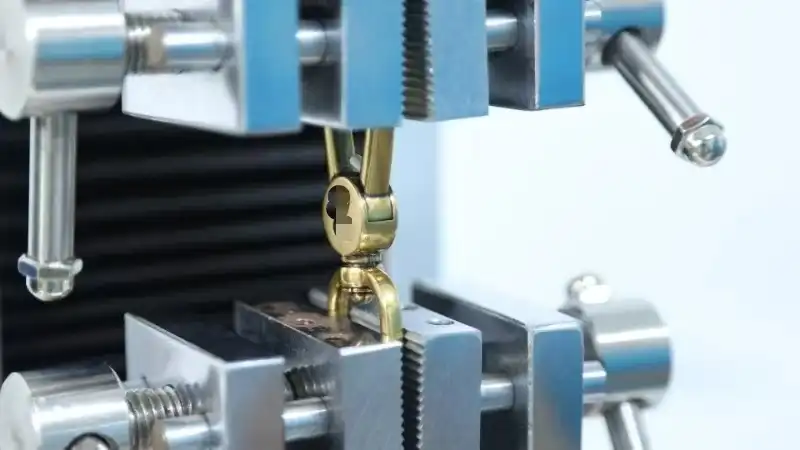

How to assemble the metal dog hook?

In the procurement process of metal dog hooks, assembly and debugging are often regarded as "finishing touches," and they let their guard down, but in fact, this link directly determines the use experience and safety performance of dog hooks. For spring-loaded, rotary and other multi-component dog hooks, even a 0.1mm mating gap deviation or an irregular riveting can lead to problems such as "opening and closing stuck" and "load-bearing falling off", which will eventually lead to complaints and returns of downstream packaging products.

According to the "2024 Hardware Accessories Procurement Quality Report", dog hook quality problems caused by improper assembly and debugging account for 38%, far exceeding the proportion of problems in raw materials and molding links. Therefore, buyers must take assembly and debugging as the "last line of defense" for functional verification, and ensure that the components of each batch of dog hooks are accurate and their functions meet the design requirements through scientific sampling inspection and scenario-based debugging.

Assembly Process: 3 Core Sampling Points

The quality of the assembly process is directly related to the structural stability and service life of the dog hook, and the buyer cannot fully inspect each product, so it is necessary to accurately judge the assembly level of the entire batch of products through the method of "random sampling + key index testing". It is recommended to randomly select 10-20 samples per batch, focusing on the following three key points:

Component Fitting Accuracy

The core of the multi-component dog hook lies in the "seamless cooperation" of each component. Buyers need to use professional tools to detect the gap and movement state according to the structural characteristics of different types of dog hooks:

- Spring dog hook: Focus on detecting the mating gap between the deadbolt and the hook body, and use a feeler gauge to measure to ensure that the gap is ≤ 0.1mm. At the same time, manually open and close the metal dog hook 10-20 times to feel whether the opening and closing process is uniform and smooth, and there is no phenomenon such as "jamming" and "rebound weakness", if there is a lag, it may be a skewed deadbolt installation or a spring groove positioning deviation, and you need to be wary of batch assembly problems.

- Rotary dog hook: The key is to check the fit accuracy of the bearing and the connecting ring, and the clearance should be controlled within ≤0.02mm. The rotational resistance can be tested with a tensile gauge, and the standard value should be ≤ 0.5N, that is, 360° free rotation can be achieved by gently toggling the connecting ring, without "jamming" and "uneven rotation". If the resistance is too large, it may be due to insufficient lubrication of the bearing or foreign objects during installation, which can easily lead to bearing wear and affect the rotation function after long-term use.

Riveting Firmness

The riveting quality of the hook body and connecting ring, deadbolt and hook body and other connection parts is the core guarantee of the load-bearing safety of metal dog hooks. The buyer needs to verify the riveting strength through the "ultimate tensile test", and the specific operation method is:

According to the rated load capacity of the dog hook (such as 5kg for daily models and 20kg for outdoor models), use a pulling machine to apply 1.5 times the rated load capacity (e.g., 15kg for rated 10kg), and observe the state of the riveted joints after 1 minute. The qualification standards are: no loosening, no deformation or falling off of the riveted joint, and the overall structure of the hook body is complete. If the rivet joint cracks or the component displacement, it means that the riveting pressure is insufficient or the riveting position is deviated, and such products are very easy to break due to load-bearing in actual use, which poses serious safety hazards.

Spring Performance

The spring is the "heart" of the spring-loaded dog hook, and its performance directly affects the convenience of opening and closing and the reliability of locking. Buyers need to test from two aspects: "opening and closing force" and "fatigue life":

- Opening and closing force test: Use a dynamometer to measure the force of pressing the deadbolt; the standard range is 15-30N. When the force < 15N, the spring elasticity is insufficient, and the metal dog hook is susceptible to external vibration and automatically opens, causing the hanging items to slip off; When the force > 30N, the user needs to open and close with laborious operation, especially unfriendly to female users, affecting the user experience.

- Fatigue life test: Manually or with the help of equipment to open and close the dog hook 500 times in a row, each time it needs to be fully opened and locked. Check the spring status after the test: the spring is not deformed or broken, and the deadbolt can still rebound quickly and lock tightly, indicating that the spring fatigue performance is up to standard. If the spring is loose and the locking delay occurs, it indicates that the spring material or heat treatment process is unqualified and easy to failure with long-term use.

Functional Debugging

After a properly assembled dog hook is assembled, it must undergo a scenario-based commissioning test to verify its compatibility with the actual needs of the bag. Some dog hooks may meet the requirements in static testing, but may exhibit functional deviations when simulated in real-world use. Purchasers should design a targeted commissioning plan based on the specific application scenarios of the metal dog hook (e.g., shoulder strap connection, external attachment, etc.):

Shoulder Strap Connection Scenario: Functional Stability Under Repeated Pull

When a metal dog hook is used to connect shoulder straps to a bag, it is frequently subjected to repeated pulling and angle changes during daily use. The commissioning method is to connect the dog hook to a bag strap of the appropriate width and apply a 5kg tensile force (simulating the normal load on a person's back) using a tensile testing machine or manually. Repeat the test 100 times, opening and closing the metal dog hook 3-5 times after each pull. Acceptable standards include: the hook remains intact after being pulled, opens and closes smoothly, the spring shows no signs of failure, and the latch is securely locked. If the shoulder strap and hook connection slips or the hook opens and closes with difficulty, check the hook opening width for compatibility with the bag strap (the opening width should be 0.3-0.5cm wider than the bag strap).

External Attachment Scenario: Safety and Stability Under Inclined Loads

Outdoor bags and sports bags often require external attachments, such as water bottles and umbrellas. This can easily cause the hook to tilt due to movement during use. To test the hook, attach a load with a rated load (e.g., a 10kg weight for a rated load of 10kg) to the hook, tilting it at a 45° angle to the load. Hold the hook for 30 minutes. Observe the hook during this time to ensure there is no deformation, no slippage, and no cracks at the connection caused by stress concentration. If the hook opening opens or the load slips, it indicates insufficient hook strength or an improperly designed locking mechanism, failing to meet the safety requirements of outdoor use.

In short, the assembly and commissioning of metal dog hooks is more than a simple matter of "joining parts"; it's a crucial step that affects product safety and user experience. Buyers must abandon the traditional mindset of prioritizing price over craftsmanship and establish a scientific functional verification system through standardized spot checks and scenario-based commissioning. Only in this way can quality risks be mitigated at the source, providing reliable hardware accessories for the quality upgrades of downstream packaging products.

As a leading name in metal hardware manufacturing, Carol Metal brings over a decade of expertise in producing stylish and durable accessories for handbags, luggage, and leather goods. Our 22mm inner width metal dog hook for bags exemplifies our dedication to quality and craftsmanship. Made of zinc alloy with a smooth slip gold or NF nickel finish, it's designed for lasting performance and elegant appeal.

With a fully integrated production system, including our own electroplating facility, we offer one-stop services from design to packaging, ensuring efficiency, customization, and consistent quality control. Serving both domestic and international clients, we are committed to delivering products that enhance your brand's value.

Ready to collaborate with a professional factory that understands your needs? Email us at tony@carolxiao.com and let Carol Metal provide the hardware solutions your business deserves.

References

U.S. Consumer Product Safety Commission. CPSIA Regulatory Requirements and Test Methods Guide. 2023 Update.

ISO 9001:2015 Quality Management System Requirements. International Organization for Standardization, 2015.

Wang Qiang, Zhao Jun. Modern Pet Products Design and Manufacturing. Guangzhou: South China University of Technology Press, 2022.

China Hardware Products Association. Hardware Products Industry Development Report. 2024.

Chen Zhiyong. Research on the Application of Automated Manufacturing Systems in the Metal Products Industry. Manufacturing Automation, 2023, 45(3): 78-85.

_1753256285958.png)

_1754990596544.webp)