How to choose high-quality metal frame for bag making?

Although steel frames are very long-lasting, they can oxidize in damp settings unless coated with a protective material. Metal frames serve as the architectural backbone of purses, clutches, and evening bags, providing both structural integrity and aesthetic appeal. Professional bag makers understand that inferior hardware can compromise months of careful craftsmanship, while premium metal frames elevate even modest designs into coveted accessories.

Material Quality: The Foundation of Durability

Material composition directly impacts frame performance across multiple stress factors including corrosion resistance, mechanical strength, and dimensional stability. Premium metal frames typically utilize steel alloys or brass compositions that provide superior tensile strength while maintaining workable properties for manufacturing processes. The base metal selection influences both the frame's ability to maintain shape under load and its compatibility with various finishing treatments.

Although steel frames are very long-lasting, they can oxidize in damp settings unless coated with a protective material. High-carbon steel variants provide increased strength but may present challenges during installation due to their hardness. Conversely, brass frames naturally resist corrosion while offering easier manipulation during assembly, though they command higher material costs. Iron-based frames, while economical, necessitate robust plating systems to achieve acceptable longevity.

Because protective coatings dictate both the material's aesthetic appeal and its practical longevity, surface finishing is another important factor to consider when selecting a material. Electroplating processes, particularly nickel-free light gold applications, provide elegant appearance while meeting contemporary safety standards. Metal finishes coated with PVD provide superior protection against rust and corrosion, greatly outlasting plating approaches in terms of service life.

Inspect Craftsmanship Details: Markers of Fine Quality

Manufacturing precision manifests in numerous observable characteristics that distinguish exceptional frames from mediocre alternatives. Edge finishing quality immediately reveals attention to detail, as premium frames exhibit smooth, consistent surfaces without burrs or sharp transitions. Dimensional accuracy becomes apparent through consistent spacing, parallel surfaces, and uniform thickness measurements across the frame's geometry.

Joint construction represents another critical evaluation point, particularly where hinges or articulating components connect. Professional-grade frames demonstrate precise fit between moving parts, with minimal backlash and smooth operation throughout their range of motion. Welding or brazing joints should appear clean and fully penetrated, without visible voids or excessive material buildup that could compromise strength or appearance.

Mechanical operation provides immediate feedback regarding manufacturing quality, as poorly crafted frames exhibit binding, excessive play, or irregular motion patterns. High-quality hardware operates smoothly and feels substantial during use, with consistent resistance throughout opening and closing cycles. Spring mechanisms, where present, should provide predictable force curves without sudden releases or binding conditions.

Surface preparation quality becomes evident through coating adhesion and uniform appearance across complex geometries and Metal frame. Professional finishing processes eliminate contamination and surface irregularities that could compromise coating integrity. Color consistency across multiple frame components indicates controlled processing conditions and quality manufacturing practices.

Tolerance maintenance demonstrates manufacturing capability through consistent reproduction of critical dimensions. Frames requiring assembly into leather goods must maintain precise spacing and alignment to ensure proper fit and function. Measuring key dimensions with appropriate instruments reveals manufacturing consistency and identifies frames suitable for professional applications.

Packaging and documentation accompanying quality frames often reflects overall manufacturing standards. Professional suppliers provide clear installation instructions, dimensional drawings, and compatibility information that facilitates successful integration into finished products. Protective packaging prevents damage during shipping and storage while demonstrating concern for product integrity.

Match Frame Structure to Bag Type & Function

Structural requirements vary dramatically across different bag categories, necessitating careful frame selection based on intended use patterns and design aesthetics. Evening bags typically require delicate frames that complement formal styling while providing adequate closure security. Conversely, everyday handbags demand robust construction capable of withstanding frequent use and varying load conditions.

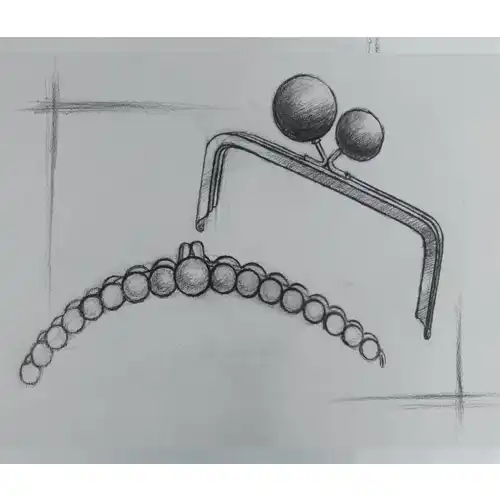

Frame geometry must accommodate the intended bag volume and shape while providing appropriate opening dimensions for user access. Curved frames suit rounded bag profiles but may complicate pattern development and assembly processes. Rectangular configurations offer manufacturing simplicity but may not complement flowing design lines. Custom frame dimensions become necessary for unique designs but often require minimum order quantities that challenge smaller operations.

Closure mechanisms require matching to user expectations and bag functionality requirements. Kiss-lock closures provide secure retention but may prove challenging for users with limited dexterity. Twist-lock mechanisms offer elegant operation but require precise manufacturing tolerances for proper function. Magnetic closures deliver convenience but may not provide adequate security for valuable contents.

Load distribution characteristics become critical for larger bags or those intended to carry substantial weight. Frame mounting points and Metal frames must align with bag construction to prevent stress concentrations that could lead to premature failure. Handle attachment considerations influence frame design, particularly when integrated handle systems are specified.

Metal Frame for Bag Making Supplier: Carol

Carol is unparalleled in the global market for premium hardware attachments for handbags. Given her wealth of experience in product development, manufacturing, and design innovation, Carol is a priceless asset to professional manufacturers and crafters. In order to fulfill the varied and regular needs of its customers, the company offers a wide variety of items, including frames, clasps, handles, buckles, locks, and custom hardware components.

Because they use combined manufacturing, the company can handle all stages of production, from planning to packing. This gives them a big advantage. Carol can do electroplating that is very advanced and can be used on any surface and Metal frames while still keeping high quality standards. One-line service, which includes designing, taking orders, producing, plating, and packing, makes things easier for customers and cuts down on wait times.

The characteristics of a first-rate product include a nice look, consideration for the environment, adherence to safety regulations, and a lengthy lifespan. Even after a consumer has paid for Carol's goods or services, she still goes out of her way to ensure their satisfaction. In the event that any problems arise with the product's functionality, she is there to provide technical support. When it comes to brand needs and design criteria, OEM/ODM capabilities allow for personalized solutions.

Carol is the only person professional bag makers go to when they need solid hardware solutions. This is because she knows so much about production, quality control, and customer service. They stay on top of the latest handbag trends by using safe, eco-friendly materials and making patterns that are one of a kind. This meets the needs of current customers.

Contact Carol today at tony@carolxiao.com to discuss your specific requirements and discover how their expertise can elevate your next creation.

References

1. Intertek. (2024). "Luggage and Bags Testing: Strength and Durability Assessment."

2. Gunas New York. (2023). "How to Determine Handbag Quality: Hardware and Construction Standards."

3. LESONDI. (2025). "The Ultimate Guide to Bag Hardware Types: Durability and Design Integration."

4. NBNQC. (2024). "Essential Tests for Handbags Pre-Shipment Inspection: Quality Assurance Procedures."

5. Supply4Bag. (2024). "Premium Quality Metal Purse Frame Manufacturing and Customization."

_1753256285958.png)

_1754990596544.webp)