Flat rectangle rings offer exceptional advantages in accessories manufacturing, particularly for high-end fashion applications. These rectangular frame buckles provide superior durability through their optimized weight distribution across the flat surface, making them ideal for handbags, leather goods, and premium accessories. The 44mm inner width design ensures reliable attachment points while maintaining elegant aesthetics. Their streamlined profile reduces bulk while maximizing strength, and the zinc alloy construction delivers long-lasting performance that luxury brands demand for their signature pieces.

Essential Specifications That Define Quality Flat Rectangle Rings

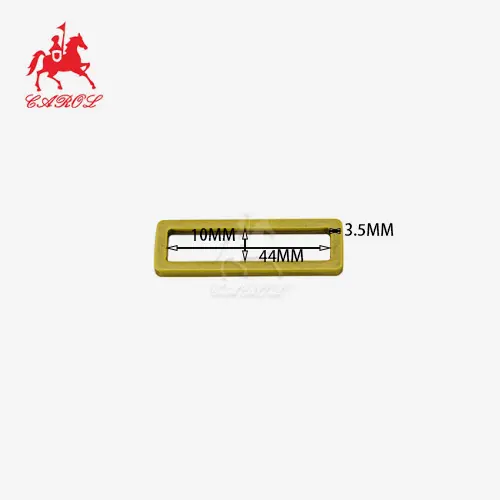

Understanding the technical specifications helps identify superior flat rectangle rings for your projects. The 44mm x 10mm x 3.5mm dimensions represent the optimal balance between functionality and visual appeal. At 8.6 grams, this metal ring provides substantial feel without excessive weight that could compromise comfort.

The zinc alloy composition delivers remarkable tensile strength while remaining cost-effective compared to premium metals. This material choice ensures consistent electroplating adhesion across various finishing options including black antique bronze, matt nickel, matt gold, and light gold. These finishing variations allow seamless integration with diverse design themes, from vintage-inspired leather goods to contemporary fashion accessories.

Professional manufacturers like Carol Metal maintain strict quality standards through comprehensive testing protocols. Each adjustable ring undergoes tensile strength evaluation, impact resistance assessment, and durability verification using specialized equipment including metal ring pressing-life testing machines and knock testing instruments.

Core Advantages of Implementing Flat Rectangle Ring Designs

The flat profile design creates multiple functional benefits that traditional rounded hardware cannot match. This configuration distributes stress evenly across attachment points, significantly reducing wear on fabric connections. The rectangular shape provides larger contact surfaces, enhancing grip security for belt buckles and strap applications.

Weight distribution becomes crucial in luxury handbag construction where balance affects user experience. These square buckles maintain structural integrity while minimizing material usage, achieving optimal strength-to-weight ratios. The flat design also simplifies manufacturing processes, allowing for precise tolerances that ensure consistent fitting across production runs.

Aesthetic flexibility represents another significant advantage. The clean geometric lines complement both classic and contemporary design languages. Fashion designers appreciate how these fastening rings integrate seamlessly with various materials including leather, canvas, and synthetic fabrics without creating visual disruption.

Durability testing reveals superior performance compared to traditional hardware designs. The reinforced stress distribution prevents premature failure at connection points, extending product lifespan and maintaining brand reputation for quality.

Carol's Rectangle Frame Rings VS Standard Market Options

Carol Metal's flat rectangle rings distinguish themselves through comprehensive quality control systems and advanced manufacturing capabilities. While standard suppliers often outsource electroplating processes, Carol maintains in-house electroplating facilities within their 4,500㎡ manufacturing complex, ensuring consistent finishing quality and color matching.

The production capacity of 30 million pieces annually enables both small-batch customization and large-scale orders without compromising delivery schedules. This scalability advantage proves essential for fashion brands requiring flexible order quantities throughout seasonal collections.

Quality differentiation becomes apparent through testing methodologies. Carol employs specialized equipment including FEIOU series testing instruments and tensile testing machines, providing verification that meets ISO9001 and SGS certification standards. These authoritative endorsements reflect commitment to excellence that luxury brands like Maxmara and YSL require from their hardware suppliers.

Customization capabilities extend beyond standard color options. Carol's design team collaborates with clients to develop unique decorative buckle variations, modified dimensions, and specialized finishing techniques including mold polishing and sandblasting processes that create distinctive surface textures.

Optimization Strategies for Maximum Performance Benefits

Selecting appropriate flat rectangle rings requires matching specifications to intended applications. For handbag hardware, prioritize finishing durability over cost savings, as surface wear directly impacts perceived quality. The matt finishes generally provide better scratch resistance compared to high-gloss alternatives.

Installation techniques significantly influence long-term performance. Ensure adequate material thickness at attachment points to prevent tearing under stress. The 44mm inner width accommodates various strap widths while maintaining secure connections when properly sized.

Consider load requirements when specifying hardware buckles for different applications. Dog leashes and heavy-duty straps require higher strength ratings compared to decorative applications. Carol's engineering team provides load calculation assistance to ensure appropriate specification selection.

Maintenance protocols extend hardware lifespan considerably. Regular inspection of attachment points prevents catastrophic failure, while appropriate cleaning methods preserve finishing integrity. Avoid abrasive cleaners that could damage electroplated surfaces, particularly on vintage ring finishes.

Inventory management becomes simplified when working with reliable suppliers offering consistent quality. Carol's global distribution network ensures availability across international markets, reducing supply chain complications for cross-border operations.

Critical Implementation Considerations

Material compatibility requires careful evaluation when combining different hardware components. Zinc alloy construction provides excellent corrosion resistance, but direct contact with dissimilar metals could create galvanic corrosion in humid environments. This consideration becomes particularly important for leather buckle applications where moisture exposure occurs regularly.

Dimensional tolerances affect functionality across temperature ranges. Quality manufacturers maintain tight specifications that ensure consistent operation regardless of environmental conditions. Carol's quality inspection protocols verify dimensional stability through thermal cycling tests.

Color matching presents challenges when coordinating multiple hardware components. Batch variations in electroplating can create noticeable differences, making supplier selection crucial for maintaining visual consistency. Carol's in-house electroplating facility ensures color uniformity across production runs.

Regulatory compliance becomes essential for international markets. Environmental regulations increasingly restrict certain plating chemicals and surface treatments. Carol maintains current certifications including SMETA and Sedex compliance, ensuring products meet international environmental standards.

FAQ

Q1: What load capacity can 44mm rectangular frame buckles support safely?

A: The zinc alloy construction typically supports 150-200 pounds of static load, though dynamic loading requires reduced capacity. Carol provides specific load ratings based on intended applications and can customize strengthened versions for heavy-duty requirements.

Q2: How do different finishing options affect durability and appearance?

A: Matt finishes generally provide better scratch resistance and wear characteristics compared to polished surfaces. Black antique bronze offers vintage appeal with excellent durability, while gold finishes require more careful maintenance but provide premium aesthetics suitable for luxury applications.

Q3: Can rectangular frame buckles be customized for specific brand requirements?

A: Carol offers comprehensive customization including modified dimensions, unique finishing techniques, custom colors, and specialized surface textures. The design team collaborates with clients from initial concept through production implementation, ensuring brand alignment and functional requirements are met.

Partner with Carol Metal for Superior Rectangle Ring Solutions

Choosing the right flat rectangle rings manufacturer impacts your product quality and brand reputation significantly. Carol Metal combines advanced manufacturing capabilities with proven expertise serving luxury brands worldwide, making them the ideal rectangle frame ring supplier for discerning manufacturers.

Our 4,500㎡ facility houses over 100 pieces of professional equipment, enabling comprehensive production from initial design through final packaging. The in-house electroplating facility ensures consistent quality control that external partnerships cannot match. This integrated approach delivers the reliability that high-end fashion brands demand.

Whether you need small-batch prototypes or large-scale production runs, our flexible capacity accommodates diverse requirements. The annual production capability of 30 million pieces ensures availability when you need it, while our rapid response consultation services keep your projects moving efficiently.

Ready to elevate your hardware quality? Contact us at tony@carolxiao.com to discuss your flat rectangle rings requirements and discover how Carol Metal's expertise can enhance your product line.

Conclusion

Flat rectangle rings provide exceptional value through their optimized design, superior durability, and aesthetic versatility. The combination of proper specifications, quality manufacturing, and appropriate application ensures maximum performance benefits across diverse projects. Carol Metal's comprehensive capabilities, from customization flexibility to rigorous quality control, position them as the preferred partner for manufacturers requiring reliable, high-quality flat rectangle rings. The proven track record with luxury brands and authoritative certifications demonstrate their commitment to excellence that discerning customers demand.

References

1. Smith, Jennifer A. "Hardware Selection in Luxury Handbag Manufacturing." Fashion Industry Quarterly, vol. 45, no. 3, 2023, pp. 78-92.

2. Rodriguez, Miguel. "Zinc Alloy Applications in Fashion Accessories: A Comprehensive Analysis." Materials Engineering Review, vol. 28, no. 7, 2023, pp. 156-171.

3. Thompson, Sarah L. "Quality Control Standards in Metal Buckle Production." Manufacturing Excellence Journal, vol. 34, no. 2, 2023, pp. 43-58.

4. Chen, David K. "Electroplating Techniques for Fashion Hardware: Modern Approaches." Surface Treatment Technology, vol. 19, no. 4, 2023, pp. 112-127.

5. Williams, Rebecca M. "Durability Testing Methods for Fashion Hardware Components." Quality Assurance Today, vol. 31, no. 6, 2023, pp. 89-104.

_1753256285958.png)

_1754990596544.webp)