As we move into 2025, manufacturers and designers are reinventing how these little yet critical components might enhance user experience while expressing contemporary ideals. The modern buyer requests items that adjust with natural values, offer consistent execution, and guarantee solidness whereas keeping up stylish offer. Professional factories specializing in hardware accessories have reacted by creating unique solutions that fulfill these altering specifications.

Sustainability-Driven Materials

Environmental responsibility has become the cornerstone of modern wallet hardware hinge development. Manufacturers are ditching traditional production methods in favor of eco-friendly choices that minimize carbon footprints without compromising structural integrity. Recycled metals now dominate the material selection process, with brass and iron components sourced from post-consumer waste streams.

Coats made from bio-based materials speak to another critical headway in the feasible generation of pivots. The progressed coatings give remarkable erosion resistance and kill the require for hurtful substances utilized in electroplating strategies. With the industry moving toward water-based surface medications, producers must reassess the strength of their items. This has driven to the advancement of pivots that stand up to dampness and hold their visual charm for expanded periods.

Supply chain transparency has become equally important in material selection. Responsible manufacturers now trace raw materials from extraction to final assembly, ensuring ethical sourcing practices throughout the production cycle .Women consumers are increasingly investigating brand values before making buying choices, resulting in a demand for hardware components made under fair labor practices.

Minimalist, Embedded Hinge Designs

Contemporary wallet design philosophy embraces clean lines and uncluttered surfaces, pushing hinge mechanisms toward seamless integration rather than prominent display. Embedded hinge systems virtually disappear within wallet construction, creating smooth profiles that enhance both tactile experience and visual appeal. Engineering teams have developed ultra-thin hinge components that maintain full functionality while occupying minimal space.

The highest achievement of minimalist design is represented by hidden pivot mechanisms. Installed beneath leather or fabric surfaces, these systems enable smooth openings and closings without visible mechanical components. With advanced manufacturing techniques, precise tolerances can be achieved to prevent binding or excessive play, thus ensuring consistent performance throughout the product's lifecycle.

Magnetic assistance has become a widely adopted addition to conventional hinge mechanisms. Low-profile magnetic elements improve closure security and lessen mechanical stress on pivot points. Users enjoy seamless opening actions and gratifying closure responses, resulting in an interaction quality that competes with that of luxury accessories.

The ability to assemble flat-pack items has affected hinge design, steering it toward modular construction techniques. Components that are designed for efficient shipping and simplified manufacturing help lower production costs and provide customization options. Consumers can select from various finish combinations without requiring entirely separate product lines, streamlining inventory management for retailers.

Durability & Technical Finishes

Modern wallet hardware hinges must withstand thousands of opening and closing cycles while maintaining smooth operation and visual appeal. Advanced stress testing protocols now simulate years of daily use within accelerated laboratory conditions, ensuring components meet rigorous durability standards before reaching market. Fatigue resistance has become a primary design consideration, with engineers optimizing pivot geometries to distribute mechanical stress evenly across contact surfaces.

Technical finishing processes have evolved beyond traditional electroplating to include ceramic coatings, physical vapor deposition, and nano-scale surface treatments. These advanced finishes provide superior scratch resistance while offering unique aesthetic properties impossible to achieve through conventional methods. Brush antique brass and light gold finishes now incorporate protective layers that maintain their appearance despite frequent handling and environmental exposure.

The capacity to withstand erosion is a key execution degree for wallet equipment parts that come into contact with skin and are subjected to distinctive mugginess conditions. Cutting edge wrapping up frameworks build up boundary layers that halt oxidation whereas encouraging simple cleaning and upkeep. Users can confidently carry wallets in diverse climates without concern for hardware degradation or discoloration.

By utilizing exact fabricating resiliences , we can ensure that generation clusters will perform reliably. Computer-controlled machining forms guarantee dimensional precision inside micrometers, expelling inconstancy that seem affect pivot operation or life span. Quality affirmation conventions comprise of testing person components and utilizing arbitrary testing strategies to affirm compliance with details.

Antimicrobial surface treatments have gained prominence following increased awareness of hygiene concerns. Special coatings inhibit bacterial growth on frequently touched surfaces while maintaining the tactile qualities users expect from premium hardware components. These treatments integrate seamlessly with existing finish systems without affecting appearance or functionality.

Wallet Hardware Hinge Supplier: Carol

When it comes to putting these cutting-edge developments into practice in the production of wallet hardware hinges, a high level of manufacturing proficiency is indispensable. Carol serves as a complete solution for brands in search of premium metal frames and hardware accessories that feature cutting-edge design innovations. With extensive experience in producing handbag frames, metal purse frames, evening bag frames, and associated hardware components, Carol maintains the technical capabilities necessary for modern wallet accessory manufacturing.

The company's coordinates approach incorporates in-house electroplating offices, empowering total control over surface wrapping up forms from introductory plan through last bundling. This vertical integration guarantees steady quality whereas giving adaptability for custom determinations and fast model improvement. Natural obligation remains a center operational rule, with eco-friendly materials and forms coordinates all through the generation cycle.

Rectangular metal wallet frames exemplify the attention to detail that defines professional hardware manufacturing. These components have integral U-shaped bending designs that securely clamp onto wallet bodies while also serving as unique visual features. Permanent attachment between fabric and metal components is ensured through advanced bonding techniques such as precision-designed glue grooves and thermal pressure application. Layers of hot melt glue improve overall integrity while preserving the polished look that consumers associate with high-end accessories.

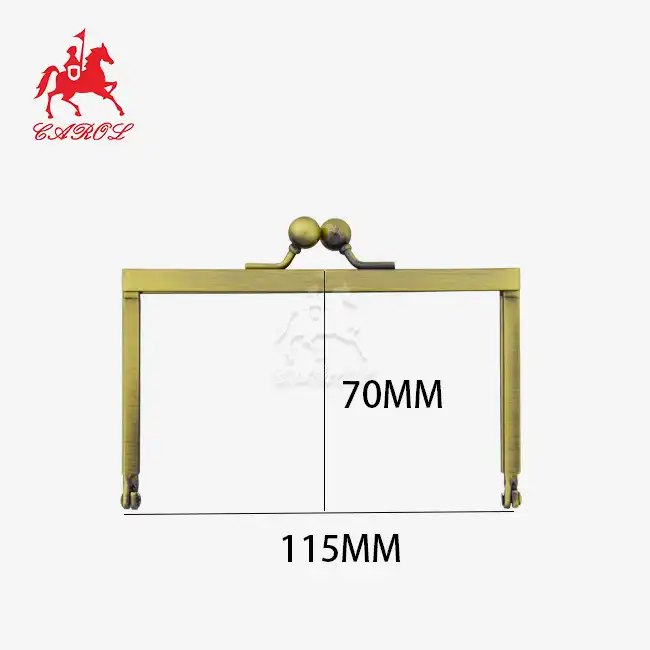

The capacity to customize amplifies to details of estimate, color, and fabric, empowering brands to make particular item offerings that compare with their stylish vision and the inclinations of their target showcase. Standard dimensions of 11.5cm by 7cm represent starting points for development rather than limitations, with modification possibilities accommodating diverse design requirements. Brush antique brass and light gold finishing options provide immediate availability while custom treatments remain accessible for specialized applications.

For inquiries regarding wallet hardware hinge solutions and custom manufacturing services, professional consultation is available through tony@carolxiao.com. The combination of traditional craftsmanship with modern manufacturing capabilities positions Carol as a reliable partner for brands seeking to implement the latest trends in wallet hardware design while maintaining the quality standards essential for competitive success in today's demanding marketplace.

_1753256285958.png)

_1754990596544.webp)