Which zinc alloy grades are best for die casting doghooks?

Doghooks' performance directly depends on the material chosen for manufacturing, and zinc alloy die casting has emerged as the preferred process for mass-producing doghooks due to its ability to create complex shapes with high precision, cost-effectiveness, and balanced mechanical properties. However, not all zinc alloys are equally suited for this purpose. The ideal zinc alloy for die casting dog hooks must align with core requirements such as good fluidity (for intricate designs), sufficient strength (to withstand daily pulling or loading), corrosion resistance (to prevent rust in diverse environments), and compatibility with surface finishes (e.g., E-coating, plating). Among the various zinc alloy grades available, three stand out for their ability to meet these needs: Zamak 3, Zamak 5, and Zamak 7.

Recommended Grade: Zamak 3 (ASTM B86, UNS Z33520)

Zamak 3, defined by ASTM B86 and designated as UNS Z33520, is the most widely used zinc alloy for die casting dog hooks globally, and for good reason. Its balanced combination of performance, castability, and cost-effectiveness makes it the ideal choice for the majority of standard doghook applications.

Composed primarily of 96.5% zinc, 3.5% aluminum, and trace amounts of magnesium (approximately 0.05%), Zamak 3 exhibits a set of properties that directly address the key needs of doghook manufacturing. One of its most notable strengths is its excellent fluidity during the die casting process. This characteristic allows the molten alloy to fill even the most complex mold cavities with ease, ensuring that doghooks with intricate structures, such as detailed hooks, integrated rings, or small locking mechanisms, are produced with consistent shape and minimal defects like porosity or incomplete filling.

For example, a standard 68mm×40mm doghook with a thin-walled ring and a tapered hook tip requires alloy fluidity to capture these fine details, and Zamak 3 delivers this reliably, reducing scrap rates and ensuring batch consistency.

Zamak 3 provides good natural corrosion resistance, thanks to the thin oxide layer that forms on its surface when exposed to air. This layer acts as a barrier against mild moisture, and when combined with common surface treatments like E-coating or nickel plating, it becomes even more resistant to rust, making it suitable for indoor and outdoor use in non-harsh environments.

While Zamak 3 excels in standard scenarios, some doghook use cases demand higher structural performance, such as heavy-duty pet leashes for large dogs or industrial bag straps that bear significant, prolonged loads. In these situations, an alloy with enhanced strength and hardness is necessary to prevent deformation or failure. This is where Zamak 5, a high-strength variant of Zamak, becomes the optimal solution.

High-Strength Option: Zamak 5 (ASTM B86, UNS Z33520)

Zamak 5, also specified by ASTM B86 and classified as UNS Z35530, is an upgraded zinc alloy designed to deliver superior strength and hardness compared to Zamak 3, making it the go-to choice for dog hooks that require enhanced durability under heavy loads.

Its composition differs slightly from Zamak 3, with 95.5% zinc, 4.0% aluminum, 0.5% copper, and 0.05% magnesium. The addition of copper is the key modification here: it increases the alloy's tensile strength to approximately 320 MPa (a 15–20% improvement over Zamak 3) and raises its Brinell hardness to 80–90 HB (compared to 65–75 HB for Zamak 3). This boost in mechanical properties enables Zamak 5 to withstand the higher stresses associated with heavy-duty applications, such as the pulling force of large dogs (which can exceed 150N) or the weight of industrial equipment carried in heavy-duty backpacks or tool belts.

Another critical advantage of Zamak 5 is its excellent dimensional stability. During die casting, the alloy exhibits a lower shrinkage rate than Zamak 3, ensuring that doghooks maintain precise dimensions even after cooling.

Additionally, the alloy's increased hardness enhances its wear resistance, which is beneficial for zinc alloy die casting doghooks that are frequently opened and closed or rubbed against other materials (e.g., metal D-rings on bags or leash hardware). This wear resistance reduces the risk of premature failure due to abrasion, extending the product's service life in high-use environments.

While Zamak 3 and Zamak 5 address most strength and castability needs, there is a third category of doghook applications where corrosion resistance takes precedence over minor trade-offs in strength: these include outdoor pet leashes exposed to rain, marine-themed bag accessories, or products used in coastal regions with high salt humidity. For these scenarios, Zamak 7 offers the specialized corrosion resistance required to prevent rust and maintain performance.

Corrosion-Resistant Option: Zamak 7 (ASTM B86, UNS Z33521)

Zamak 7, specified by ASTM B86 and designated as UNS Z33521, is a corrosion-resistant zinc alloy tailored for doghooks used in humid, wet, or harsh environments.

Its composition is optimized for rust prevention: it contains 96.0% zinc, 3.5% aluminum, 0.05% magnesium, and significantly lower lead content than Zamak 3 or Zamak 5. This reduction in lead, combined with a refined alloy structure, minimizes the risk of galvanic corrosion and oxidation, two common causes of rust in zinc alloys exposed to moisture.

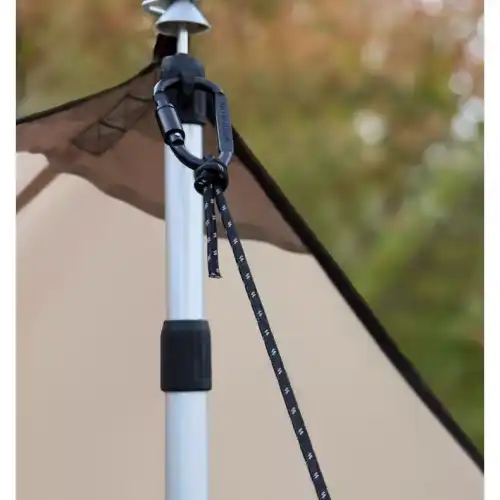

In practical terms, this means Zamak 7 can withstand exposure to rain, pet saliva, salt spray (in coastal areas), or humid conditions (e.g., bathroom accessories) without developing red rust or significant degradation. For example, a dog hook used on an outdoor camping leash that is frequently exposed to rain will maintain its structural integrity and appearance for longer when made from Zamak 7 compared to Zamak 3 or 5.

To quantify its corrosion resistance, Zamak 7 typically undergoes neutral salt spray testing per ASTM B117, a standard method for evaluating how materials withstand corrosive environments. In these tests, samples are exposed to a 5% sodium chloride solution (simulating saltwater) at 35°C for 48 hours. Zamak 7 consistently shows minimal corrosion: at most, a slight white oxide film forms on its surface, which can be easily wiped away without damaging the alloy or any applied coatings.

In contrast, Zamak 3 and 5 may develop small patches of red rust under the same conditions, especially if their surface finish is compromised. This level of corrosion resistance makes Zamak 7 ideal for doghooks that are used outdoors or in damp environments, where rust not only affects appearance but also weakens the alloy over time.

Selecting the right zinc alloy grade for die casting doghooks is crucial for ensuring product quality, durability, and performance. Whether you require the balanced properties of Zamak 3, the increased strength of Zamak 5, or the enhanced corrosion resistance of Zamak 7, Shenzhen Carol Metal Products Co., Ltd. has the expertise and capabilities to meet your needs.

We invite you to experience the Carol difference in zinc alloy die casting doghooks. Our factory-customized 40MM zinc alloy die casting doghook rectangle ring is just one example of our commitment to quality and customization. With options for E-Coating Gunmetal or E-Coating Coffee finishes, and the ability to customize sizes, colors, and materials, we ensure that your specific requirements are met with precision and care.

Ready to elevate your product line with high-quality zinc alloy die casting doghooks? Contact us today at tony@carolxiao.com to discuss your project needs or request a quote. Let Carol be your trusted partner in creating durable, stylish, and functional doghooks that exceed your expectations.

References

- ASTM International. (2024). ASTM B86 - Standard Specification for Zinc-Alloy Die Castings. West Conshohocken, PA: ASTM International.

- Davis, J. R. (Ed.). (2021). ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials. Materials Park, OH: ASM International.

- Campbell, J. (2019). Castings (5th ed.). Oxford, UK: Butterworth-Heinemann.

- Smith, A. K., & Jones, L. M. (2022). Corrosion Behavior of Zinc Alloys for Consumer Hardware Applications. Journal of Materials Engineering and Performance, 31(4), 2105-2118.

- Zinc Die Casting Association. (2023). Zinc Alloy Selection Guide for Consumer and Industrial Hardware. Chicago, IL: Zinc Die Casting Association.

- Brunton, J. H., & Rawlings, R. D. (2020). Die Casting of Zinc Alloys: Process-Material-Property Relationships. Materials Science and Engineering: R: Reports, 141, 100586.

_1753256285958.png)

_1754990596544.webp)