China Pet Hardware Factories for Swivel Dog Lead Hooks

China's pet hardware manufacturing industry has become the global supplier in producing high-quality dog lead hooks, swivel clips, and related accessories. With over 65% of the world's pet hardware products manufactured in China, buyers worldwide turn to Chinese factories for their superior production capabilities, cost-effectiveness, and innovative designs.

Manufacturing Excellence: Why China Chooses Dog Lead Hook Production

Advanced Production Infrastructure

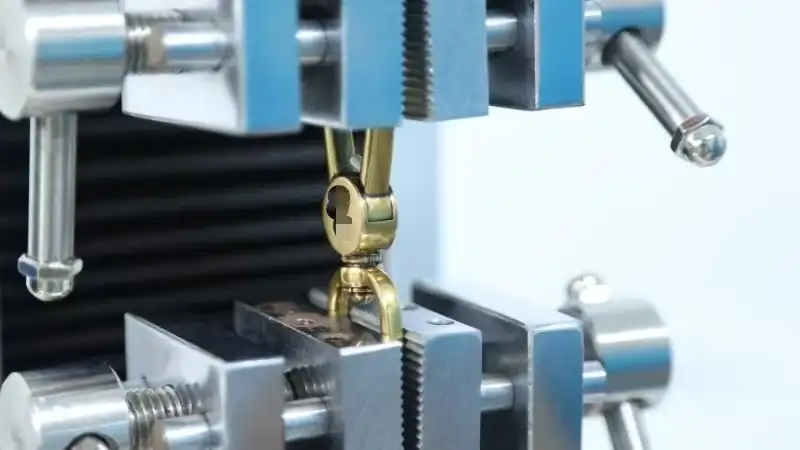

Chinese companies have spent a lot of money on cutting-edge machinery made just for making pet hardware. Modern factories have precision die-casting machines, automated assembly lines, and specific testing equipment that makes sure that millions of units are always of the same high quality. These new technologies let manufacturers make dog lead attachments with exact tolerances and performance standards that are always met.

Material Innovation and Quality

The zinc alloy compositions used in high-end dog collar hooks are always being improved to make them last longer and resist rust. Chinese producers have learned how to use different finishing methods, including as gunmetal, matte gold, and bespoke electroplating, that are safe for use around the world. Adding quality control measures throughout the whole production process makes sure that each dog lead connector fulfills strict performance standards.

Scale and Efficiency Advantages

China's manufacturing infrastructure can handle both large orders and small, flexible requests. The best facilities can make 30 million pieces a year and still be flexible enough to accommodate special orders of as few as 100 units. This flexibility to grow makes Chinese suppliers great partners for enterprises of all kinds, from high-end fashion firms to new pet accessories startups.

Strategic Selection Criteria for Reliable Dog Lead Hook Manufacturers

Production Capacity Assessment

Evaluate dog lead hook manufacturers based on their annual output capabilities and equipment sophistication. Look for facilities with dedicated pet hardware production lines, in-house tooling capabilities, and sufficient capacity to handle your projected volume growth. Manufacturers with 4,500+ square meter facilities typically demonstrate the scale necessary for consistent supply chain reliability.

Quality Management Systems

Examine the manufacturer's quality control processes from raw material inspection to finished dog lead hook testing. Reliable suppliers implement multi-stage inspection protocols including tensile strength testing, impact resistance evaluation, and durability assessments. The presence of specialized testing equipment like knock testing machines and tensile testing apparatus indicates serious commitment to quality assurance.

Customization and Design Capabilities

Check to see if the provider can meet your specific needs for dog lead hooks and other hardware. Top-tier manufacturers offer a wide range of OEM/ODM services, such as helping with design, making prototypes, and scaling up production of custom solutions. Find providers who can make their own molds and have design teams with a lot of experience.

Supply Chain Integration

Put manufacturers who do everything in-house, such electroplating, finishing, and packaging, at the top of your list. This integration makes the company less reliant on outside suppliers and allows for better quality control at every stage of production. Facilities that are integrated usually have shorter lead times and more reliable delivery schedules.

Communication and Service Standards

Check how quickly and accurately the dog lead hook manufacturer responds to your questions throughout your first contacts. Professional suppliers give you clear information about production timelines, detailed product specifications, and material certifications. Exceptional suppliers are generally different from average ones since they can give technical advice and help with problems.

Essential Certification Standards for Pet Hardware Manufacturing

International Quality Certifications

ISO9001 certification demonstrates a manufacturer's commitment to consistent quality management systems. This standard ensures documented procedures for design control, procurement, production, and customer service. Dog lead hook suppliers with ISO9001 certification typically maintain better traceability and continuous improvement processes essential for pet hardware applications.

Product Safety and Material Standards

SGS certification and testing reports validate material safety and performance characteristics of dog leash connectors. These certifications cover aspects like heavy metal content, tensile strength, and environmental safety. RoHS compliance ensures that dog lead hardware meets restrictions on hazardous substances, particularly important for products entering European and North American markets.

Social Responsibility Certifications

SMETA and Sedex certifications indicate ethical manufacturing practices and social compliance. These certifications become increasingly important for brands prioritizing sustainable and responsible sourcing practices. Certified facilities demonstrate commitment to fair labor practices, environmental responsibility, and transparent operations.

Maximizing Success in OEM and ODM Partnerships

Design Development Process

Successful OEM partnerships require clear communication of design specifications, performance requirements, and aesthetic preferences. Provide detailed technical drawings, material specifications, and functional requirements for dog lead hooks or other components. Establish milestone checkpoints throughout the development process to ensure alignment with project objectives.

Intellectual Property Protection

Implement comprehensive intellectual property agreements before sharing proprietary designs or specifications. Document ownership rights for custom tooling, unique designs, and proprietary processes. Clear agreements protect both parties and establish frameworks for long-term collaboration on innovative pet hardware solutions.

Sample Development and Approval

Establish structured sample approval processes with defined acceptance criteria and testing requirements. Multiple iteration rounds may be necessary to achieve optimal performance and aesthetic results. Document all modifications and maintain sample libraries for future reference and quality comparisons.

Leading Supplier Characteristics in the Current Market

Technology Integration and Automation

Premier dog lead hook manufacturers leverage advanced automation and digital quality control systems to enhance productivity and consistency. Investment in modern equipment and process automation demonstrates commitment to long-term competitiveness and quality improvement. These capabilities enable superior performance in producing complex dog lead hardware with tight tolerances.

Sustainability and Environmental Responsibility

Top suppliers use environmental management systems and make products in a way that is good for the environment. This involves making things in ways that use less energy, cutting down on waste, and getting materials in a responsible way. More and more, environmental certifications and sustainability programs are affecting how suppliers are chosen.

Market Responsiveness and Innovation

Top-tier providers are able to quickly adapt to changes in the market and meet the needs of their customers. This includes the ability to quickly create prototypes, change manufacturing schedules, and work together on product development. What sets market leaders apart from commodity suppliers is their ability to come up with new materials, designs, and manufacturing techniques.

China is the leader in making pet gear because of decades of industrial growth, technological progress, and efforts to improve quality. Finding dog lead hooks and other relevant items requires on carefully evaluating suppliers, clearly communicating needs, and building strategic partnerships. The best purchasers are those who know a lot about technology and how to build relationships. They use these skills to form long-term partnerships that benefit both sides. Businesses may take use of China's great manufacturing capabilities while lowering risks and increasing value creation opportunities by following structured review processes and keeping quality, reliability, and innovation at the top of their minds.

FAQs

Q1: How long does it usually take for Chinese manufacturers to make custom dog lead hooks?

A: For existing designs, the standard lead time is 15 to 30 days, and for custom products that need new tooling, it is 30 to 45 days. The number of items ordered, how complicated the customization is, and changes in demand during different seasons can all affect delivery. Setting clear expectations for timelines at the first talks helps make sure that delivery timetables are reasonable.

Q2: How can I check the quality standards of Chinese dog lead hook makers?

A: Ask for thorough quality certificates, such as ISO9001, SGS test reports, and proof that the materials are in compliance. Set up inspections by a third party or audits of the factory to make sure the quality control systems and manufacturing capabilities are up to par. Before submitting larger orders, sample testing and performance verification provide you further peace of mind about quality.

Q3: How many dog lead hardware items do Chinese vendors usually require as a minimum order?

A: The minimum order quantities (MOQs) are very different depending on how complicated the product is and how much customisation it needs. Standard items may only need 500 to 1,000 pieces, but bespoke designs usually need at least 2,000 to 5,000 pieces. Some companies will let you order fewer items for a trial order or to start a new business relationship.

Partner with Carol Metal for Premium Dog Lead Hook Manufacturing Excellence

With an annual production capacity of 30 million pieces and strict quality requirements, Carol Metal is at the top of China's pet hardware manufacturing business. We can make a wide range of products, including 20mm inner width square lobster clasp swivel trigger clip hooks with matte gold and gunmetal finishes that satisfy the standards of luxury brands. We consistently supply high quality across all product categories because we have ISO9001 and SGS certifications. Our 4,500 square meter facility has advanced die-casting machinery, precise testing tools, and the ability to electroplate in-house, which guarantees better product quality and dependable delivery. Our skilled team is here to help you with bulk orders or flexible small-batch production. We offer prompt technical support and customized solutions that meet your exact needs.

Ready to elevate your product line with premium pet hardware solutions? Contact us at tony@carolxiao.com to discuss your dog lead hooks supplier needs and discover how our expertise can drive your business success.

References

1. "Global Pet Hardware Market Analysis and Manufacturing Trends" - International Pet Industry Research Institute, 2024

2. "Quality Standards in Metal Pet Accessories Manufacturing" - China Pet Products Association Technical Committee, 2024

3. "Supply Chain Best Practices for Pet Hardware Sourcing" - Asian Manufacturing Excellence Journal, 2024

4. "Certification Requirements for Pet Hardware in International Markets" - Global Trade Standards Organization, 2024

5. "Innovation Trends in Dog Lead and Collar Hardware Design" - Pet Industry Manufacturing Review, 2024

6. "Sustainable Manufacturing Practices in Chinese Pet Hardware Production" - Environmental Manufacturing Association, 2024

_1753256285958.png)

_1754990596544.webp)