Even though they are tiny, dog hooks are essential to the practicality and style of many bag designs. Whether it's for a customized carrier, evening bag, or handbag, the material selection may significantly alter both design and function. We'll focus on the benefits of zinc alloy die casting, a technique that has grown in favor recently for creating premium dog hooks and other hardware accessories, while comparing it to stainless steel.

Corrosion Resistance

Corrosion resistance is a critical factor when selecting materials for dog hooks, as these components are often exposed to various environmental conditions. Stainless steel has long been praised for its excellent corrosion resistance, owing to the chromium content that forms a protective oxide layer on its surface. This layer self-heals when damaged, providing continuous protection against rust and other forms of corrosion.

In contrast, zinc alloy provides an alternative method of corrosion protection. Although pure zinc is known to corrode rather quickly, zinc alloys used in die casting techniques are made to significantly boost corrosion resistance. In addition to its corrosion resistance, these alloys often include elements like magnesium, copper, and aluminum that improve the material's overall performance.

One notable advantage of zinc alloy die casting for dog hooks is the ability to apply various surface treatments easily. To further increase corrosion resistance, for example, e-coating techniques may be used. Items like the Factory Customized 40MM Zinc Alloy Die Casting Doghook often have finishes like E-Coating Coffee or E-Coating Gunmetal, which improve appearance and provide an extra degree of defense against corrosive conditions.

In practical terms, while stainless steel may have a slight edge in raw corrosion resistance, the ability to easily apply protective coatings to zinc alloy dog hooks can result in comparable or even superior corrosion resistance in many applications. This is particularly relevant for accessories used in bags that may be exposed to diverse environmental conditions, from humid climates to salty sea air.

Strength & Durability

Both stainless steel and zinc alloy have strong benefits in terms of durability and strength. Because of its high tensile strength and general toughness, stainless steel is a great material for applications that call for sturdy gear. Fashion accessories, including zinc alloy die casting dog hook, are among the various sectors that use it because of its capacity to endure high levels of stress without breaking or deforming.

Zinc alloy, particularly when used in die casting processes, presents a unique combination of strength and ductility. While it may not match the raw tensile strength of stainless steel, zinc alloy offers excellent impact resistance and wear properties. This makes it particularly suitable for dog hooks and other bag hardware that may be subjected to frequent use and occasional impacts.

Another element that often tilts the balance in favor of zinc alloy is its strength-to-weight ratio. For instance, a standard die-cast zinc alloy doghook, like the 40mm kind previously stated, weighs around 26.6 grams and has significant strength. In bag design, where every gram matters toward the product's overall comfort and utility, its lightweight nature is a huge benefit.

Additionally, the fatigue resistance of zinc alloy dog hooks adds to their longevity. Zinc alloy keeps its qualities well over time, in contrast to certain materials that may break easily or lose strength. For hardware used in upscale bags and accessories, where long-term performance is crucial, this feature is very beneficial.

It's worth noting that the strength and durability of zinc alloy dog hooks can be further customized through alloy composition and heat treatment processes. This flexibility allows manufacturers to tailor the material properties to specific requirements, balancing strength, weight, and other performance factors as needed for different bag designs and use cases.

Processability & Design Flexibility

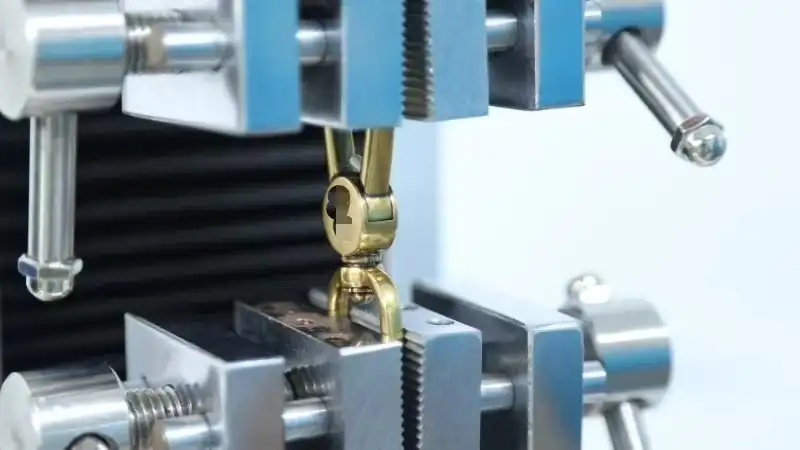

When it comes to processability and design flexibility, zinc alloy die casting offers significant advantages over traditional stainless steel manufacturing methods. The die casting process allows for the creation of complex shapes and intricate details that would be challenging or cost-prohibitive to achieve with stainless steel.

Zinc alloy's lower melting point compared to stainless steel results in several benefits in the manufacturing process. It allows for faster production cycles, reduced energy consumption, and longer die life. These factors contribute to more cost-effective production, especially for large volume orders of dog hooks and other bag hardware accessories.

Products like the Factory Customized 40MM Zinc Alloy Die Casting Doghook are a prime example of the design versatility that zinc alloy die casting offers. With the use of this technique, components as tiny as 68 x 40 mm may be produced with fine features and exact control over dimensions. The variety also extends to surface treatments, where choices like E-Coating Coffee and E-Coating Gunmetal provide both practical advantages and visual appeal.

Another significant advantage of zinc alloy in terms of processability is its ability to be easily plated or finished with various coatings. This characteristic opens up a wide range of design possibilities, allowing manufacturers to create dog hooks that not only perform well but also complement the overall aesthetic of the bag or accessory they're attached to.

The adaptability of zinc alloy extends to customization as well. Product specs state that "sizes, colors, and materials can be customized according to your requirements." In the fashion business, where distinctive designs and brand-specific hardware may differentiate items in a crowded market, this adaptability is crucial.

Stainless steel, while offering its own set of advantages, typically requires more complex and time-consuming manufacturing processes to achieve similar levels of detail and customization. This can result in higher production costs and longer lead times, which can be significant factors in the fast-paced world of fashion accessories.

The processability of zinc alloy also contributes to improved consistency in production. Die casting guarantees that every dog hook satisfies the same exacting criteria for quality and function by enabling high-volume manufacturing with little variance between components. In the cutthroat market for bags and accessories, this consistency is essential to preserving both client happiness and brand reputation.

Zinc Alloy Die Casting Doghook Supplier: Carol

In the realm of high-quality bag hardware, Carol stands out as a leading supplier of zinc alloy die casting doghooks. With years of experience in product design, manufacturing, and sales, Carol has established itself as a trusted partner for handbag, evening bag, and luggage manufacturers worldwide.

Their product line, which includes the Factory Customized 40MM Zinc Alloy Die Casting Doghook, demonstrates Carol's proficiency in zinc alloy die casting. This adaptable part, which weighs 26.6 grams and measures 68 x 40 mm, is a prime example of the ideal ratio of strength, durability, and design flexibility that zinc alloy provides. These doghooks, which come in finishes like E-Coating Gunmetal and E-Coating Coffee, may be used for a variety of things, such as ID card hooks, key chains, and straps and belting.

What sets Carol apart is their commitment to providing comprehensive solutions. From design conception to order processing, manufacturing, plating, and packing, Carol provides a one-stop shop with their own electroplating plant. Consistent quality is guaranteed by this integrated approach, which also permits more customisation to satisfy particular customer demands.

Carol's passion to excellence goes beyond merely product quality. They place a high value on eco-friendly materials, making sure that their zinc alloy doghooks meet international sustainability requirements in addition to being strong and attractive. Because of their dedication, OEM/ODM skills, and several certifications, Carol is a perfect partner for companies wishing to improve their bag hardware.

Carol provides unmatched knowledge and assistance to businesses looking to take advantage of zinc alloy die casting dog hooks for their dog hooks and other bag attachments. Contact their team at tony@carolxiao.com to find out how Carol's zinc alloy solutions may improve your product line. Carol has the capacity to accurately and well realize your idea, whether you're searching for conventional parts or unique designs.

_1753256285958.png)

_1754990596544.webp)