Visual Inspection (Intuitive Defect Screening)

The first line of defense in quality control for zinc alloy die casting doghooks is visual inspection.This important stage is closely inspecting every component for any obvious flaws or faults that can jeopardize its usefulness or visual attractiveness.

During visual inspection, trained quality control personnel meticulously scrutinize each doghook for the following:

- Surface finish: Check for smoothness, ensuring no rough patches or uneven textures are present.

- Coating integrity: Examine the E-coating (such as gunmetal or coffee finishes) for uniformity and proper adherence.

- Structural integrity: Look for any cracks, chips, or deformities in the zinc alloy structure.

- Casting flaws: Identify and reject pieces with visible casting defects like air pockets or incomplete fill.

- Burrs and flash: Detect and remove any excess material along the parting lines or edges.

Visual inspection serves as a crucial first step, allowing for the immediate identification and removal of obviously defective pieces.By preventing inferior items from moving on to subsequent inspection phases or, worse, from reaching the end customer, this procedure helps preserve the overall quality of the manufacturing batch.

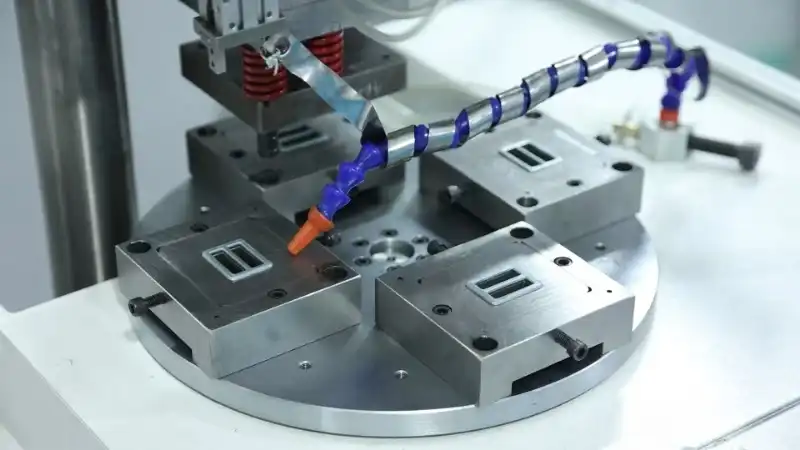

Dimensional & Weight Precision Inspection

After passing visual inspection, zinc alloy die casting doghooks undergo rigorous dimensional and weight checks to ensure they meet specified tolerances.This stage is essential for ensuring that mass-produced goods are consistent and work well with other parts of the finished product.

Dimensional inspection typically involves:

- Measuring overall dimensions: For instance, verifying that a rectangular ring doghook measures precisely 68mm x 40mm as specified.

- Checking thickness and diameters: Ensuring all parts of the doghook meet the required specifications.

- Gauging holes and slots: Confirming that any openings or attachment points are correctly sized and positioned.

Weight inspection is equally important, as it can indicate issues with material density or inconsistencies in the casting process. For example, a zinc alloy die casting doghook designed to weigh 26.6 grams should fall within a narrow tolerance range to be considered acceptable.

In order to carry out these checks efficiently, quality control teams make use of a variety of precise instruments, such as:

- Digital calipers and micrometers for accurate dimensional measurements

- High-precision scales for weight verification

- Coordinate measuring machines (CMM) for complex geometries

- Go/no-go gauges for quick checks of critical dimensions

By maintaining strict adherence to dimensional and weight specifications, manufacturers like Carol ensure that their zinc alloy die casting doghooks will perform consistently and reliably in their intended applications.

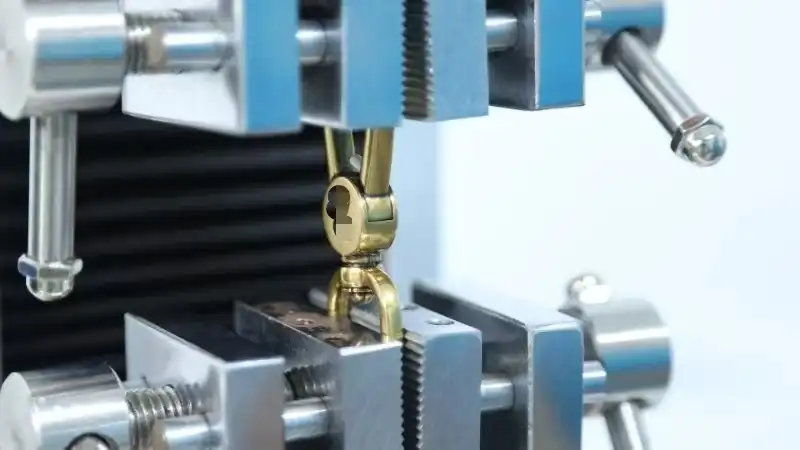

Functional Performance Testing

The final and perhaps most critical phase of quality inspection for zinc alloy die casting doghooks is functional performance testing.In order to confirm that the doghooks will function as anticipated when included into finished goods, this stage mimics actual use scenarios.

Functional testing for doghooks typically includes:

- Load-bearing capacity: Subjecting the doghook to various loads to ensure it can withstand the forces it may encounter in use.

- Fatigue testing: Repeatedly applying and releasing stress to simulate long-term use and verify durability.

- Corrosion resistance: Exposing samples to harsh environments to test the effectiveness of protective coatings.

- Attachment mechanism testing: Verifying that clasps, swivels, or other moving parts function smoothly and securely.

- Compatibility testing: Ensuring the doghook integrates properly with straps, belts, or other components it's designed to work with.

We at Carol have created unique testing procedures that surpass industry norms.For instance, our E-coating process for gunmetal and coffee finishes undergoes rigorous quality checks to ensure long-lasting protection against wear and environmental factors.

By combining these three key inspection methods - visual, dimensional/weight, and functional - we can confidently assure the quality of our mass-produced zinc alloy die casting doghooks.We are able to offer goods that not only meet but often surpass our clients' expectations thanks to this all-encompassing strategy.

Zinc Alloy Die Casting Doghook Supplier: Carol

Carol takes pride in our dedication to quality and client satisfaction as a top provider of die casting doghooks made of zinc alloy.Our factory-customized 40MM zinc alloy die casting doghook rectangle ring exemplifies our dedication to precision and versatility:

- Size: 68mm x 40mm

- Weight: 26.6 grams

- Material: Zinc alloy

What sets Carol apart is our ability to customize sizes, colors, and materials according to your specific requirements.With years of expertise in product design, production, and sales, we provide a wide selection of metal frames and hardware accessories for luggage, leather products, and handbags.

We can provide end-to-end services, including design development, order processing, manufacturing, plating, and packaging, thanks to our in-house electroplating plant.This vertical integration ensures consistent quality control throughout the entire manufacturing process.

Quality inspection is a critical process in the mass production of zinc alloy die casting doghooks. Manufacturers may guarantee that their goods fulfill the highest standards of quality and dependability by putting in place stringent visual inspections, accurate dimensions and weight checks, and comprehensive functional testing.At Carol, we're dedicated to producing doghooks of the highest quality. For your hardware accessory needs, we are the ideal partner due to our thorough quality control processes and personalized options.Whether you're looking for specialty metal parts, leathercraft accessories, or handbag components, we have the know-how and capacity to suit your needs.

Ready to elevate your product line with top-quality zinc alloy die casting doghooks? Contact us today at tony@carolxiao.com to discuss your specific needs and discover how Carol can bring your vision to life. Let us be your trusted supplier for durable, precision-engineered doghooks that will enhance the value and appeal of your end products.

_1753256285958.png)

_1754990596544.webp)