Product Design and Engineering Verification

The journey of creating a metal wallet frame begins with meticulous product design and rigorous engineering verification.The groundwork for a superior final product that satisfies both functional and aesthetic standards is laid by this important initial stage.

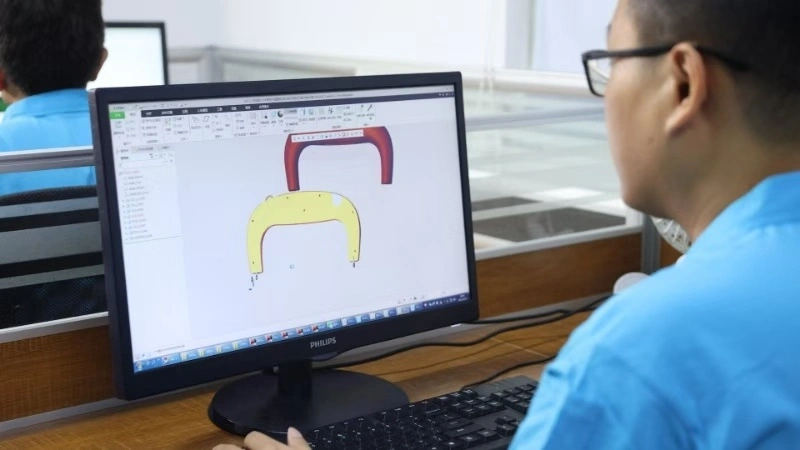

Designers begin by conceiving the frame, taking into account dimensions, form, and purpose.For instance, a rectangular metal wallet frame measuring 11.5cm x 7cm might be ideal for a standard-sized wallet.In order to visualize the finished product and spot possible problems early on, the design process entails producing intricate technical drawings and 3D models.

Once the initial design is complete, engineers step in to verify its feasibility. In order to determine whether the frame can endure normal wear and tear, they examine its structural integrity.This stage often involves computer simulations and stress tests to identify weak points or areas that need reinforcement.

The selection of materials is another essential step in this process.While iron is a common choice due to its strength and affordability, other materials may be considered based on specific requirements. The finishing process is also determined at this stage, with options like brush antique brass or light gold being popular choices for their aesthetic appeal and durability.

In engineering verification, the design's manufacturability is also evaluated. This entails determining any potential manufacturing process obstacles as well as assessing whether the suggested frame can be manufactured effectively at scale.. Any issues discovered during this phase are addressed through design iterations, ensuring a smooth transition to large-scale processing.

Large-Scale Processing

Once the design is finalized and verified, the production moves into the large-scale processing phase. This stage transforms raw materials into the basic components of the metal wallet frame through a series of sophisticated manufacturing processes.

Usually, the process starts with the purchase of premium iron sheets.These sheets are then cut to size using precision cutting tools, often employing laser or water jet technology for accuracy.The frame's characteristic rectangular shape is created by combining stamping and bending techniques to shape the cut sections.

A crucial stage in large-scale processing is surface treatment.The frames undergo thorough cleaning to remove any oils or debris from the manufacturing process.They are thereafter ready for finishing, which could entail methods like brushing to provide a textured surface.

The finishing process is where the frames truly come to life. For a brush antique brass finish, the frames are first coated with brass and then undergo a controlled oxidation process to achieve the desired antique look. Alternatively, for a light gold finish, a thin layer of gold-colored plating is applied using electroplating techniques.

Quality control measures are implemented throughout the large-scale processing phase. Automated systems and skilled technicians work in tandem to ensure each frame meets the specified dimensions and quality standards. Any pieces that don't meet these rigorous criteria are identified and removed from the production line.

Assembly, Quality Inspection, and Packaging

Assembling, carefully inspecting, and packaging are the last steps in making metal wallet frames.In order to guarantee that the final product satisfies the exacting requirements of purse manufacturers and other customers, this step is essential.

Assembly of metal wallet frames is typically a straightforward process, as most frames are designed as single pieces. However, some designs may require the attachment of additional components such as clasps or hinges. In these cases, skilled workers or precision machinery are employed to ensure proper assembly.

There is no room for error in the multi-step process of quality inspection.Each frame undergoes visual inspection to check for any cosmetic defects such as scratches, dents, or uneven finishes. The dimensions are re-verified to ensure they match the specified 11.5cm x 7cm size. Functional tests are also conducted to confirm that any moving parts operate smoothly and that the frame can withstand the stresses of regular use.

Packaging is the final step before the metal wallet frames are ready for distribution. The frames are carefully wrapped to protect their finish during transit. They may be individually wrapped in soft tissue paper and then placed in protective boxes or bags. For bulk orders, additional packaging may be used to ensure the frames arrive at their destination in perfect condition.

Traceability is preserved during this procedure.Each batch of frames is labeled with relevant information such as production date, material type, and finishing details.This helps with quality control and gives end users and purse manufacturers useful information.

Metal Wallet Frame Supplier: Carol

When it comes to sourcing high-quality metal wallet frames, Carol Metal Products Co., Ltd. stands out as a leading supplier.Carol, a reputable business based in Shenzhen, China, specializes in metal frames and hardware accessories for luggage, leather products, and handbags.

Carol sells a wide variety of items that are notable for their creative designs and rich color palette..She has years of experience in product design, sales, and production.Their metal wallet frames have gained popularity in both domestic and international markets, praised for their excellent quality and design.

One of Carol's key advantages is their in-house electroplating facility. This allows them to provide a comprehensive service, managing everything from design and order processing to production, plating, and packaging.Carol has more control over the whole manufacturing process thanks to this vertical integration, which also guarantees constant quality.

Their product line reflects Carol's dedication to quality.They make sure their goods are safe and long-lasting by prioritizing the use of eco-friendly materials in addition to aesthetic appeal.Additionally, they give their customers peace of mind by providing superior after-sales assistance for their products.

For businesses looking for customized solutions, Carol offers OEM/ODM brand processing.This implies that they are able to create metal wallet frames that meet particular specifications, such as special materials, custom colors, or unusual sizes.This implies that they are able to create metal wallet frames that meet particular specifications, such as special materials, custom colors, or unusual sizes. Their adaptability and experience make them a perfect partner for fashion designers and purse manufacturers who want to produce unique items.

A combination of artistic talent and meticulous engineering goes into creating a metal wallet frame.From the initial design phase through large-scale processing and final quality checks, each step contributes to creating a product that is both functional and aesthetically pleasing.Fashion fans and purse producers can better appreciate the artistry of these indispensable accessories by being aware of this technique.

If you're in the market for high-quality metal wallet frames or other hardware accessories for your fashion products, consider reaching out to Carol Metal Products Co., Ltd. Their rectangular metal wallet frame, measuring 11.5cm x 7cm and available in finishes like brush antique brass and light gold, could be the perfect addition to your next creation.Keep in mind that Carol provides customization choices, so you can adjust the material, color, and size to suit your requirements.

To explore Carol's range of products or discuss your custom requirements, don't hesitate to contact them at tony@carolxiao.com. With their expertise and commitment to quality, Carol can help bring your design visions to life, providing you with the perfect metal wallet frames for your purses, wallets, and other fashion accessories.

_1753256285958.png)

_1754990596544.webp)