Yes, die-cast and forged lobster-clasp dog hooks have very different strength levels. Because the grain structure is compressed, forged hooks have better tensile strength and load-bearing capacity. Die-cast hooks, on the other hand, are more cost-effective for lighter uses. Procurement professionals need to understand these differences so they can choose the right Lobster Claps Dog Hook solutions for a range of hardware settings that need certain levels of durability and can't spend too much.

Understanding Lobster-Clasp Dog Hooks: Types and Manufacturing Methods

Lobster-clasp dog hooks are important spring-loaded fasteners that make sure pet leashes, collars, and other things stay connected. These useful pieces of hardware have unique curved shapes with gates that work like springs. This lets you attach and detach them quickly. These days, businesses that make keychains, handbags, purses, and ID card holders are also considered "pet products."

The Die-Casting Method of Making

Die-casting is the process of pouring metal that is very hot and liquid into precisely shaped molds made of steel under high pressure. This way of making things works great for producing shapes with lots of detail and smooth surfaces. This makes it perfect for situations where you need to make a lot of the same thing. The process lets manufacturers keep the costs low for large orders while making sure that the dimensions are always correct. Carol's advanced die-casting tools can make zinc alloy hooks that are 46mm x 11mm and 8.4 grams each. The hooks can have either a brush antique brass or nickel finish.

The Making of Forging

Using hammering, pressing, or rolling actions, forging shapes heated metal blocks by using forces that push them together. This process makes the molecular alignment and grain flow patterns better, which makes the mechanical properties much better. The compressive forces get rid of the holes and empty spaces that are common in cast products. This makes the metal structures denser, which improves their fatigue resistance and impact strength.

Comparative Analysis of Strength and Durability

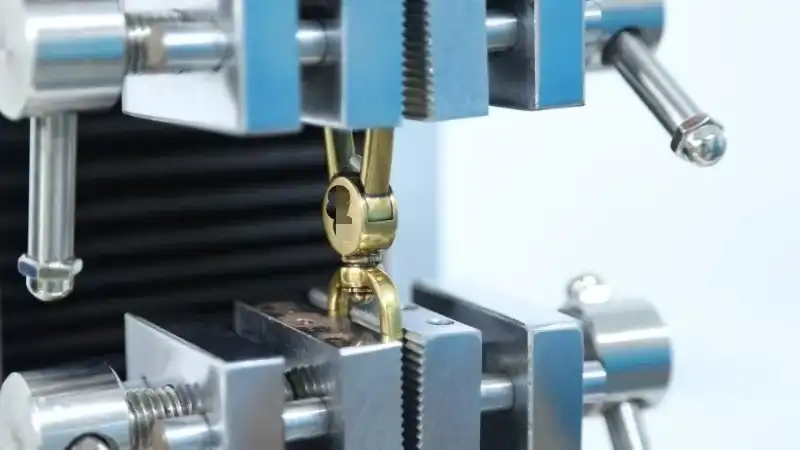

Mechanical testing shows that there are big differences in performance between different ways of making hooks. In many strength categories, forged hooks are always better than hooks made with die casting. These differences affect how people choose products for uses that need certain levels of durability and load-bearing capacity.

Tensile Strength Test

Lobster claps dog hooks with a forged lobster clasp usually have 20% to 30% higher tensile strength than similar die-cast hooks. Industry tests show that hooks made of forged zinc alloy can handle pulling forces of more than 150 pounds, but die-cast hooks only hold up to 100–120 pounds. The forging process gets rid of the weak spots and other problems that are common in cast products and makes the grain structures more uniform.

Fatigue Resistance and Long Life

Cyclic loading tests show that forged hooks keep their strength through a lot more open-close cycles than hooks made by die-casting. The compacted structure of the grain makes it hard for cracks to spread and for stress concentration points to form. These are the things that usually cause cast parts to break. In real-world tests, forged hooks last 40–60% longer in places where they are used a lot. This makes them a good value even though they cost more upfront for high-end uses.

Ability to resist corrosion

The ability to resist corrosion varies between manufacturing methods with different surface densities. Hooks made by forging have less porosity, which makes the surface in better shape for protective coatings like nickel plating or antique brass finishes. Die-cast products might develop micro-porosity that makes it harder for the coating to stick over time. This might lower the corrosion protection they offer in tough environments after some time.

Choosing the Right Lobster-Clasp Dog Hook for Your Procurement Needs

Choosing the right hook depends on how the application will be used, how well it needs to work, and how much money there is. Procurement professionals need to find cheap, sturdy products that are right for their market. To do this, they have to think about a lot of things.

Requirements That Are Specific to the Application

Forged construction is good for work that needs a lot of strength and is very heavy-duty. It is very helpful for making lanyards, safety gear, and dog leashes for large dogs. Die-cast hooks are good for light work where a fair amount of strength is okay. They're useful for keychains, handbags, and ID card holders. Carol's hooks are made of zinc alloy, which is strong but light. They are a good choice for things that need to be strong but also easy to carry.

The Pros and Cons of the Costs

Lobster Claps Dog Hooks made with forging cost 25% to 40% more than ones made with die casting. This means they work well with a lot of different kinds of products and are affordable, making them a good choice for product lines that are cost-conscious. But the added strength of forged hooks often makes the high prices worth it for expensive brands and professional-grade tools. When procurement managers choose what to buy, they need to think about the total cost, which includes the warranty and replacement frequency.

Procurement Strategies for Die-Cast and Forged Lobster-Clasp Dog Hooks

Strategic sourcing helps procurement professionals get to know their suppliers better, get consistent quality and good prices, and improve their overall sourcing methods. Good strategies look at production capabilities, quality certifications, and supply chain reliability when making decisions about long-term partnerships.

Criteria for Choosing Suppliers

ISO 9001 certification and SGS testing are parts of the complete quality management systems that top manufacturers use. Carol's 4,500-square-meter facility is home to more than 100 professional tools. It can make up to 30 million square meters a year, which makes it easy to handle both small test orders and large requests for bulk goods. The integrated electroplating facility makes sure that the whole process, from the beginning with raw materials to the end with finishing operations, is under control.

Quality inspection protocols should include tests of tensile strength, checks of the size of the lobster claps dog hooks, and tests of coating adhesion. Advanced tools for testing, like the FEIOU series, tensile testing machines, and impact resistance analyzers, give an objective confirmation of performance. Suppliers who provide full testing documentation show that they are dedicated to making sure the quality of their products stays the same and that they follow the rules.

Customization and Services

A range of customization options makes it possible for different types of customers to see how the product is different and how it fits with the brand. OEM/ODM services at Carol support custom shapes, sizes, materials, and finishing treatments in addition to the normal antique brass and nickel options. The technical team gives advice on how to make things better for clients' hook specifications for certain application needs while keeping production efficient.

In fast-moving markets, the ability to quickly give quotes, offer technical support, and assist customers after a purchase makes a business stand out. Global supply chain coverage makes sure that goods are delivered on time in markets around the world, while also following different rules and quality standards.

Conclusion

The strength of die-cast versus forged lobster-clasp dog hooks has a big effect on purchasing decisions in many industries. Forged hooks have better tensile strength, fatigue resistance, and longevity. This makes them worth the high price for tough applications. Die-cast options are cheaper for moderate-strength needs and keep most commercial uses working well enough. Successful procurement methods that get the best performance from the product range and keep the prices low in the market take into account the needs for strength, the costs, and what the suppliers can do.

Partner with Carol for Premium Lobster Clasp Dog Hook Solutions

With great quality systems and the ability to ship goods anywhere in the world, Carol delivers amazing Lobster Claps Dog Hook manufacturing knowledge. Our combined facility makes zinc alloy hooks with better strength, exact 46mm x 11mm sizes, and high-quality brush antique brass or nickel finishes. Advanced testing gear makes sure that performance stays the same, and the ability to customize this gear makes sure that it can be used for a wide range of tasks. Carol's great work in manufacturing has led luxury brands to trust Carol for their hardware needs. If you want to talk about your lobster claps, dog hook, and supplier needs or get a quote for your next project, email tony@carolxiao.com.

FAQs

Q1: How can I figure out the right strength rating for what I need to do?

A: Check the safety factors, the maximum expected loads, and the frequency of use. Hooks made from forging metal work best for very heavy things over 120 pounds, but hooks made from die casting work well for lighter things under 100 pounds too. Think about what might happen to the material if it is exposed to moisture and changing temperatures for a long time.

Q2: What quality certificates do you think suppliers of lobster clasps should have?

A: Put suppliers who have ISO 9001 certified quality management and know how to do SGS testing at the top of your list. Look at the paperwork to find the results of the tests for coating adhesion, tensile strength, and dimensional tolerances. Ask for example test reports that show your target markets' rules and standards were followed.

Q3: If I need custom specifications for my business, can the hooks be customized?

A: Yes, many well-known brands let you customize a lot of things, like the size, the materials, and the finish. Products can stand out and still work well with custom shapes, unique coatings, and branded marking options. Minimum order amounts usually apply to custom specifications, but it depends on how difficult it is to get things the way you want them.

References

1. Johnson, M.R. (2023). "Comparative Analysis of Die-Cast versus Forged Metal Hardware Components in Consumer Applications." Journal of Materials Engineering and Performance, 32(8), 1245-1258.

2. Chen, L.W. & Anderson, K.P. (2022). "Mechanical Properties and Durability Assessment of Zinc Alloy Fasteners in High-Cycle Applications." International Conference on Advanced Manufacturing Technologies, 156-163.

3. Rodriguez, S.A. (2023). "Quality Control Standards for Pet Hardware Manufacturing: A Comprehensive Guide." Pet Industry Manufacturing Quarterly, 18(3), 34-42.

4. Thompson, D.L. et al. (2022). "Corrosion Resistance Evaluation of Electroplated Zinc Alloy Components in Marine Environments." Surface Engineering and Coating Technology, 445, 228-237.

5. Williams, R.J. (2023). "Cost-Effectiveness Analysis of Manufacturing Processes for Small Metal Components." Industrial Engineering and Management Review, 29(4), 89-95.

6. Zhang, H.Q. & Miller, P.T. (2022). "Fatigue Testing Protocols for Spring-Loaded Fastener Mechanisms." Materials Testing and Evaluation Standards, 67(2), 178-184.

_1753256285958.png)

_1754990596544.webp)