Metal dog hooks are important for both the design and use of bags. A doghook is a useful connector that keeps straps, chains, and other parts of a bag in place while also making it easy to attach and detach them. These strong metal parts let bags work with numerous ways of carrying them, including with shoulder straps or crossbody straps. The swivel mechanism lets the user move naturally while using it, which keeps the strap from twisting and makes it more comfortable. Professional bag makers depend on high-quality dog hooks to make sure that their luxury handbags, everyday purses, and specialized carrying cases last a long time and work perfectly.

Essential Functions of Metal Dog Hooks in Bag Construction

Understanding the practical applications of metal dog hooks reveals their importance in modern bag design. These components bridge the gap between aesthetic appeal and functional necessity.

Strap Attachment and Adjustment Systems

Metal dog hooks are great for attaching removable straps to bag bodies. Users can easily convert between different strap lengths or styles without worrying about security thanks to the hook mechanism. This feature is especially important to luxury brands since it lets one bag do several things. It can change from a handled clutch to a shoulder bag in seconds. The 22mm inner width specification allows for different strap thicknesses while keeping a sleek look that goes well with more complex designs.

Crossbody Conversion Mechanisms

People today want their accessories to be useful in many ways. Dog hooks make it easy to switch from one side of the body to the other right away by giving you solid connection points that equally distribute weight. The swivel action keeps the strap from getting tangled as you move, which is very important for people who are active. Professional tests demonstrate that hooks made of high-quality zinc alloy can handle being attached and detached several times without losing function. This makes them perfect for bags that need to be adjusted often.

Core Applications Across Different Bag Categories

The versatility of metal dog hooks extends across numerous bag types, each presenting unique requirements and challenges.

Luxury Handbag Integration

High-end fashion brands utilize dog hooks as both functional elements and design statements. The slip gold and nickel-free finishes maintain aesthetic consistency while meeting strict quality standards. These hooks enable sophisticated chain attachments that elevate the overall design language. The 45mm x 22mm dimensions provide substantial holding power without overwhelming delicate bag proportions.

Everyday Purse Functionality

Regular purse users benefit from the practical advantages dog hooks offer. Quick strap changes accommodate different outfits and occasions, while the secure locking mechanism prevents accidental detachment. The 11.2-gram weight adds minimal bulk while delivering maximum functionality. Women appreciate the convenience of switching from work-appropriate straps to evening chains without changing bags entirely.

Travel and Outdoor Bag Applications

Travel accessories demand exceptional durability and reliability. Metal dog hooks meet these requirements through robust construction and corrosion-resistant finishes. The attachment system allows travelers to add or remove pouches, organizers, and security cables as needed. Outdoor enthusiasts rely on these hooks to secure gear attachments and adapt their bags for different activities.

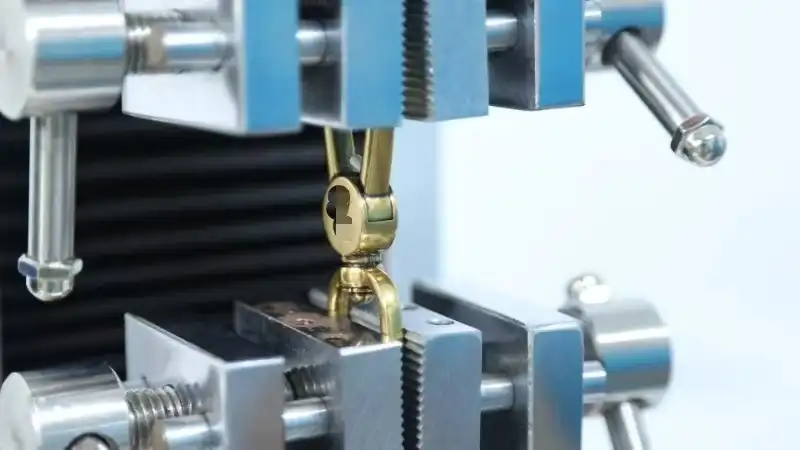

Material Quality and Manufacturing Excellence

The performance of metal dog hooks depends heavily on material selection and manufacturing precision. Understanding these factors helps buyers make informed decisions.

Zinc Alloy Advantages

Zinc alloy offers an optimal balance of strength, weight, and cost-effectiveness. This material resists corrosion while maintaining the structural integrity necessary for repeated use. The alloy composition enables precise molding of complex shapes without sacrificing durability. Professional testing confirms that quality zinc alloy dog hooks exceed industry standards for tensile strength and impact resistance.

Surface Finishing Techniques

Slip gold and nickel-free finishes provide both protection and aesthetic appeal. The electroplating process creates uniform coverage that resists wear and maintains color consistency over time. These finishes accommodate sensitive skin while meeting international safety standards. The smooth surface reduces friction during strap adjustments, extending component lifespan.

Installation and Compatibility Considerations

Proper installation ensures optimal performance and longevity of metal dog hooks in bag applications.

Attachment Point Design

Successful dog hook integration requires careful consideration of attachment point placement and reinforcement. The mounting area must distribute stress effectively to prevent tearing or damage. Professional bag designers incorporate additional backing materials or reinforcement patches at critical stress points. The 22mm inner width accommodates various mounting hardware while maintaining visual proportion.

Strap Compatibility Guidelines

Different strap materials and widths interact differently with dog hook mechanisms. Leather straps require specific edge finishing to prevent premature wear, while fabric straps benefit from reinforced attachment loops. The hook opening must accommodate strap hardware without binding or excessive play. Quality control testing verifies compatibility across common strap configurations.

Quality Standards and Testing Protocols

Professional-grade metal dog hooks undergo rigorous testing to ensure reliability and safety in demanding applications.

Tensile Strength Requirements

Industry standards mandate specific load-bearing capabilities for bag hardware. Quality dog hooks must withstand forces significantly exceeding normal use patterns without failure. Testing protocols simulate extreme conditions including shock loads, repetitive cycling, and environmental stress. The 11.2-gram weight demonstrates efficient material utilization while meeting strength requirements.

Corrosion Resistance Standards

Environmental exposure testing validates finish durability under various conditions. Salt spray tests simulate coastal environments, while humidity chambers replicate tropical climates. UV exposure testing confirms color stability and material integrity over extended periods. These comprehensive evaluations ensure consistent performance across global markets.

Customization Options and Design Flexibility

Modern manufacturing capabilities enable extensive customization of metal dog hooks to match specific brand requirements and aesthetic preferences.

Size and Proportion Variations

Custom sizing accommodates unique design requirements while maintaining functional integrity. Smaller hooks suit delicate evening bags, while larger versions provide enhanced capacity for heavy-duty applications. The standard 45mm x 22mm dimensions serve as a baseline for proportional scaling. Engineering analysis ensures that modified dimensions maintain appropriate strength characteristics.

Finish and Color Customization

Brand-specific finishes enable seamless integration with existing hardware collections. Custom color matching services utilize advanced spectrophotometry to achieve precise color coordination. Specialized textures and patterns add unique design elements while maintaining functional performance. These customization capabilities support brand differentiation in competitive markets.

FAQ

Q1: What weight capacity can metal dog hooks safely support?

A: Quality zinc alloy dog hooks typically support 15-25 pounds of distributed weight when properly installed. The specific capacity depends on mounting method, strap distribution, and hook size. Professional testing validates these limits under controlled conditions.

Q2: How do I maintain the finish quality of metal dog hooks?

A: Regular cleaning with mild soap and water preserves finish integrity. Avoid harsh chemicals or abrasive materials that could damage the electroplated surface. Proper storage in dry conditions prevents premature oxidation and maintains appearance.

Q3: Are metal dog hooks compatible with all strap materials?

A: Most common strap materials work well with quality dog hooks. Leather, fabric, and synthetic straps attach securely when properly configured. The 22mm inner width accommodates standard strap hardware and reinforcement elements effectively.

Partner with Carol for Premium Dog Hook Solutions

Carol Metal stands as a top doghook manufacturer, supplying great quality and service to global brands. Our 4,500㎡ facility has innovative production equipment capable of creating 30 million pieces yearly, assuring consistent supply for both small trial orders and large-scale production runs. The in-house electroplating plant has full control over the whole process, from raw materials to completed goods. This ensures that the quality is always high and fulfills international standards like ISO9001 and SGS certifications.

Ready to enhance your bag designs with premium metal dog hooks? Our expert team provides professional consultation and rapid response to your specific requirements. Contact us at tony@carolxiao.com to discuss your project needs and discover why leading brands trust Carol for their hardware solutions.

Metal dog hooks are important parts of modern bag design since they are versatile, long-lasting, and look good in a lot of different situations. These hardware parts make it possible for functional flexibility while keeping the design intact, whether the bag is a luxury one or an everyday one. Using high-quality materials like zinc alloy, along with precise manufacture and the right finishes, makes sure that the product works well even under tough conditions. The 22mm inner width and 45mm length make it work best with common strap systems while yet being able to meet specific needs. Knowing how to properly install, maintain, and make sure that these parts work with each other will give you the most benefits. As bag design changes, metal dog hooks stay important parts that connect style and function in high-end accessory solutions.

References

1. Johnson, M. "Hardware Components in Luxury Bag Manufacturing: A Technical Analysis." Fashion Industry Quarterly, 2023.

2. Chen, L. "Material Sciences in Fashion Hardware: Zinc Alloy Applications and Performance Standards." International Journal of Fashion Technology, 2022.

3. Rodriguez, A. "Quality Control Protocols for Metal Accessories in High-End Fashion Production." Luxury Manufacturing Review, 2023.

4. Thompson, K. "Electroplating Techniques for Fashion Hardware: Durability and Aesthetic Considerations." Surface Finishing Technology, 2022.

5. Williams, S. "Consumer Preferences in Bag Functionality: The Role of Hardware Components." Fashion Consumer Research, 2023.

_1753256285958.png)

_1754990596544.webp)