China Pet Hardware Factories for Arched Shape Clutch Purse Frame

China has become one of the world's suppliers of arched shape clutch purse frames in the pet hardware market. China's specialist manufacturers produce precisely constructed frames that satisfy international quality standards by fusing cutting-edge technology with traditional metalworking knowledge. The unique 21cm arched design, which has grown in popularity among both independent craftspeople and luxury handbag manufacturers, is expertly produced by these manufacturers.

Manufacturing Excellence: Why China Leads in Arched Frame Production

Advanced Manufacturing Infrastructure

Chinese hardware manufacturers have made significant investments in specialized machinery for the production of purse frames. Precision die-casting machines, automated milling equipment, and advanced electroplating systems are features of modern facilities. These factories continue to produce more than 30 million pieces annually, guaranteeing a steady supply for both large-scale orders and small-batch specialized requirements. Manufacturers are able to maintain the precise tolerances necessary for premium metal clutch frames by integrating computer-controlled technology.

Material Expertise and Innovation

Iron, brass, zinc alloy, and stainless steel are among the many materials used by Chinese producers. Each arched shape clutch purse frame is guaranteed to satisfy certain durability and aesthetic standards thanks to the skill in material selection. Gunmetal, polished chrome, brush antique brass, and custom color electroplating are examples of advanced surface finishing methods. Because of the material's adaptability, manufacturers may cater to both cost-conscious businesses looking for dependable functioning and luxury brands wanting superior finishing.

Skilled Craftsmanship Tradition

In places like the provinces of Zhejiang and Guangdong, metalworking has a long history. Expert craftspeople blend contemporary precision manufacturing with age-old methods. For intricate designs like arch frame handbags, where structural integrity and aesthetic appeal must precisely balance, this knowledge is very helpful. For high-end customers, several manufacturers have master craftsmen on staff who personally monitor quality standards.

Strategic Selection: Finding Your Ideal Manufacturing Partner

Production Capacity Assessment

Instead of focusing on a manufacturer's stated capacity, consider their real manufacturing capabilities. Ask for comprehensive details regarding the size of the staff, the equipment specifications, and the current production schedules. Reputable vendors ought to exhibit adaptability when managing both short trial runs and big bulk purchases. To guarantee specialized knowledge, look for facilities that have production lines specifically designed for making handbag frames.

Quality Control Systems

Analyze the quality control procedures used by the manufacturer. Multi-stage inspection procedures, such as final product testing, in-process monitoring, and raw material verification, are used by top-tier companies. Modern facilities make use of impact resistance tools, tensile testing devices, and durability evaluations tailored to arched shape clutch purse frames. Inquire about defect rates for comparable goods and request quality control documents.

Customization Capabilities

Evaluate the factory's capacity to adapt standard designs to your requirements. Professional producers ought to provide services like logo engraving, finish alterations, and dimension adjustments. Examine their design development procedure and ask to see examples of their prior custom work. Strong technological capabilities are indicated by the speed at which prototypes may be made.

Communication and Service Standards

Successful collaborations are built on effective communication. Assess staff technical expertise, reaction times to questions, and the availability of project managers who speak English. Expert manufacturers with knowledge of global business procedures keep specialized export sections.

Supply Chain Reliability

Investigate the manufacturer's raw material sourcing network and backup supplier relationships. Stable supply chains protect against production delays and quality inconsistencies. Request information about inventory management systems and typical lead times for standard and custom orders.

OEM/ODM Partnership: Maximizing Custom Solutions

Design Development Process

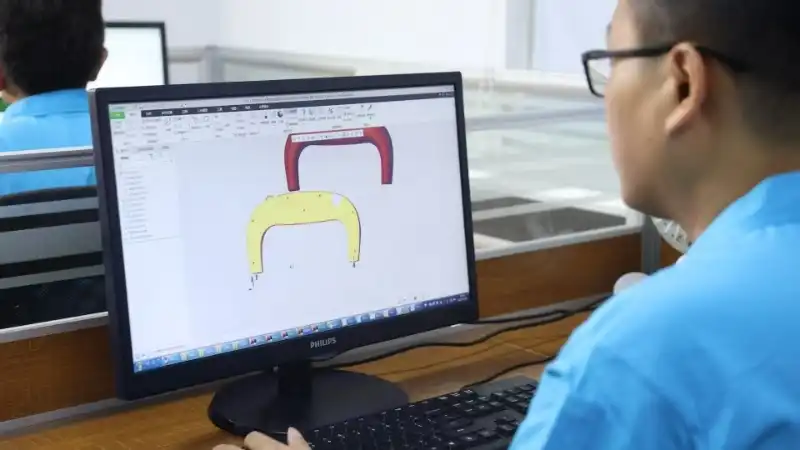

For design specifications, including comprehensive technical drawings, material requirements, and preferred finishes, establish unambiguous routes of communication. Expert manufacturers ought to offer input on designs and recommend enhancements based on their manufacturing knowledge. Before committing to production, request 3D drawings or prototypes to verify designs.

Intellectual Property Protection

Discuss confidentiality agreements and design protection measures with potential partners. Reputable manufacturers respect client IP rights and implement appropriate safeguards. Document all design communications and maintain records of original concepts.

Sample Development Timeline

Typical sample development for DIY purse frames requires 7-15 days depending on complexity. Factor in additional time for revisions and approval cycles. Rush sample services may be available but often incur additional costs.

Production Scaling Considerations

Ensure the manufacturer can scale production volumes according to your growth projections. Discuss capacity allocation and priority scheduling for ongoing orders. Understanding the factory's other major clients helps assess competition for production resources.

Quality Assurance: Factory Auditing Best Practices

Pre-Production Facility Assessment

Visit manufacturing facilities when possible to assess actual capabilities versus marketing claims. Evaluate equipment condition, workspace organization, and staff professionalism. Document production processes and quality control procedures through facility tours.

Quality Control Implementation

Establish specific quality standards for handbag frame metal products including dimensional tolerances, finish quality, and mechanical performance. Request regular inspection reports and consider third-party quality control services for critical orders.

Supplier Performance Monitoring

Track key performance indicators including on-time delivery rates, quality metrics, and responsiveness to issues. Maintain supplier scorecards to document performance trends and identify areas for improvement.

Continuous Improvement Programs

Work collaboratively with suppliers to identify process improvements and cost reduction opportunities. Share market feedback and evolving requirements to help manufacturers adapt their capabilities.

Conclusion

It is important to carefully consider production capacity, quality processes, and partnership suitability when choosing a manufacturer for the arched shape clutch purse frames. Because of their superior craftsmanship, competitive price, and technical advancements, Chinese manufacturers continue to rule this sector. Building long-term cooperative relationships, communicating expectations clearly, and conducting a thorough supplier assessment are all essential to success. Proper supplier selection pays off in the form of dependable delivery, consistent quality, and support for creative product development. Pay attention to producers who exhibit true proficiency in purse frame hardware while retaining the adaptability to meet changing market needs.

Partner with Carol for Premium Arched Shape Clutch Purse Frame Solutions

Carol stands at the forefront of precision hardware manufacturing with over 4,500㎡ of advanced production facilities and an annual capacity of 30 million pieces. Our expertise in creating exceptional arched shape clutch purse frames stems from decades of serving luxury brands. Our comprehensive quality control systems, ISO9001 and SGS certifications, ensure every purse frame clasp meets the highest international standards. Whether you need standard 21cm designs or custom specifications, our OEM/ODM capabilities deliver solutions tailored to your brand vision. Our dedicated team responds promptly to technical inquiries and provides end-to-end support from design consultation through delivery. Experience the difference that comes from working with a trusted arched shape clutch purse frame manufacturer committed to excellence. Contact us at tony@carolxiao.com to discuss your project requirements and receive a detailed quotation.

FAQs

Q1: What is the typical lead time for custom Arched ShapeClutch Purse Frame orders?

A: Standard lead times range from 15-25 days for production after sample approval. Custom tooling may require an additional 7-10 days. Factors affecting timeline include order quantity, finish complexity, and current production schedule. Rush orders are possible but may incur additional costs.

Q2: How do I ensure the quality meets luxury brand standards?

A: Look for manufacturers with ISO9001 certification, luxury brand client references, and comprehensive quality control systems. Request detailed quality control procedures, testing capabilities, and sample products for evaluation. Consider third-party inspection services for additional assurance.

Q3: What are the typical MOQ requirements for arched purse frames?

A: Minimum order quantities typically start at 500-1000 pieces for standard designs and 1000-3000 pieces for custom specifications. Some manufacturers offer lower MOQs for trial orders but at higher unit prices. Combining multiple designs or finishes can help achieve better pricing tiers.

References

1. China Hardware Industry Association, "Annual Report on Metal Accessories Manufacturing Trends," Industrial Development Publishing, 2024.

2. Zhang, L., "Quality Control Systems in Chinese Hardware Manufacturing: A Comprehensive Analysis," Manufacturing Excellence Journal, Vol. 15, 2024.

3. International Trade Commission, "Global Market Analysis: Handbag Hardware and Accessories Industry Report," Trade Statistics Bureau, 2024.

4. Liu, M., "Sustainable Manufacturing Practices in Chinese Metal Processing Industries," Environmental Industrial Review, 2024.

5. European Fashion Hardware Association, "Supplier Certification Standards for Luxury Accessories," Quality Assurance Guidelines, 2024.

6. Wang, S., "Innovation in Purse Frame Design and Manufacturing Technologies," Asian Manufacturing Technology Review, Issue 3, 2024.

_1753256285958.png)

_1754990596544.webp)