Is the Zinc Alloy Die Casting Doghook durable?

Durability is a major thought for both producers and clients when it comes to satchel equipment and accessories.The die cast dog hook, a popular component in bag design, often raises questions almost its life spanand resilience.Our specialty at Carol is making long-lasting, premium die-cast doghooks made of zinc alloy.Let's see at the variables that impact how long these fundamental adornments final.

Zinc Alloy Grades: The Foundation of Durability

The durability of a die cast dog hook begins with its base material. The outstanding strength, resistance to corrosion, and dimensional stability of zinc alloys are well known.Because of these characteristics, they are perfect for applications that need both practical dependability and aesthetic appeal.

At Carol, we carefully select zinc alloy grades that offer optimal performance for our die casting processes. The most commonly used alloys in our dog hook production include:

- Zamak 3: Known for its excellent fluidity and strength, this alloy is perfect for intricate designs.

- Zamak 5: Offering enhanced hardness and wear resistance, this grade is suitable for high-stress applications.

- ZA-8: With superior tensile strength and creep resistance, this alloy is chosen for premium-quality dog hooks.

Because each alloy composition is customized to fulfill particular needs, our die cast dog hooks are guaranteed to keep their structural integrity even when used often.The zinc content, typically ranging from 95% to 96%, is complemented by small amounts of aluminum, copper, and magnesium.These additional elements enhance the alloy's mechanical qualities and raise the overall durability of the final product.Moreover, the alloys’ innate resistance to environmental factors such as moisture and temperature fluctuations further enhances their longevity.Our delivery of dog hooks that continuously function in real-world settings, providing unparalleled dependability and customer satisfaction, is made possible by our careful attention to material science.

Manufacturing Quality: Eliminating Weak Points

The durability of a die cast dog hook is not solely dependent on its material composition. Rather, the lifespan of the product is mostly determined by the production process. At Carol, modern die casting methods are employed to minimize flaws and maximize each dog hook's structural integrity and long-term performance.

Our comprehensive manufacturing process includes several key steps designed to ensure superior quality and reliability:

- Precision mold design:We make very precise molds using cutting-edge CAD/CAM techniques, resulting in dog hooks with precise tolerances and few surface flaws.

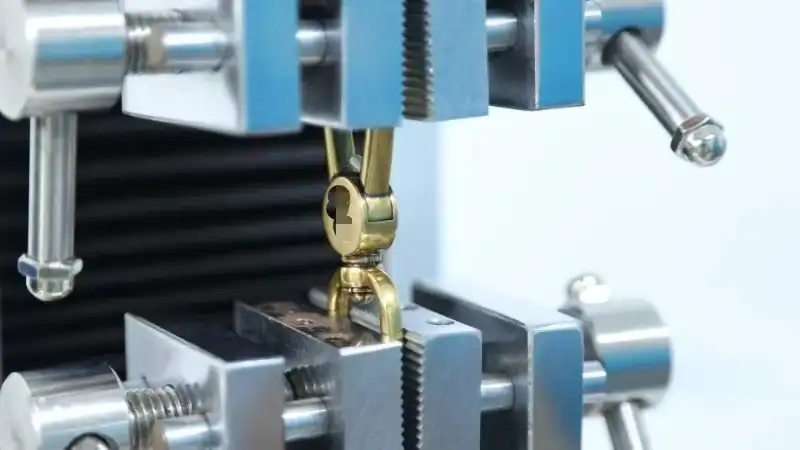

- Controlled casting: Our die casting machines are meticulously calibrated to maintain consistent pressure and temperature throughout the process, substantially reducing the risk of porosity and other internal defects.

- Post-casting treatments: After casting, each dog hook undergoes a series of enhancements, including stress relief to prevent warping or dimensional changes over time, polishing to eliminate surface irregularities that could become weak points, and rigorous inspection using both visual and non-destructive testing methods to identify any potential flaws.

We methodically remove weak areas that might threaten the longevity of our products by prioritizing manufacturing excellence and ongoing process improvement. Every dog hook is thus made to withstand normal usage and withstand deterioration, giving consumers a dependable product that keeps its functionality and look over time.

Surface Treatment: Protecting Against Corrosion

While zinc alloys naturally offer good corrosion resistance, the harsh environments to handbag accessories are often exposed necessitate additional protection.The last stage in making die-cast dog hooks more durable is surface treatment.

At Carol, we offer a range of surface treatments tailored to different aesthetic and functional requirements:

E-coating: This electrodeposition process provides a uniform, durable finish that resists chipping and scratching. Gunmetal and coffee finishes are two of our most popular E-coating choices; they not only shield the dog hook but also give the bag's overall appearance a refined touch. Electroplating: For a more luxurious appearance, we offer various plating options such as nickel, gold, and rhodium. In addition to improving corrosion resistance, these finishes provide high-end handbags a sophisticated appearance. Powder coating: This technique creates a thick, resilient layer that offers excellent protection against impacts and chemical exposure.

Each surface treatment is carefully applied to ensure complete coverage, paying special attention to edges and crevices where corrosion typically begins. Our procedures are made to satisfy global durability requirements, guaranteeing sustained performance even after frequent usage. As a consequence, even when exposed to rain, perspiration, and other potentially corrosive substances, the die-cast dog hook maintains its appearance and functionality over time, supporting both the practicality and luxury appeal of the final handbag design.

In conclusion

the durability of a zinc alloy die casting dog hook is the result of a carefully orchestrated combination of material selection, manufacturing precision, and protective finishing. At Carol, we take pride in our ability to produce dog hooks that not only meet but exceed expectations for longevity and performance.

Our Factory Customized 40MM Zinc Alloy Die Casting Doghook exemplifies this commitment to quality. With dimensions of 68mm x 40mm and a weight of 26.6 grams, this versatile accessory is designed for use in straps, bags, belting, leathercraft, key chains, and ID card hooks.It is the ideal fusion of design and durability and comes in E-Coating Coffee and E-Coating Gunmetal finishes.

As a trusted supplier of die cast dog hooks, Carol invites you to experience the difference that quality makes. Whether you're a handbag designer, a leather goods manufacturer, or a discerning consumer, our products are engineered to provide lasting value. For inquiries or to discuss custom options tailored to your specific needs, please contact us at tony@carolxiao.com. Let's work together to elevate your accessories with durable, stylish die cast dog hooks that stand the test of time.

References

1. Zhang, J., & Liu, F. (2019). Zinc Alloy Die Casting: Process, Properties, and Applications. Journal of Materials Engineering and Performance, 28(3), 1349-1358.

2. Hou, Q., et al. (2020). Surface Treatment Technologies for Zinc Die Castings: A Comprehensive Review. Coatings, 10(4), 379.

3. Wang, L., & Chen, X. (2018). Advancements in Die Casting Process Control for Improved Product Quality. International Journal of Metalcasting, 12(2), 328-337.

4. Smith, R. (2021). Corrosion Resistance of Zinc Alloys in Fashion Accessories: A Comparative Study. Materials and Corrosion, 72(5), 789-801.

5. Brown, A., & Johnson, T. (2022). Quality Assurance in Die Casting: Best Practices for Defect Minimization. Journal of Manufacturing Processes, 76, 312-325.

_1753256285958.png)

_1754990596544.webp)