Material Properties

The fundamental differences between metal and plastic heavy-duty buckles stem from their distinct material properties. Metal buckles, typically made from zinc alloy, stainless steel, or other sturdy metal alloys, offer superior strength, rigidity, and resistance to environmental factors. For applications that require a high degree of durability and a posh feel, metal buckles are an excellent choice.

For example, zinc alloy is the perfect material for hook buckles on heavy-duty accessories because it combines the strength of metal with relatively low weight. Metal buckles' resilience to corrosion and wear and tear guarantees that they will continue to operate and look good even after prolonged usage.

On the other hand, plastic buckles are generally made from materials such as nylon, acetal, or polypropylene. Despite having benefits like lightweight construction and lower manufacturing costs, these materials usually lack overall durability and strength when compared to their metal counterparts. Heavy-duty accessories hook buckle made of plastic may be more susceptible to cracking, warping, or breaking under extreme conditions or prolonged stress.

But because of advancements in polymer science, high-performance polymers that can offer greater strength and endurance have been created. These enhanced plastic materials may be suitable for certain applications where weight is a critical factor, but they still generally cannot match the overall robustness of metal buckles.

Fatigue Resistance

The durability and dependability of heavy-duty accessory hook buckles are greatly influenced by fatigue resistance. The capacity of a material to endure multiple stress cycles without failing is referred to as this attribute. In the context of bag hardware, fatigue resistance directly impacts how well a buckle can maintain its structural integrity over countless uses.

Metal buckles, particularly those made from high-quality alloys, exhibit superior fatigue resistance compared to plastic alternatives. Metals may better distribute stress thanks to their crystalline structure, which lowers the possibility of abrupt failure from repeated cycles of loading and unloading. For buckles used in applications that need frequent opening and shutting, as those on backpacks, messenger bags, or luggage, this feature is particularly crucial.

Zinc alloy buckles, for example, can withstand thousands of stress cycles without significant degradation in performance. Because of their tenacity, heavy-duty accessories hook buckle will continue to be strong and useful and preserve their shape even after years of frequent usage. Metal buckles' better fatigue resistance results in longer product lifespans and happier customers.

Plastic buckles, while capable of handling moderate stress cycles, generally have lower fatigue resistance compared to their metal counterparts. Microcracks or structural weakening may occur in plastic materials over time, which might result in an abrupt breakdown under strain. This lower fatigue resistance can be particularly problematic for heavy-duty applications or in environments where the buckle is subjected to frequent stress.

It's important to note that the fatigue resistance of plastic buckles can vary significantly depending on the specific polymer used and its quality. High-performance engineering plastics may offer improved fatigue resistance, but they often come at a higher cost and still may not match the long-term durability of metal options.

Load Limit

A heavy-duty accessory hook buckle's load limit is an important factor to take into account, particularly in applications where there is a lot of weight or strain. This factor determines the maximum amount of force or weight a buckle can safely bear without failing or experiencing permanent deformation. To guarantee product safety and dependability, it is crucial to comprehend the load limitations of metal and plastic buckles.

Metal buckles, due to their inherent material properties, generally offer substantially higher load limits compared to plastic alternatives. For instance, a zinc alloy heavy-duty accessories hook buckle can typically support loads many times greater than its own weight without compromising its structural integrity. Because of their great load-bearing capability, metal buckles are perfect for uses like heavy-duty backpacks, big travel bags, and industrial equipment where a lot of stress is anticipated.

Metal buckles' greater load limit also acts as a safety buffer, enabling them to endure sudden increases in tension without breaking. When overloading may occur, such as with full suitcases or unanticipated bumps during travel, this function is quite useful.

Plastic buckles, while capable of handling moderate loads, generally have lower load limits compared to metal options. The load-bearing capacity of plastic buckles can vary widely depending on the specific polymer used, its thickness, and design. While some high-performance plastics can offer improved load limits, they typically fall short of the capabilities offered by metal buckles.

It's worth noting that the load limit of a buckle is not solely determined by its material. A buckle's overall strength and load-bearing capacity are mostly dictated by its design, which includes components like shape, thickness, and reinforcing elements. However, even with optimal design, plastic buckles generally cannot match the load limits of their metal counterparts in heavy-duty applications.

It's important to take your application's particular load requirements into account when choosing between metal and plastic heavy-duty accessory hook buckles. For products that will often be subjected to large loads or stress, metal buckles offer a clear benefit in terms of safety, dependability, and durability.

Heavy - Duty Accessories Hook Buckle Supplier: Carol

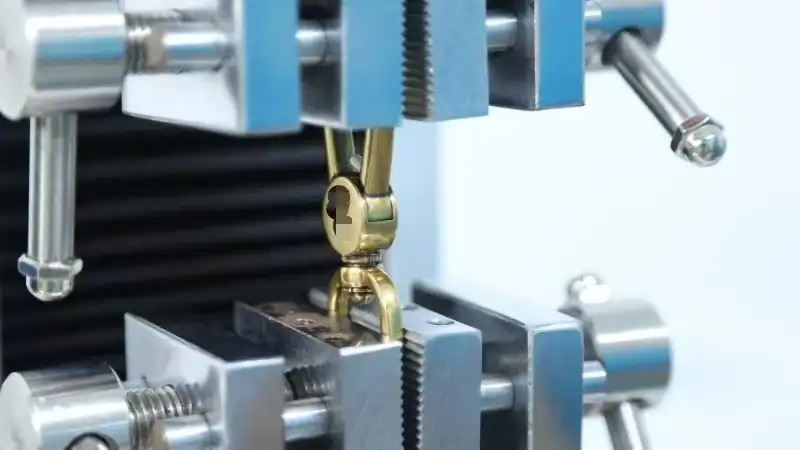

For manufacturers seeking high-quality, durable, heavy-duty accessory hook buckles, Carol Metal Products Co., Ltd. provides outstanding solutions suited to your particular requirements. Our Customizable Heavy-Duty Accessories Hook Buckle, made from premium zinc alloy, exemplifies the superior properties of metal buckles discussed in this article.

With dimensions of 83mm x 15mm and a weight of 36.3 grams, our hook buckle combines strength with practicality. Belting, handbags, straps, leathercraft, and even pet accessories may all benefit from its many uses, which include finishes like Antique Silver and Matt Gunmetal. As a professional factory with years of experience in hardware accessories and metal frames for handbags, leather goods, and luggage, we pride ourselves on our ability to customize sizes, colors, and materials to meet your exact requirements.

Our in-house electroplating facility guarantees superior beauty, eco-friendly materials, and unparalleled durability through a smooth production process from design to packing. For top-quality heavy-duty accessories hook buckle that will enhance the value and longevity of your products, contact us at tony@carolxiao.com. Let Carol be your trusted partner in creating exceptional, durable bag hardware.

_1753256285958.png)

_1754990596544.webp)