General Load Range by Scenario

The load capacity of zinc die-cast hooks can vary significantly depending on their intended use and design. In general, these hooks are engineered to withstand considerable weight, making them suitable for a wide range of applications in the bag and accessories industry.

For everyday handbags and purses, zinc die-cast hooks are typically designed to support loads ranging from 5 to 15 kilograms (11 to 33 pounds). This capacity is more than sufficient for most scenarios, considering that the average handbag rarely exceeds 2-3 kilograms in weight, even when fully loaded with personal items.

In the case of larger bags, such as weekender bags or small luggage pieces, zinc die-cast hooks may be engineered to handle loads of up to 20-30 kilograms (44-66 pounds). These heavier-duty hooks are often used for shoulder straps or as attachment points for removable straps, ensuring that they can withstand the stress of carrying more substantial weights.

For specialized applications, such as industrial or outdoor gear, zinc alloy die casting doghooks can be designed to support even greater loads. Some high-performance hooks can handle weights exceeding 50 kilograms (110 pounds), though these are not typically found in everyday fashion accessories.

Key Influencing Factors

Several factors contribute to the load capacity of zinc die-cast hooks. Understanding these elements is crucial for manufacturers and designers when selecting the appropriate hardware for their products:

1. Alloy Composition: The specific zinc alloy used in the die-casting process plays a significant role in determining the hook's strength. Alloys with higher percentages of aluminum and copper tend to offer increased strength and durability.

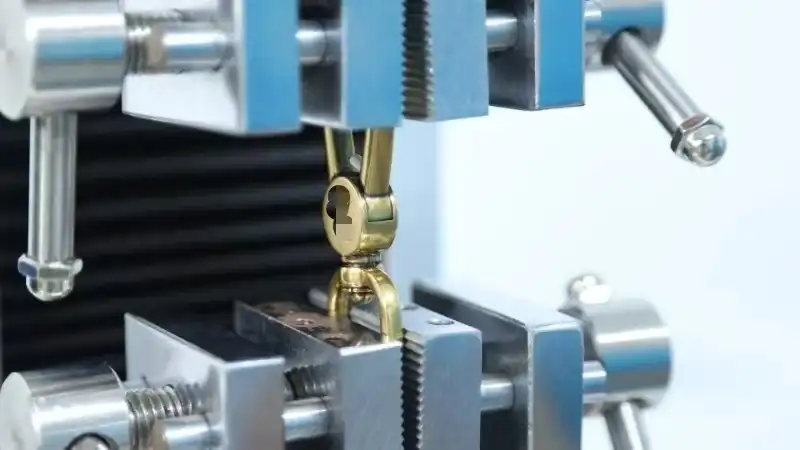

2. Design and Thickness: The shape and thickness of the hook greatly influence its load-bearing capacity. Hooks with reinforced stress points and thicker cross-sections generally have higher load capacities.

3. Manufacturing Process: The quality of the die-casting process, including factors such as temperature control and cooling rates, can affect the structural integrity of the final product.

4. Surface Treatment: Finishing processes like e-coating can enhance the hook's resistance to wear and corrosion, indirectly contributing to its long-term load-bearing ability.

5. Attachment Method: The way the hook is attached to the bag or strap (e.g., riveted, sewn, or welded) can impact its effective load capacity.

For instance, consider a Factory Customized 40MM Zinc Alloy Die Casting Doghook Rectangle Ring. With dimensions of 68mm x 40mm and weighing 26.6 grams, this hook exemplifies how design choices influence load capacity. Its rectangular shape provides excellent structural integrity, while the e-coating finish (available in gunmetal or coffee) adds durability and aesthetic appeal.

Important Note

While zinc die-cast hooks are known for their strength, it's crucial to note that the stated load capacity should be considered a guideline rather than an absolute limit. Factors such as repeated stress, environmental conditions, and unexpected impacts can affect a hook's performance over time.

When choosing hardware for their products, designers and manufacturers should constantly consider safety. To do this, hooks must be used whose load capabilities are far higher than the expected weight they would support. Generally speaking, a safety ratio of at least 2:1 is used, meaning the hook should be able to support at least twice the highest anticipated weight.

It's crucial to take into account the potential dynamic loads that a hook may encounter. For instance, the instantaneous pressures produced by a handbag swinging while being carried may be more than the static weight of the bag and its contents. Hooks used in these kinds of applications should thus be made to resist these dynamic loads.

Regular inspection and maintenance of zinc die-cast hooks are recommended, especially for items that are subjected to heavy use or challenging environments. This can help identify any signs of wear or damage before they lead to failure.

Zinc Alloy Die Casting Doghook Supplier: Carol

When it comes to sourcing high-quality zinc alloy die casting doghooks for your handbag, evening bag, or accessory manufacturing needs, Carol stands out as a reliable partner. With years of experience in producing hardware accessories and metal frames for the fashion industry, Carol offers a wide range of products that combine durability with aesthetic appeal.

Their Factory Customized 40MM Zinc Alloy Die Casting Doghook Rectangle Ring is just one example of their commitment to quality and versatility. Available in various finishes such as E-Coating Gunmetal and E-Coating Coffee, these hooks are suitable for a wide range of applications, including straps, bags, belting, leathercraft, key chains, and ID card hooks.

Carol's advantages extend beyond just product quality. From design to manufacturing, plating, and packing, they provide a full range of services from their own electroplating plant. In addition to offering more customization choices to satisfy your unique needs, this vertical integration guarantees constant quality.

For those seeking a reliable supplier of zinc alloy die casting doghooks and other hardware accessories, Carol offers the expertise and flexibility needed in today's competitive market. To explore how Carol can support your manufacturing needs, reach out to their team at tony@carolxiao.com. Whether you're looking for standard products or custom solutions, Carol is equipped to deliver hardware that meets your exact specifications in terms of size, color, and material.

_1753256285958.png)

_1754990596544.webp)