Choose between cold or hot working for rectangular metal wallet frame

When it comes to manufacturing rectangular metal wallet frames, the choice between cold working and hot working is crucial, which impacts not only the production process but also the quality, durability, and overall performance of the final product. As a leading supplier of high-quality wallet frames, Carol Metal Products Co., Ltd., tells you the details.

Cold Working vs. Hot Working

Cold working and hot working are two fundamental metal forming processes used in the manufacturing industry. The rectangular metal wallet frame's attributes are directly affected by the distinctive features, benefits, and drawbacks of each method.

①Cold Working

Cold working involves shaping metal at room temperature or slightly elevated temperatures, but always below the metal's recrystallization temperature. This process is typically used for metals that are ductile enough to be formed without the need for heating.

Advantages of cold working for rectangular metal wallet frames include:

- Improved strength and hardness

- Better surface finish

- Tighter dimensional tolerances

- Reduced energy consumption

- No oxidation or scale formation

However, cold working also has some limitations:

- Higher forces required for shaping

- Limited formability for certain metals

- Potential for residual stresses

- Risk of work hardening

②Hot Working

Hot working involves shaping metal at temperatures above its recrystallization point. This process is often used for metals that are less ductile or require significant deformation.

Advantages of hot working for rectangular metal wallet frames include:

- Lower force requirements

- Increased metal ductility

- Ability to create complex shapes

- Elimination of residual stresses

- Refinement of grain structure

Limitations of hot working include:

- Potential for surface oxidation

- Less precise dimensional control

- Higher energy consumption

- Potential for grain growth

Requirements for a Rectangular Metal Wallet Frame

Before deciding between cold and hot working, it's essential to understand the specific requirements for a high-quality rectangular metal wallet frame:

① Dimensional Accuracy

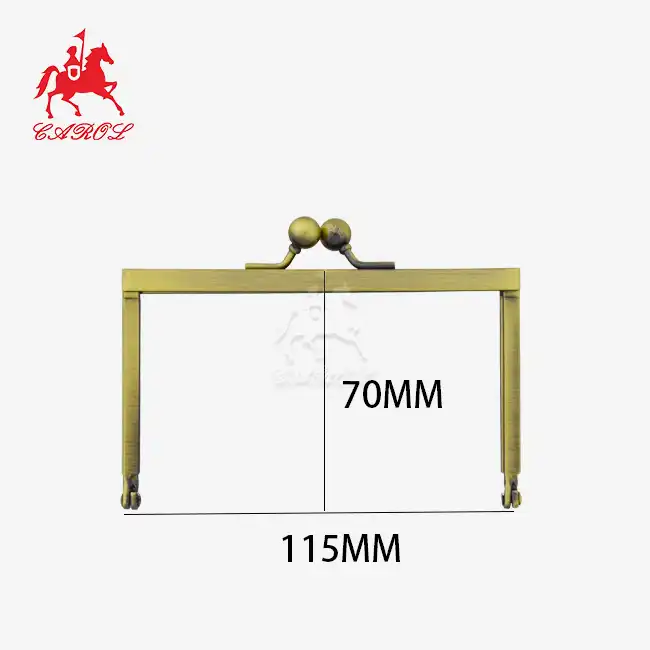

Wallet frames must maintain precise dimensions to ensure proper fit and functionality. The standard size for a rectangular metal wallet frame is typically around 11.5cm x 7cm, but custom sizes are often required to meet specific design needs.

② Surface Finish

The surface finish of a wallet frame is crucial for both aesthetic and functional reasons. Common finishes include brushed antique brass and light gold, which not only enhance the frame's appearance but also provide protection against corrosion.

③Material Properties

The material used for wallet frames must possess certain properties:

- Strength to maintain shape and support contents

- Durability to withstand daily use

- Corrosion resistance

- Ability to accept surface treatments

Iron is a common material choice due to its versatility and cost-effectiveness. However, other materials may be used based on specific requirements.

④Design Flexibility

The manufacturing process should allow for various designs and customization options to meet diverse customer needs in purse making and other applications.

Comparative Analysis: Cold Working vs. Hot Working for Wallet Frames

When choosing between cold and hot working for rectangular metal wallet frames, several factors must be considered:

①Precision and Tolerances

Cold working generally provides tighter tolerances and better dimensional accuracy, which is crucial for wallet frames that need to maintain a precise shape and size. Hot working, while offering more formability, may require additional finishing processes to achieve the same level of precision.

② Surface Finish

Cold-worked wallet frames typically have a superior surface finish straight from the forming process. This can reduce the need for extensive post-processing, making it ideal for achieving the desired brushed antique brass or light gold finish. Hot working may result in surface oxidation, requiring additional finishing steps.

③Material Strength

Cold working can increase the strength and hardness of the metal through work hardening. This can be beneficial for wallet frames that need to maintain their shape under constant use. Hot working, while not providing the same strength increase, can help refine the grain structure, potentially improving overall material properties.

④ Design Complexity

For simple rectangular shapes, cold working is often sufficient and cost-effective. However, if more complex designs or significant deformation is required, hot working may be necessary due to its ability to create intricate shapes with less force.

⑤ Production Volume and Cost

Cold working typically requires higher initial forces but can be more cost-effective for large production volumes due to lower energy consumption and faster processing times. Hot working may be more suitable for smaller batches or when working with less ductile materials.

⑥ Material Considerations

The choice between cold and hot working also depends on the specific material being used. Iron, the primary material for many wallet frames, can be processed using either method. However, the final decision should be based on the desired properties of the end product.

In conclusion, the choice between cold and hot working for rectangular metal wallet frames depends on a balance of factors including precision requirements, surface finish needs, material properties, design complexity, and production volume. At Carol Metal Products Co., Ltd., we understand these nuances and offer expertise in both cold and hot working processes to ensure the highest quality wallet frames for our customers.

As a trusted leading global supplier of rectangular metal wallet frames, Carol Metal Products Co., Ltd. specializes in delivering tailored, fully customizable solutions, designed to align with your unique functional requirements, brand aesthetics, and production scales. Whether you're developing a niche luxury line, scaling up for mass-market distribution, or needing specialized specs for unique wallet designs, our team works closely with you to turn concepts into tangible, high-quality hardware.

Our rectangular metal wallet frames stand out for their versatility and craftsmanship: we offer an extensive selection of sizes (from compact cardholder frames to full-sized billfold dimensions), colors (including on-trend metallic finishes like rose gold, gunmetal, and matte black, plus custom color-matching for brand-specific palettes), and premium materials (such as corrosion-resistant stainless steel, lightweight aluminum alloy, and durable brass—all sourced for strength and long-term performance). These frames are the ideal choice for diverse applications:

- Purse & wallet crafting (supporting styles from sleek leather clutches to rugged everyday crossbody wallets);

- Bulk frame supply for accessory manufacturers, ensuring consistent specs for large production runs;

- High-performance closure hardware, engineered to deliver smooth, secure functionality that enhances the end-user experience.

To explore our range of rectangular metal wallet frames or discuss your custom requirements, please contact us at tony@carolxiao.com.

References

- ASM International. (2015). ASM Handbook, Volume 14A: Metalworking: Bulk Forming.

- Kalpakjian, S., & Schmid, S. R. (2014). Manufacturing Engineering and Technology. Pearson.

- Groover, M. P. (2010). Fundamentals of Modern Manufacturing: Materials, Processes, and Systems. John Wiley & Sons.

- DeGarmo, E. P., Black, J. T., & Kohser, R. A. (2011). Materials and Processes in Manufacturing. John Wiley & Sons.

- Dieter, G. E., & Bacon, D. (1988). Mechanical Metallurgy. McGraw-Hill.

_1753256285958.png)

_1754990596544.webp)