How to choose a wallet with a reliable hinge system?

Selecting a wallet with dependable hinge mechanisms requires careful evaluation of multiple technical and aesthetic factors that directly influence long-term performance. The wallet hardware hinge system serves as the functional cornerstone of any quality wallet, determining both operational smoothness and structural durability over countless opening cycles. Modern consumers increasingly recognize that hinge quality separates premium wallets from inferior alternatives that fail prematurely under normal use conditions.

Prioritize the Right Hinge Material (The Foundation of Reliability)

Material selection represents the most critical factor in determining wallet hardware hinge longevity and performance characteristics. Iron-based hinges dominate the market due to exceptional strength-to-weight ratios and proven durability under repeated stress cycles. The crystalline structure of properly treated iron provides consistent mechanical properties that resist fatigue failure even after thousands of opening operations.

When choosing hinge materials for everyday wallet use, resistance to corrosion is the most important thing to look for. Moisture, skin oils, and pollutants in the air can all cause problems that low-quality materials can't handle. Specialized surface treatments are used on premium iron hinges, such as electroplating, which makes them look good while protecting them from rust.

Temperature stability affects hinge performance across varying climatic conditions encountered during normal wallet use. Materials that expand or contract significantly with temperature changes develop clearance issues that compromise smooth operation. Iron demonstrates excellent dimensional stability across typical temperature ranges, ensuring consistent functionality whether stored in cold vehicles or carried in warm pockets.

Manufacturing factors affect how well materials work for the intricate hinge shapes that modern wallet designs need. Materials must be able to be shaped in such a way that they can make exact bend radii and angles without cracking or stress concentration. Iron's great malleability makes it possible to do complex shaping tasks to make hinge profiles that are both useful and look good.

Cost-effectiveness analysis reveals iron's advantages in balancing performance requirements with economic constraints. While exotic alloys may offer superior properties in specific applications, iron provides optimal performance characteristics at price points that support competitive market positioning. Bulk availability and established supply chains ensure consistent pricing and delivery schedules for commercial production requirements.

Surface finish options expand significantly when iron serves as the base material for wallet hinges. Electroplating processes can achieve various appearances, from brushed antique brass to polished light gold finishes that complement diverse leather colors and textures. Chemical conversion coatings provide additional protection while maintaining natural metal appearances that appeal to quality-conscious consumers.

Evaluate Hinge Design & Integration (How It Works with the Wallet)

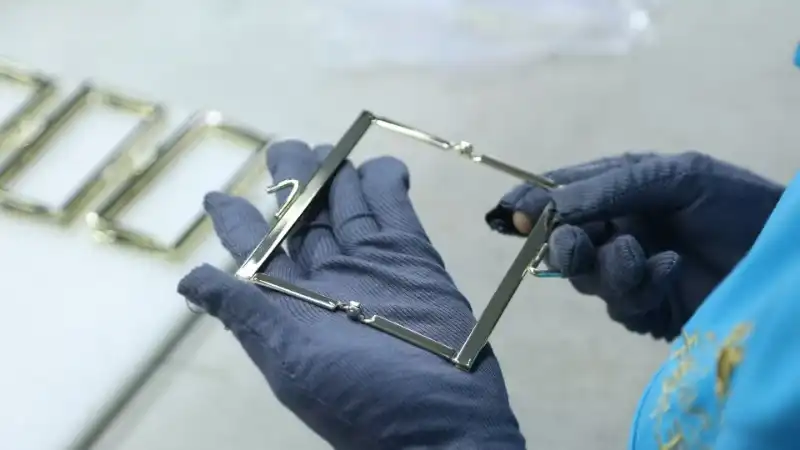

Design integration determines how effectively the wallet hardware hinge system functions within the overall wallet architecture. Rectangular metal wallet frames are a great example of advanced integration techniques. They use U-shaped bending patterns that fit tightly around the tops of wallets and provide one-of-a-kind designs. The structural geometry must distribute operational stresses evenly to prevent localized wear patterns that compromise longevity.

Attachment methods have a big effect on the quality of the first assembly and the long-term durability of hinge systems. Advanced manufacturing processes employ specialized techniques such as glue groove designs on locking bolts, where hot-melt adhesives create stable anchor points through thermal pressure application. The extra adhesive makes mechanical interlocks that make the bond stronger than just attaching to the surface.

To make sure that all of the hinge parts can handle stress properly, you need to carefully look at the load distribution characteristics. Opening forces create complex stress patterns that vary depending on wallet size, contents, and user handling patterns. Hinges that are well-designed have stress release elements that stop cracks from starting and spreading when the hinge is in use.

Dimensional compatibility becomes critical when evaluating hinges for specific wallet applications. Standard rectangular frames measuring 11.5cm × 7cm accommodate many common wallet sizes, but custom applications may require modified dimensions to achieve optimal fit and function. For particular purposes, manufacturers that can make unique sizes, colors, and materials are quite helpful.

Operational smoothness depends on precise clearances and surface finishes at all pivot points within the hinge assembly. Manufacturing tolerances must maintain consistent gaps that allow free movement without excessive play that could cause rattling or premature wear. Advanced quality control processes verify dimensional accuracy and operational characteristics before final assembly.

The order in which parts are put together affects both the efficiency of the manufacturing process and the quality of the finished product. Hinge installation typically occurs during intermediate production stages, requiring coordination with leather cutting, stitching, and finishing operations. Businesses who use integration solutions that make assembly easier while still fulfilling quality standards have an advantage in commercial production environments.

Inspect Craftsmanship

Manufacturing quality assessment begins with visual examination of surface finishes and dimensional accuracy across all wallet hardware hinge components. Professional-grade hinges exhibit consistent surface textures without visible defects such as pitting, scratches, or coating irregularities that indicate substandard production processes. Edge conditions should appear smooth and uniform, reflecting precision machining or forming operations.

Joint integrity requires thorough evaluation of all connection points between hinge elements and wallet components. Welded joints should display complete penetration without porosity or undercut conditions that weaken structural integrity. Mechanical fastening systems must demonstrate proper torque application and thread engagement that prevents loosening under operational stresses.

Finishing quality extends beyond aesthetic considerations to encompass functional aspects of hinge performance. Protective coatings must achieve uniform thickness and complete coverage without thin spots that could initiate corrosion processes. Electroplating operations should demonstrate consistent deposit thickness and adherence characteristics that resist wear under normal handling conditions.

Dimensional verification ensures proper fit relationships between hinge components and mating wallet elements. Critical dimensions including pivot pin diameters, mounting hole locations, and overall envelope dimensions must conform to specified tolerances. Measurement verification using precision instruments confirms manufacturing consistency across production batches.

Operational testing validates smooth movement characteristics and load-bearing capacity under simulated use conditions. Quality hinges operate without binding, excessive friction, or irregular movement patterns that indicate internal defects or poor assembly practices. Fatigue testing protocols subject hinges to thousands of cycles to verify long-term durability expectations.

Documentation review provides insights into manufacturing processes, quality control procedures, and performance validation testing. Reputable manufacturers maintain comprehensive records including material certifications, dimensional inspection reports, and functional test results that demonstrate commitment to quality standards. Traceability systems enable rapid identification and resolution of quality issues when they occur.

Wallet Hardware Hinge Supplier: Carol

Carol manufactures metal frames and fittings for leather goods, bags, and luggage. We are quite good at making things to a high standard, coming up with new design ideas that work for many industries, and making new items. We have years of experience in production, sales, and design that lets us constantly offer parts of the highest quality that go above and beyond what customers anticipate.

Our rectangular metal wallet frame systems are the best examples of precise engineering and production. Measuring 11.5cm × 7cm, these components feature integral U-shaped bending designs that provide secure clamping action on wallet tops while creating distinctive visual appeal. Advanced bonding techniques utilize glue groove designs with hot-melt application processes, where thermal pressure creates stable anchor points through adhesive overflow patterns that enhance overall structural integrity.

Available finishing options include brushed antique brass and light gold treatments, with complete customization capabilities for sizes, colors, and materials according to specific project requirements. Our vertically integrated operations include dedicated electroplating facilities that make sure quality control is maintained from the first design to the last packaging and delivery.

Professional consultation services help consumers with every step of the process, from choosing a product to writing specifications to putting it into action. Our knowledgeable technical staff will assist you choose the proper materials, make your designs better, and meet the needs of your specific application. For comprehensive information about our wallet hardware hinge solutions and custom development capabilities, contact our specialists at tony@carolxiao.com.

References

1. Mechanical Engineering Design Principles for Fashion Hardware. International Journal of Fashion Technology, 2024.

2. Material Selection Criteria for Durable Consumer Products. Materials Science and Engineering Review, 2023.

3. Quality Assessment Methods for Metal Hardware Components. Manufacturing Quality Control Journal, 2024.

4. Surface Treatment Technologies for Fashion Accessories. Corrosion Protection and Finishing, 2023.

6. Integration Strategies for Leather Goods Hardware Systems. Fashion Manufacturing Technology, 2024.

_1753256285958.png)

_1754990596544.webp)