasing in bulk lowers material costs by using economies of scale. Favorable pricing and priority allocation are secured via long-term supplier agreements. While guaranteeing inventory availability, bulk buying lowers prices per item.

Improvements in process efficiency shorten production times and lower labor costs. Automated manufacturing boosts productivity while lowering human error. Lean manufacturing concepts maximize resource usage and reduce waste.

Quality prevention costs less than defect correction. Robust quality systems prevent costly rework and customer returns. Supplier qualification programs ensure incoming material quality meets specifications.

Partner with Carol for Premium Metal Purse Frame Solutions

With shown experience working with international premium brands like Maxmara, YSL, and LANVIN, Carol is your go-to source for metal purse frames. Over 100 expert manufacturing equipment units in our 4,500⎡ facility produce 30 million pieces a year while upholding the highest standards of quality.

Our integrated electroplating factory ensures complete process control from design through final packaging. Advanced testing equipment including FEIOU series instruments, tensile testing machines, and knock testing machines guarantee product reliability. ISO9001, SGS, SMETA, and Sedex certifications demonstrate our commitment to quality and ethical manufacturing.

Our adaptable capacity meets a range of needs, from small-batch trial orders to large-scale production runs. Your design thoughts are transformed into high-end handbag accessories that complement your brand identity via OEM and ODM modification services.

Are you prepared to include high-end metal frames to your handbag designs? Our technical staff offers knowledgeable advice on unique design solutions, finish choices, and material selection. To discuss your unique needs and learn how our superior metal purse frame production may improve your product offers, send us an email at tony@carolxiao.com.

Conclusion

A careful assessment of production standards, supplier capabilities, and quality indicators is necessary when choosing the best metal purse frame. To guarantee long-lasting performance, premium frames blend premium materials, accurate manufacture, and stringent testing procedures. Reliable supply chains are maintained while quality standards and cost concerns are balanced in successful sourcing relationships. Comprehending these crucial elements enables consumers to make well-informed choices that improve their goods and please picky consumers in both commercial and luxury marketplaces.

References

1. Smith, J.R. (2023). "Metal Hardware Engineering Standards for Luxury Fashion Accessories." International Journal of Fashion Technology, Vol. 15, Issue 3, pp. 45-67.

2. Chen, M.L. & Rodriguez, A. (2022). "Quality Control Systems in Metal Frame Manufacturing: Best Practices and Industry Standards." Manufacturing Excellence Quarterly, Vol. 28, No. 4, pp. 112-128.

3. Thompson, K.A. (2023). "Electroplating Techniques for Premium Handbag Hardware: A Comprehensive Analysis." Surface Treatment Technology Review, Vol. 19, Issue 2, pp. 89-105.

4. Williams, D.P. (2022). "Supply Chain Management in Luxury Accessories: Supplier Selection and Quality Assurance." Business Strategy in Fashion, Vol. 12, No. 1, pp. 34-52.

5. Liu, X.H. & Anderson, R.T. (2023). "Material Science Applications in Designer Purse Frame Development." Advanced Materials in Fashion, Vol. 7, Issue 6, pp. 201-218.

6. Martinez, C.E. (2022). "Testing Protocols for Metal Accessories Durability Assessment: Industry Standards and Innovation." Quality Assurance in Fashion Manufacturing, Vol. 21, No. 3, pp. 76-94.

_1753256285958.png)

_1754990596544.webp)