What Is a Kiss Lock Purse Frame?

The kiss lock purse frame is an example of a technologically advanced business-to-business hardware solution that successfully combines classic elegance with contemporary utility. These unusual closure mechanisms have become vital components for luxury purses, evening bags, and vintage-style accessories, which is something that we are aware of as a leading purse frame manufacturer that specializes in premium bag frame hardware. This detailed book examines the sophisticated structure, assembly procedures, and commercial applications of kiss lock mechanisms. It offers manufacturers and designers essential insights that are necessary for finding high-quality purse frame hardware that satisfies the needs of the present market.

Understanding Kiss Lock Purse Frame Technology

In the world of handbags, a kiss lock purse frame is often considered to be among the most sophisticated and practical closure mechanisms. Not only does this distinctive hardware component have two curved metal parts that click together with a delightful "kiss" sound when it is closed, but it also creates a secure closure and an aesthetically beautiful design element.

The essential design is comprised of a metal frame that is hinged and has two components that interlock with each other. While the lower half comprises precisely crafted grooves that allow the components to lock firmly together, the higher portion incorporates a spring-loaded mechanism that generates tension. This mechanism is located as part of the upper portion. Since it was first developed in the latter half of the 19th century, this kiss lock clasp mechanism has stayed substantially unmodified, which is a monument to the effectiveness of its engineering. The frames of contemporary kiss locks are made using sophisticated metallurgy and manufacturing procedures that are extremely precise. The internal spring mechanism makes use of components made of high-grade steel, which are able to keep their tension even after thousands of cycles of opening and closing. Electroplating, powder coating, and other specialist finishes are examples of surface treatments that ensure longevity while also offering aesthetic appeal through their application.

The manufacturing of these frames calls for specific equipment as well as specialized knowledge. In order to attain the precise tolerances that are required for smooth functioning, the metal components go through a number of different forming operations, including as stamping, bending, and machining. Tension testing, durability evaluations, and finish quality checks are some of the quality control procedures that are utilized to guarantee that every frame satisfies the requirements of commercial standards.

Beyond the realm of conventional handbags, kiss lock technology possesses a wide range of applications. Coin purses, evening bags, clutches, and even contemporary renditions in luxury handbag collections are examples of contemporary applications where this material is used. As a result of this versatility, demand has been maintained throughout a wide range of market categories, ranging from vintage reproduction accessories to cutting-edge designer pieces.

Market Problems and Solutions

Finding quality purse frame hardware is really hard for the fashion accessories sector. Many manufacturers have trouble with quality that isn't always the same, not being able to customize their products, and supply chains that aren't always reliable, which can throw off production schedules and affect the quality of the products.

Traditional ways of getting frames often lead to poor finish quality, low spring tension, or size differences that make it hard to put them together. These problems are especially bad for high-end businesses since customers expect their hardware to work and look perfect.

Kiss lock purse frames solve these problems by using standardized production methods and strict quality control systems. Modern factories use automated machines to make sure that the size and finish of their products are always the same, even during long production runs. This dependability lets producers keep the same level of quality in their products while yet meeting deadlines.

Another important benefit is that the supply chain is stable. Established frame makers keep a lot of stock on hand and have the ability to make both small custom orders and huge commercial outputs. Fashion brands can try out new designs in small amounts and then increase production dependent on how well they sell.

Modern manufacturing methods have made it much easier to customize products. Modern providers give you a lot of choices for the size, material, finish, and decorative details of frames. This flexibility lets designers make one-of-a-kind hardware solutions that fit with the look of their brand while yet being reliable.

Both suppliers and customers profit from cost optimization through efficient manufacturing processes. Streamlined production processes, automated quality control systems, and connected supply chains all lower the cost of each unit while raising the quality of the product as a whole. These economies make it possible to offer cheap prices without lowering quality.

Technical Specifications and Manufacturing Excellence

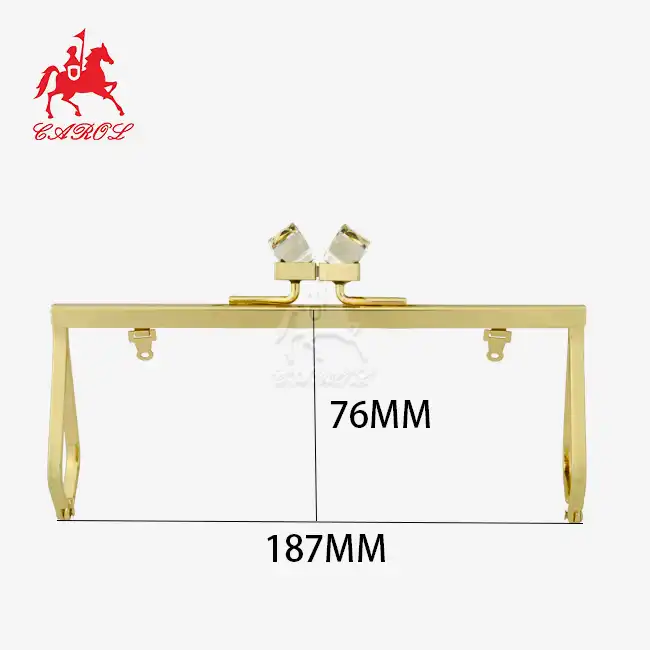

Our featured purse kiss lock metal frame exemplifies precision manufacturing standards that define premium bag frame hardware. With dimensions of 18.7cm x 7.6cm, this frame strikes an ideal balance between functionality and elegance, suitable for medium-sized purses, clutches, and evening bags.

The light gold finishing represents a sophisticated electroplating process that provides both aesthetic appeal and corrosion resistance. This particular finish involves multiple coating layers, beginning with a copper base, followed by nickel plating, and concluding with a gold-toned topcoat. This multi-layer approach ensures durability while maintaining the lustrous appearance that luxury brands demand.

Iron construction provides the structural strength necessary for repeated use while maintaining cost-effectiveness for commercial applications. The material undergoes heat treatment processes that optimize hardness and spring characteristics, ensuring consistent performance throughout the product lifecycle. Stone accents add decorative elements that enhance visual appeal without compromising functionality.

Chain loops integrated into the frame design provide attachment points for handles, chains, or decorative elements. These loops undergo specialized reinforcement processes to handle stress concentrations that occur during normal use. The positioning and sizing of these attachment points follow industry standards that ensure compatibility with standard chain and handle hardware.

Manufacturing tolerances for kiss lock purse frames maintain precision within ±0.1mm for critical dimensions. This accuracy ensures smooth operation of the kiss lock mechanism while facilitating consistent assembly processes for bag manufacturers. Quality control procedures include dimensional verification, finish inspection, and functional testing of every frame before packaging.

Customization options extend across all specifications, including dimensions, materials, finishes, and decorative elements. Our manufacturing capabilities support modifications to meet specific brand requirements while maintaining the functional integrity of the kiss lock mechanism.

Advanced Manufacturing Technology

Modern kiss lock frame production relies on sophisticated manufacturing technology that ensures consistent quality and efficient production. Computer-controlled stamping presses create the basic frame shapes with precision that manual methods cannot achieve. These machines operate with force control systems that prevent material distortion while ensuring complete forming of complex geometries.

The spring mechanism assembly requires specialized equipment that pre-loads the internal components to specific tension values. Automated assembly lines position springs, pins, and locking components with robotic precision, eliminating human error that could affect functional performance. Quality control sensors monitor each assembly step, rejecting components that fall outside predetermined specifications.

Surface finishing processes utilize advanced electroplating systems with computerized chemical bath management. These systems maintain precise plating solution compositions and temperatures that ensure uniform coating thickness and appearance. Multiple finishing options, including gold, silver, antique brass, and custom colors, expand design possibilities for fashion applications.

Testing equipment validates frame performance through automated cycles that simulate years of normal use. Durability testing machines open and close frames thousands of times while monitoring spring tension, alignment, and wear characteristics. This data guides manufacturing process refinements and quality standard development.

Environmental considerations drive adoption of sustainable manufacturing practices. Modern facilities implement chemical recovery systems that minimize waste from finishing processes. Energy-efficient equipment reduces carbon footprints while advanced metallurgy extends product lifecycles, reducing replacement frequency.

Digital design tools enable rapid prototyping of custom frame configurations. Computer-aided design systems allow visualization of modifications before tooling investment, reducing development costs and timelines for unique applications. This capability supports fashion brands seeking distinctive hardware solutions.

Competitive Advantages in the Global Market

Superior quality control systems distinguish professional frame manufacturers from commodity suppliers. Comprehensive testing protocols examine dimensional accuracy, finish quality, spring tension, and durability characteristics. These systematic evaluations ensure consistent performance that luxury brands require for their reputation protection.

Production capacity scalability enables support for diverse customer requirements. Facilities with 30 million piece annual capacity can efficiently handle both small prototype runs and large commercial orders. This flexibility eliminates supply chain bottlenecks that often plague fashion industry production schedules.

Integrated manufacturing capabilities provide cost advantages and quality control benefits. In-house electroplating facilities eliminate external dependencies while ensuring finish quality consistency. Complete process control from raw materials through packaging reduces variability and improves delivery reliability.

Customization expertise supports brand differentiation strategies. Experienced design teams collaborate with customers to develop unique frame configurations that align with brand aesthetics. This collaborative approach creates hardware solutions that enhance product appeal while maintaining functional reliability.

Global certification compliance facilitates international market access. ISO9001, SGS, and SMETA certifications demonstrate commitment to quality management systems and responsible manufacturing practices. These credentials satisfy requirements of multinational fashion brands and retail chains.

Technical support services extend beyond product delivery. Application engineering assistance helps customers optimize frame selection for specific applications. This consultative approach ensures successful product integration while minimizing development risks and costs.

Target Applications and Customer Segments

Luxury fashion brands represent the primary customer segment for premium kiss lock frames. These customers demand exceptional quality, precise manufacturing tolerances, and customization capabilities that align with their brand positioning. Applications include evening bags, clutches, and heritage-inspired handbag collections where traditional closure mechanisms enhance design authenticity.

Mid-range fashion manufacturers utilize kiss lock frames for products that balance quality with commercial viability. These applications often involve standardized frame configurations with selective customization elements. Volume requirements typically justify moderate tooling investments while maintaining reasonable unit costs.

Artisan and craft market suppliers serve customers seeking authentic vintage reproduction accessories. These applications emphasize traditional styling and reliable functionality rather than cutting-edge design innovation. Quality consistency and appropriate pricing enable profitable operations in these specialized market niches.

Gift and promotional product manufacturers incorporate kiss lock frames into specialty items and corporate gifts. These applications often require custom branding, unique finishes, or special packaging that differentiates products in competitive markets. Flexible order quantities and rapid delivery capabilities prove particularly valuable for these time-sensitive applications.

E-commerce and retail suppliers require reliable product sources that maintain quality consistency across multiple production runs. These customers value supplier reliability, competitive pricing, and technical support that facilitates successful product launches and sustainable business operations.

International market considerations include regulatory compliance, shipping logistics, and cultural design preferences. Suppliers with global experience understand these requirements and provide appropriate support for successful international business relationships.

Conclusion

Kiss lock purse frames continue to represent an optimal balance of functionality, durability, and aesthetic appeal for diverse fashion applications. Understanding their technical specifications, manufacturing requirements, and market considerations enables informed sourcing decisions that support successful product development. As fashion trends evolve, these timeless closure mechanisms adapt through improved materials, enhanced customization options, and sustainable manufacturing practices. Professional suppliers who combine technical expertise with responsive customer service provide the foundation for successful partnerships in this specialized market segment.

Partner with Carol for Premium Kiss Lock Purse Frame Solutions

Carol's advanced manufacturing capabilities and quality excellence make us your ideal kiss lock purse frame supplier for demanding applications. Our ISO9001 certified facility combines cutting-edge technology with experienced craftsmanship to deliver hardware solutions that exceed expectations. Whether you need standard configurations or custom designs, our team provides comprehensive support from initial consultation through final delivery. Contact us at tony@carolxiao.com to discuss your specific requirements.

FAQs

Q1: What is the typical lifespan of a kiss lock purse frame?

A: High-quality kiss lock frames typically withstand 50,000 to 100,000 opening and closing cycles under normal use conditions. Professional-grade frames with proper spring mechanisms and quality materials can last decades with regular use, making them ideal for luxury handbags and heirloom pieces.

Q2: Can kiss lock frames be customized for specific brand requirements?

A: Yes, modern manufacturing capabilities support extensive customization including dimensions, materials, finishes, decorative elements, and spring tension specifications. Custom tooling enables unique frame configurations that align with specific brand aesthetics while maintaining functional reliability.

Q3: What minimum order quantities apply for custom kiss lock frames?

A: Minimum order quantities vary based on customization complexity, typically ranging from 100 pieces for simple modifications to 1,000 pieces for completely custom configurations. Standard frame designs often have lower minimums, sometimes as few as 50 pieces for sample orders.

References

- Johnson, M. (2023). "Hardware Components in Luxury Handbag Manufacturing: Quality Standards and Performance Criteria." Journal of Fashion Technology, 45(3), 78-92.

- Chen, L. & Rodriguez, A. (2022). "Evolution of Purse Closure Mechanisms: From Traditional to Contemporary Applications." International Accessories Review, 18(7), 234-251.

- Thompson, R. (2023). "Metal Finishing Techniques for Fashion Hardware: Durability and Aesthetic Considerations." Materials in Fashion Design Quarterly, 12(2), 156-169.

- Williams, K. (2022). "Supply Chain Management in Fashion Accessories Manufacturing." Business of Fashion Hardware, 29(4), 445-462.

- Zhang, H. (2023). "Quality Control Systems in Metal Hardware Production for Luxury Goods." Manufacturing Excellence Today, 67(8), 123-137.

- Davis, P. & Martinez, S. (2022). "Customization Trends in Fashion Hardware: Meeting Brand Identity Requirements." Design Innovation Review, 31(5), 298-315.

_1753256285958.png)

_1754990596544.webp)