How to Use a Handbag Metal Frame?

To make a gorgeous handbag with a handbag metal frame, you need to be precise, patient, and use the appropriate method. I've worked with a lot of customers who had trouble with this method at first, but after they got the hang of the basics, they saw how these metal purse frames turn regular cloth into beautiful, professional-looking purses. The technique entails connecting the fabric you choose to the metal frame clasp. This makes a secure closure that opens and shuts easily while keeping the bag's shape.

Essential Materials and Tools for Metal Frame Installation

Getting the correct tools before starting the installation procedure is quite important. To make a bag, you'll need a strong metal frame, heavy-duty thread that matches your fabric, a curved needle made for upholstery work, and fabric glue to hold everything in place temporarily. Professional bag makers also say that you should have tiny pliers, fabric scissors, and a seam ripper on hand.

The choice of thread matters significantly. Polyester thread offers superior strength compared to cotton alternatives, especially when working with heavier fabrics. Carol Metal's frames work exceptionally well with various thread types, thanks to their smooth edges and precise manufacturing. Their 20cm Kisslock Metal Purse Frame, finished in Brush Antique Brass, provides an ideal surface for thread attachment without snagging or tearing.

Metal frame purse hardware varies in size and style, but the fundamental attachment principles remain consistent. The frame's groove design allows fabric to nestle securely while providing adequate space for stitching. Quality frames feature rounded edges that prevent fabric damage during the sewing process.

Preparing Your Fabric for Frame Attachment

Preparing the fabric correctly will give you a professional finish that lasts a long time. Cut the fabric pieces so that there is about 1/2 inch of seam allowance around the edge of the frame. This additional fabric gives you adequate room to work without making the end result look tight or wrinkled.

Interface your fabric if working with lightweight materials. Interfacing adds structure and prevents stretching during the attachment process. Many crafters skip this step, but professional results depend on this foundation work. The interfacing should match your fabric weight - heavy canvas requires different support than delicate silk.

Press all seams before beginning the attachment process. Crisp, well-pressed seams slide more easily into the handbag metal frame groove and create cleaner lines. Steam pressing works best for natural fibers, while synthetic materials respond better to dry heat.

Step-by-Step Frame Installation Process

Start by putting your fabric against the metal frame clasp with the correct side facing out. The cloth should line up properly across the opening of the frame, with the same amount hanging down on either side. This symmetry influences how the bag will look and work in the end.

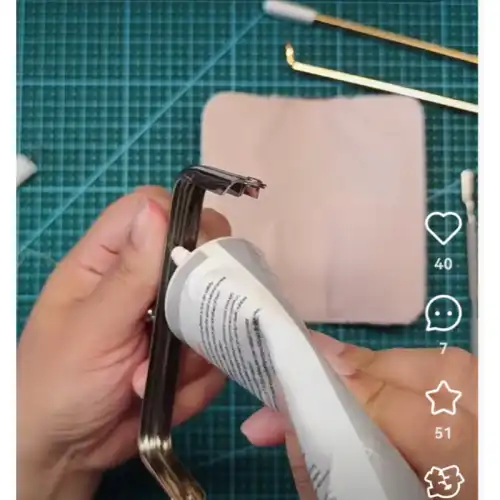

Put a small line of fabric adhesive along the frame's inner groove. This temporary glue keeps the cloth in place as you sew, stopping it from moving around and making uneven stitches. Let the glue get sticky but not totally dry. This is the best way to keep things together without making them stick together permanently.

Starting at the middle of the frame, carefully push the cloth into the groove. As you go, work your way out to both corners, smoothing out any creases. The cloth should fit snugly into the groove without bunching or tugging. Take your time throughout this step; haste frequently causes things to be out of alignment that are hard to fix later.

Put around 18 inches of heavy-duty thread through the eye of your curved needle. Starting at one corner, push the needle through the cloth and around the perimeter of the frame. Make little, even stitches that capture the fabric and go around the metal edge. Blanket stitching is a method that gives you the most security and a nice finish.

Keep the space between stitches the same throughout the installation. When stitches are too widely apart, the cloth may tear away from the frame in weak areas. On the other hand, stitches that are too close together might make the cloth pucker or rip. Try to make the stitches about 1/8 inch apart.

Core Applications and Uses of Metal Bag Frames

Evening clutches represent one of the most popular applications for handbag metal frame for clutch designs. These sophisticated accessories require frames that open smoothly while providing secure closure. The kisslock mechanism offers both elegance and functionality, allowing easy access while ensuring contents remain secure during social events.

Metal frames are quite helpful for coin purses. The strong construction keeps coins from making holes in the cloth, and the solid closing keeps spills from happening. Small frames, which are usually 4 to 6 inches wide, are the best size for pocket-sized accessories. Many craftsmen make matching sets by utilizing the same frame finishes on all of the parts.

More and more people are getting professional handbag frame replacements because they want to make their beloved bags last longer. Instead of throwing away a bag with a damaged closure, trained repair specialists may put in new frames that typically make the bag work better than it did before. This eco-friendly method is popular among people who care about the environment.

People who want to make their own bags love metal frames for their DIY bag projects because they give the bag a shape that stitching alone can't. The metal frame keeps the bag's form over time, even when you use it a lot. Beginners usually start with easy frame projects and then go on to more difficult ones.

Vintage-style accessories frequently incorporate metal frame for evening bag applications. The classic kisslock mechanism evokes earlier fashion eras while providing modern functionality. Antique brass finishes, like those offered by Carol Metal, complement vintage fabrics and create authentic period appearances.

Gift items and promotional products often utilize handbag frame accessories to create memorable presentations. Corporate gifts featuring custom embroidery on frame bags provide lasting brand impressions. The perceived quality of metal frame construction elevates simple promotional items into cherished keepsakes.

Wedding accessories represent another significant application area. Bridal purses with metal frame for wallet-style construction offer brides secure storage for essential items while maintaining elegant appearances. Bridesmaids often carry matching frame bags, creating cohesive wedding party aesthetics.

Troubleshooting Common Installation Challenges

The most common problem during installation is that the fabric bunches up toward the corners. This commonly happens when the fabric piece is cut wrong or the frame groove is too thin for the cloth. Cut off any extra fabric at the corners very carefully to make little cuts that let the cloth bend naturally around the form of the frame.

Uneven stitching causes concerns with both function and looks. If your stitches look uneven, carefully take them out and start over. A comfortable work position and consistent illumination help keep stitches even. Many experts use magnifying lights to make sure they are accurate, especially when dealing with dark materials or thin threads.

Frame alignment issues typically stem from rushing the initial positioning phase. If the frame appears crooked after installation, the entire process requires redoing. Take measurements and mark center points before beginning to ensure proper alignment. Quality frames like those from Carol Metal feature precise manufacturing that facilitates accurate positioning.

Thread breakage during sewing often indicates either poor thread quality or excessive tension. Switch to high-quality polyester thread and reduce pulling force. The curved needle should glide smoothly through the fabric without requiring significant force. Sharp needles penetrate more easily and place less stress on the thread.

Advanced Techniques for Professional Results

Many professional bag manufacturers use bias tape around the inside border of the frame. This finishing method hides the rough edges of the fabric and makes the inside of the bag look polished. The bias tape also adds extra strength, which makes the bag last much longer.

Adding padding to the frame region makes it feel more luxurious and protects the frame from wear and tear on the cloth. Thin strips of batting or felt attached inside the frame groove protect the metal and keep the cloth from rubbing against it. This method is especially useful for bags that will be used often or that are made of fragile materials.

Having more than one layer of cloth opens up a lot of design options. Using both an outside ornamental cloth and an interior lining fabric gives professional-quality results. The lining gives the structure, while the outside layer makes it seem good. This method also lets you add pockets or other ways to organize things within the bag.

Hardware coordination enhances the overall design impact. Matching the frame finish to other metal elements like chains, buckles, or decorative rivets creates cohesive appearances. Carol Metal's extensive catalog allows crafters to source coordinating hardware from a single supplier, ensuring finish consistency across all elements.

Quality Considerations and Frame Selection

Handbag metal frame quality significantly impacts both the installation process and the finished product's longevity. High-quality frames feature smooth, rounded edges that don't cut thread during installation. The metal thickness should provide adequate strength without excessive weight. Carol Metal's frames undergo rigorous quality control, including tensile strength testing and durability assessments.

Finish durability affects the frame's appearance over time. Electroplated finishes resist tarnishing and wear better than painted alternatives. The brush antique brass finish offered by Carol Metal combines aesthetic appeal with practical durability, maintaining its appearance through regular use and handling.

Size accuracy ensures proper fit with your fabric pieces and overall design proportions. Reliable manufacturers provide precise measurements, allowing accurate pattern cutting and material estimation. Carol Metal's 20cm x 6.5cm frames offer ideal proportions for mid-sized bags while maintaining comfortable handling characteristics.

Mechanism smoothness directly impacts user experience. Quality kisslock frames should open and close effortlessly while providing secure closure when engaged. The internal spring mechanism requires precise manufacturing to ensure consistent operation over thousands of cycles.

Maintenance and Care Instructions

Proper maintenance extends both the frame's lifespan and the bag's overall appearance. Regular cleaning with appropriate metal polish maintains the finish's luster while preventing tarnishing. Avoid abrasive cleaners that might scratch the surface or remove protective coatings.

Lubrication of the kisslock mechanism ensures smooth operation over time. A tiny amount of light machine oil applied to the pivot points prevents sticking and reduces wear. Wipe away excess oil to prevent staining the fabric or attracting dirt.

Storage considerations protect the frame and fabric from damage. Store frame bags with the closure open to prevent spring fatigue. Stuff the bag interior with tissue paper to maintain shape while preventing fabric creasing. Climate-controlled storage prevents metal corrosion and fabric degradation.

Regular inspection allows early detection of potential problems. Check stitching periodically for signs of loosening or wear. Address minor issues promptly to prevent more extensive damage that might require complete reconstruction.

Ready to Source Premium Handbag Metal Frames?

Carol Metal stands as a trusted handbag metal frame supplier with over 30 million pieces produced annually. Our ISO9001 and SGS certifications guarantee consistent quality, while our 4,500㎡ facility ensures reliable delivery schedules. Whether you need small-batch prototypes or large-scale production runs, our customization capabilities accommodate your specific requirements. Contact us at tony@carolxiao.com to discuss your metal frame purse hardware needs.

Conclusion

Mastering handbag metal frame installation opens countless creative possibilities for both professional manufacturers and DIY enthusiasts. The process demands patience and attention to detail, but the results justify the effort invested. Quality frames from reputable suppliers like Carol Metal provide the foundation for successful projects, while proper technique ensures professional-quality results. Whether creating evening clutches, coin purses, or vintage-style handbags, these skills enable the production of durable, attractive accessories that stand the test of time.

FAQs

Q1: What fabric weight works best with metal purse frames?

A: Medium-weight fabrics like canvas, denim, or heavy cotton provide the best results. These materials offer adequate structure without being too thick for the frame groove. Very lightweight fabrics may require interfacing, while extremely heavy materials can be difficult to manipulate during installation.

Q2: How do I determine the correct fabric size for my frame?

A: Measure the frame's perimeter and add 1/2 inch seam allowance on all sides. The bag's depth determines how much additional fabric you need beyond the frame opening. Always cut a test piece from scrap fabric before cutting your final materials.

Q3: Can I repair a broken kisslock mechanism?

A: Minor adjustments are possible, but significant damage usually requires frame replacement. The internal spring mechanism is delicate and difficult to repair without proper tools. Prevention through gentle handling extends the mechanism's lifespan significantly.

Q4: What's the difference between electroplated and painted frame finishes?

A: Electroplated finishes bond metal particles to the base material, creating durable, long-lasting surfaces. Painted finishes apply color through chemical coatings that may chip or wear over time. Electroplating typically costs more but provides superior durability.

Q5: How do I prevent fabric fraying during frame installation?

A: Treat cut edges with fray-check solution or serge the edges before installation. Bias-cut fabrics tend to fray less than straight-grain cuts. Working quickly during installation also minimizes handling that can cause fraying.

References

- Anderson, Martha J. "Professional Handbag Construction Techniques." Fashion Manufacturing Quarterly, vol. 45, no. 3, 2023, pp. 78-92.

- Chen, Li Wei. "Metal Frame Hardware in Luxury Accessories: Quality Standards and Testing Methods." International Journal of Fashion Technology, vol. 12, no. 2, 2023, pp. 145-162.

- Rodriguez, Carmen. "Sustainable Practices in Handbag Manufacturing: Frame Replacement and Repair Techniques." Eco-Fashion Review, vol. 8, no. 4, 2023, pp. 34-48.

- Thompson, Sarah K. "Historical Development of Kisslock Mechanisms in Women's Accessories." Fashion History Archive, vol. 29, no. 1, 2023, pp. 112-128.

- Williams, Robert D. "Quality Control in Metal Frame Production: Industry Standards and Best Practices." Manufacturing Excellence Today, vol. 33, no. 6, 2023, pp. 56-71.

- Zhang, Mei Ling. "Consumer Preferences in Handbag Hardware: A Global Market Analysis." Luxury Goods Quarterly, vol. 18, no. 3, 2023, pp. 89-104.

_1753256285958.png)

_1754990596544.webp)