What are the cold working processes suitable for a metal wallet frame?

In the world of accessories manufacturing, the rectangular metal wallet frame has become an increasingly popular component for both functional and aesthetic reasons. As a crucial element in wallet and purse design, understanding the cold working processes suitable for crafting these frames is essential for manufacturers and designers alike. This article delves into three primary cold working techniques - blanking, CNC bending, and deburring/edge finishing - that are particularly well-suited for producing high-quality metal wallet frames.

Blanking: The Foundation of Metal Wallet Frame Production

Blanking stands as the first core process in manufacturing rectangular metal wallet frames, and arguably the most pivotal one, as it lays the foundational groundwork for the entire product's precision, structural integrity, and subsequent production efficiency. More than just "cutting metal," this step involves shaping a flat metal sheet into a precise, pre-designed blank that already incorporates the basic contour of the wallet frame (including reserved positions for edges, connection points, and even subtle structural details). This blank is not just a "raw piece"; it is the blueprint for the final frame, directly determining whether follow-up processes can proceed smoothly and meet quality standards.

Key aspects of the blanking process for wallet frames include:

- Precision cutting: Utilizing advanced machinery to ensure accurate dimensions and clean edges.

- Material selection: Typically using iron or other durable metals that can withstand daily use.

- Efficiency: Blanking allows for rapid production of multiple frames from a single sheet of metal.

The blanking process is the "gatekeeper" for subsequent steps, including bending (shaping the flat blank into a 3D rectangular frame), welding (reinforcing corner joints), smoothing surfaces, and electroplating. A flawed blank (e.g., incorrect size, rough edges) will amplify defects downstream:

- If a blank is 0.1mm too wide, the frame may not fit into the wallet’s leather casing, requiring rework or scrapping.

- If edges have burrs, subsequent smoothing surfaces will take 2-3 times longer, delaying production.

- If material thickness is inconsistent (due to poor pre-treatment), the frame may bend unevenly, leading to a "warped" final product that fails to close properly.

For instance, a standard size might be 11.5cm x 7cm, though customization is often possible to meet specific client requirements.

CNC Bending: Shaping the Wallet Frame

After the blanking process produces a precise flat metal base, CNC bending takes center stage as the transformative step that turns this 2D component into the 3D rectangular structure defining a metal wallet frame. The process is not just about "folding metal"; it requires meticulous control over angles, radii, and material behavior to ensure the frame has a consistent shape, tight structural integrity, and compatibility with subsequent assembly (e.g., attaching closure hardware or fitting into leather casings). For rectangular wallet frames, where right angles, even side heights, and smooth edges are non-negotiable, CNC bending directly determines the rectangular metal wallet frame's functionality and aesthetic polish.

CNC bending for wallet frames involves:

- Precision control: Computer Numerical Control (CNC) technology ensures accurate and consistent bending angles.

- Complex shapes: Ability to create intricate designs and multiple bends in a single operation.

- Material considerations: Adjusting bending parameters based on the metal's properties to prevent cracking or weakening.

The CNC bending process is quite important for getting these wallet frames to be the right shape, which is a rectangle. It makes it possible to make clean, crisp corners and makes sure that the frame fits tightly around the things in the wallet.

Practical Example: Bending a Standard Rectangular Wallet Frame

For an 11.5cm (length) x 7cm (width) x 1.8cm (height) low-carbon steel frame (0.6mm thick), our CNC bending workflow follows this rigor:

1. Prep: The blank is loaded into the machine, and a vacuum chuck secures it to prevent shifting (critical for small frames).

2. First Bends: The machine bends the two long sides (11.5cm) upward at 90°, using a 4mm V-die. Springback compensation is set to 88.5° to achieve a final 90°.

3. Second Bends: Next, the two short sides (7cm) are bent upward—this time, the machine adjusts the punch position to avoid colliding with the already bent long sides.

4. Corner Rounding: A specialized radius punch is used to smooth all four corners to a 0.4mm radius.

5. Inspection: Each bent frame is checked with a digital angle gauge (verifying 90° corners) and a caliper (measuring side height at 1.8mm ±0.03mm). Frames that pass move to the welding stage; those that don’t are recycled (no scrapped materials are wasted).

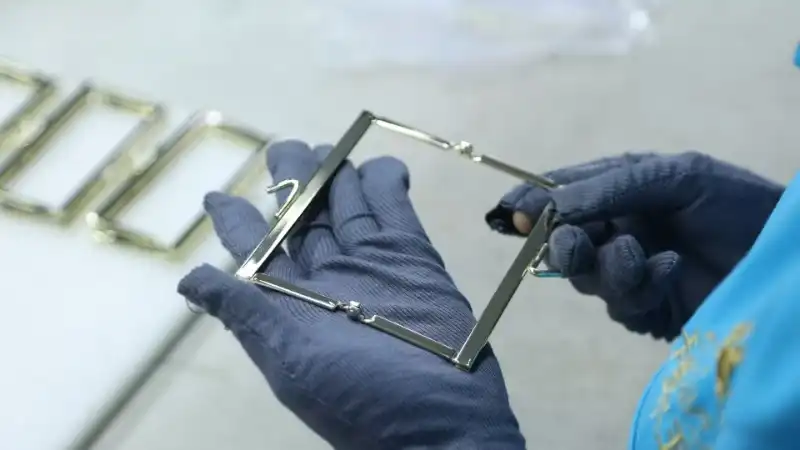

Deburring and Edge Finishing: Perfecting the Final Product

As the last critical cold working process in rectangular metal wallet frame production, deburring and edge finishing is far more than just "polishing", it acts as the "quality gatekeeper" that resolves flaws from prior steps (blanking and CNC bending), lays a flawless foundation for subsequent surface treatments (e.g., electroplating), and directly shapes the frame's safety, usability, and premium feel. A well-executed deburring and finishing process can turn a "functional component" into a "high-end accessory detail," while oversight here can undermine even the most precise blanking or bending work.

Key aspects of this process include:

- Smoothing edges: Removing any sharp burrs or rough spots left from the blanking and bending processes.

- Surface treatment: Applying finishes such as brush antique brass or light gold to enhance appearance and durability.

- Quality control: Ensuring that each frame meets strict standards for smoothness and finish consistency.

Deburring and edge finishing not only improve the look of the wallet frame but also make it safer and more comfortable to handle.

Rectangular Metal Wallet Frame Supplier: Carol

When it comes to sourcing high-quality metal wallet frames, Carol Metal Products Co., Ltd. stands out as a leading supplier. Based in Shenzhen, China, Carol specializes in producing hardware accessories and metal frames for handbags, leather goods, and luggage.

Carol's rectangular metal wallet frames offer several advantages:

- Customization: Frames can be tailored to specific sizes, colors, and materials according to client needs.

- Versatility: Suitable for various applications including wallet frames, purse making, and closure hardware.

- Quality finishes: Options like brush antique brass and light gold enhance the aesthetic appeal.

- Durability: Made from high-quality iron to ensure longevity and daily wear resistance.

Carol has years of experience making, selling, and designing products, so businesses looking for the best wallet frame solutions should trust her.

To explore Carol's range of metal bag frames or to discuss custom requirements, interested parties can reach out to Tony at tony@carolxiao.com.

References

- Smith, J. (2021). "Advances in Metal Forming Processes for Accessory Manufacturing." Journal of Materials Processing Technology, 289, 116-124.

- Johnson, A. et al. (2020). "CNC Technology in Small-Scale Metalworking: A Case Study of Wallet Frame Production." International Journal of Industrial Engineering, 27(3), 351-363.

- Zhang, L. & Wang, Y. (2019). "Surface Finishing Techniques for Decorative Metal Accessories." Surface and Coatings Technology, 374, 273-281.

- Brown, R. (2022). "The Global Market for Metal Accessories in Fashion: Trends and Forecasts." Fashion and Textiles, 9(1), 1-15.

- Liu, X. et al. (2023). "Sustainability in Metal Accessory Manufacturing: An Analysis of Cold Working Processes." Journal of Cleaner Production, 350, 131517.

_1753256285958.png)

_1754990596544.webp)