Corrosion test standards for zinc alloy metal dog hook

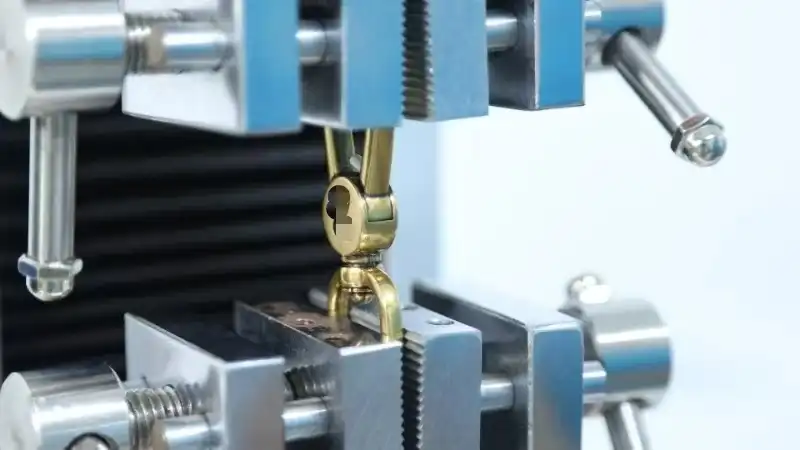

When it comes to manufacturing high-quality metal dog hooks and other hardware accessories, rigorous testing is essential to ensure product durability and performance. At Shenzhen Carol Metal Products Co., Ltd., we take pride in our commitment to quality assurance through comprehensive corrosion testing.

Neutral Salt Spray (NSS) Test: The Industry Standard

The neutral salt spray (NSS) test is universally recognized as the "gold standard" for assessing the corrosion resistance of metal products, an accolade rooted in its strict standardization, high reproducibility, and ability to simulate real-world harsh environments. Governed by internationally authoritative standards such as ASTM B117 (U.S.) and ISO 9227 (global), this accelerated corrosion test mimics the aggressive, salt-laden conditions found in coastal regions, marine environments, or industrial areas with high salt mist. Its core purpose is to evaluate how well metal components, including hardware like metal dog hooks, fasteners, hinges, and structural connectors, can resist degradation when exposed to corrosive elements over time. For end-users and manufacturers alike, the NSS test provides a reliable, comparative metric to validate product durability and ensure long-term performance.

Key aspects of the NSS test include:

- Test duration: Typically ranges from 24 to 1000 hours, depending on the product specifications

- Salt solution: Uses a 5% sodium chloride solution at a neutral pH of 6.5 to 7.2

- Temperature: Maintained at 35°C (95°F)

- Evaluation criteria: Visual inspection for signs of corrosion, rust, or other degradation

Zinc alloy is widely used in dog hook manufacturing due to its cost-effectiveness and moderate corrosion resistance, but its performance can vary drastically in harsh environments. The NSS test is particularly valuable for zinc alloy dog hooks, as it:

①Validates real-world durability: It predicts how the hooks will perform in high-risk scenarios, such as coastal homes (where salt-laden sea breezes persist), outdoor camping (exposure to rain and humidity), or bathroom/laundry areas (moisture and cleaning chemical residues).

②Guides product optimization: Results help manufacturers refine surface treatments (e.g., galvanization, passivation, or organic coatings) to enhance corrosion resistance. For example, if a zinc alloy hook shows rust after 72 hours, adjustments to its galvanized layer thickness can extend its NSS endurance to 168 hours.

③Ensures user safety: Dog hooks are critical for securing pets or heavy items; corrosion-induced cracking or breakage could lead to pet escape, property damage, or injury. The NSS test verifies that hooks maintain structural integrity even under corrosive stress.

Copper Accelerated Acetic Acid Salt Spray (CASS) Test: Intensified Corrosion Simulation

The copper accelerated acetic acid salt spray (CASS) test represents a next-generation, highly aggressive corrosion evaluation method, building on the foundational logic of the Neutral Salt Spray (NSS) test but amplified to simulate extreme, corrosive conditions. Governed by international standards such as ASTM B368 (U.S.) and ISO 9227 (Clause 8, global), this test is specifically designed to accelerate corrosion processes, making it ideal for assessing metal hardware (like metal dog hooks) that may face unforgiving environments: coastal/marine areas with salt-laden fog, industrial zones with acidic pollutants, or outdoor applications exposed to prolonged moisture and temperature fluctuations. Unlike the NSS test (which focuses on "general corrosion resistance"), the CASS test excels at uncovering subtle weaknesses in protective coatings and base metal durability, delivering actionable data in a fraction of the time.

Key features of the CASS test include:

- Test solution: Combines sodium chloride, copper chloride, and acetic acid

- pH level: Maintained between 3.1 and 3.3

- Temperature: Higher than NSS at 49-50°C (120-122°F)

- Accelerated results: Provides faster corrosion data compared to NSS

Zinc alloy is a staple in metal dog hooks manufacturing due to its strength-to-cost ratio, but its inherent corrosion resistance is moderate, relying heavily on protective plated finishes (e.g., nickel, gold, chrome, or brass plating) to withstand harsh conditions. The CASS test is uniquely suited to evaluate these plated zinc alloy hooks, as it targets the "weakest link" in their durability: the integrity of the plating.

Plated finishes often have micro-defects (e.g., pinholes from plating processes, tiny scratches from handling) that are invisible to the naked eye. In neutral NSS conditions, these flaws may not trigger significant corrosion for weeks, but in the CASS test's acidic, copper-enhanced environment, these spots become "corrosion hotspots." The test quickly reveals whether the plating is thick enough, uniform enough, or properly adhered to prevent substrate (zinc alloy) corrosion.

For example, A gold-plated metal dog hook with a 0.5μm thin spot might pass a 72-hour NSS test but show rust at the thin spot after just 24 hours of CASS testing.

Alcohol Rubber Abrasion Testing: Assessing Wear Resistance

While the alcohol rubber abrasion test is not a corrosion evaluation in the traditional sense, it serves as a critical "first line of defense" test for metal hardware like dog hooks. Its core purpose is to validate the durability of surface finishes, plating (nickel, gold, chrome), organic coatings, or paints, by simulating the repetitive mechanical wear these products face in daily use.

For metal dog hooks, an intact surface finish is far more than a cosmetic feature: it acts as a physical barrier against moisture, salt, and contaminants that cause corrosion. Once the finish wears away, the underlying metal (often zinc alloy) is exposed to the elements, leading to rust, pitting, and eventual structural failure. This test ensures that finishes can withstand real-world friction and contact, preserving both the product's appearance and its corrosion resistance over time.

Grounded in industry-accepted protocols (often aligned with guidelines like ASTM D4060 for abrasion resistance or ISO 12137 for coating durability), the Alcohol Rubber Abrasion test is tailored to mimic the most common wear scenarios for dog hooks, from repeated contact with bag straps and keychains to occasional exposure to alcohol-based cleaners (e.g., disinfectants) or sweaty hands.

Key aspects of the Alcohol Rubber Abrasion test include:

- Test apparatus: Uses a rubber wheel or pad soaked in alcohol

- Abrasion cycles: Typically ranges from 100 to 1000 cycles

- Evaluation criteria: Visual inspection and measurement of coating loss

- Finish integrity: Assesses how well plating or other surface treatments adhere to the base metal

For metal dog hooks used in high-wear applications like bag straps or keychains, this test helps ensure that the finish will remain intact and continue to protect the underlying metal from corrosion.

Comprehensive Quality Assurance at Carol Metal Products

When it comes to metal dog hooks and other hardware accessories, corrosion resistance and durability are paramount. At Shenzhen Carol Metal Products Co., Ltd., we go above and beyond industry standards to ensure that our products meet the highest quality benchmarks. From the NSS and CASS tests to abrasion resistance evaluations, every aspect of our dog hooks is scrutinized to guarantee long-lasting performance.

Look no further than Carol Metal Products. Our 22mm inner width metal dog hook, along with our entire range of customizable hardware solutions, offers the perfect blend of durability, style, and functionality.

Contact us today at tony@carolxiao.com to learn more about our products and how we can meet your specific needs.

References

- ASTM B117 - Standard Practice for Operating Salt Spray (Fog) Apparatus

- ISO 9227 - Corrosion tests in artificial atmospheres — Salt spray tests

- ASTM B368 - Standard Test Method for Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing (CASS Test)

- ISO 4538 - Metallic coatings — Thioacetamide corrosion test (TAA test)

- ASTM D4060 - Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser

_1753256285958.png)

_1754990596544.webp)