We'll examine several methods and provide professional advice as we dig into the nuances of installing metal internal flex frames for handbags in this extensive tutorial. From the precision required for the screw-on method to the dexterity required for the glue-on approach, we'll handle everything to ensure your handbag frame installation is perfect. So grab your materials and let's begin creating purses that are sturdy, elegant, and long-lasting.

Screw-On Type

The screw-on method for installing metal internal flex frames is a time-honored technique favored by many purse makers for its reliability and strength. This approach involves securing the frame to the fabric using small screws, creating a robust connection that can withstand the rigors of daily use.

Carefully line up the top edge of your handbag fabric with the metal internal flex frame to start the screw-on installation process. This is a critical condition where any misalignment might lead to an uneven or asymmetrical aperture. After you've found the ideal location, mark the screw holes on the cloth using fabric chalk or a washable marker.

The next step is to make tiny, reinforced holes in the cloth where the screws will go. To guarantee lifespan and avoid ripping, this step is essential. At each indicated screw position, cut little rings of leather or strong interfacing and attach them to the wrong side of the cloth. Over time, these reinforcements will lessen wear and tear by more uniformly distributing the pressure from the screws.

It's time to secure the frame after putting your reinforcements together. Make small pilot holes in the reinforcements and fabric first, using an awl or a thin nail. This will not only reduce the likelihood of cloth ripping but also facilitate the insertion of screws. Place the frame carefully, then drive the screws into the pilot holes in the cloth and through the holes in the frame. Take care not to overtighten and ruin the cloth by using a little screwdriver to tighten each screw.

Make sure the cloth is uniformly dispersed and smooth as you proceed around the frame. Before moving on, gently correct the material if you see any puckering or unevenness. Carefully pull the frame to ensure that it is firmly attached once all the screws have been inserted and fastened to the metal internal flex frame purse.

The screw-on method offers several advantages for metal internal flex frame installation. It provides a very secure attachment that can handle the weight of heavier purse contents. Additionally, this method allows for easier frame replacement if needed in the future, as the screws can be removed without damaging the fabric.

Glue-On Type

While the screw-on method has its merits, the glue-on technique for installing metal internal flex frames offers a sleek, seamless finish that many purse makers prefer. This method is particularly well-suited for delicate fabrics or designs where visible hardware might detract from the overall aesthetic.

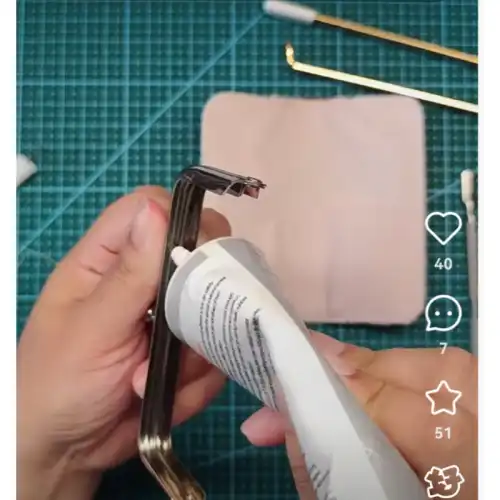

The first step in the glue-on procedure is to choose the right adhesive. Choose a flexible, durable adhesive made especially for joining cloth to metal. Crafters and expert handbag makers alike often use E6000 and Aleene's Fabric Fusion. The dynamic movement of a handbag frame depends on these adhesives' ability to form a strong bond while maintaining some flexibility.

It is important to prepare the cloth and the frame before using any glue. Rubbing alcohol should be used to completely clean the metal internal flex frame to get rid of any dirt or oils that might impede the bonding process. Likewise, make sure the cloth is clean and devoid of fluff or loose threads.

When it is time to install the frame, labor in small increments to guarantee precision. The textile will be in contact with the frame's channel, which should be coated with a thin, uniform layer of adhesive. It is crucial to apply a moderate quantity in order to prevent the adhesive from seeping out and the textile from discoloring. A bone folder or other flat instrument should be used to firmly press the cloth into the frame's bonded channel in order to ensure complete contact and eliminate any air pockets.

To avoid puckering or wrinkles, keep the cloth under constant tension as you go around the frame. Using tiny binder clips to keep pieces in place while the glue cures could be useful if you're dealing with a very fragile or slick cloth. To avoid any stains or indentations, be sure you sandwich a piece of waste fabric between the clip and the fabric of your purse.

Achieving a neat, polished edge where the cloth meets the frame is one of the difficulties with the glue-on technique. Some handbag makers decide to deal with such an issue by folding a small hem before gluing to provide a neat finish. Alternatively, trim the excess fabric along the frame when the glue has dried, and apply a fabric sealer to prevent fraying at the edge of the metal internal flex frame purse.

The glue-on technique for installing metal internal flex frames requires patience and a steady hand, but the results can be stunning. This method creates a smooth, uninterrupted line along the purse opening, ideal for sleek, modern designs or when working with luxurious fabrics where you want to minimize visible hardware.

Finishing And Inspection

After successfully installing your metal internal flex frame using either the screw-on or glue-on method, it's crucial to focus on the finishing touches and conduct a thorough inspection. This final stage ensures that your purse not only looks professional but also functions flawlessly.

Start by closely inspecting the frame installation over its whole length. Look for any places on the cloth where glue could have gotten on it or where it might not be firmly affixed. Make sure all of the screws are securely fastened and that none are sticking out or catching on the fabric if you've used the screw-on approach. For glue-on installs, gently press along the frame to confirm the connection. It could be necessary to reapply glue in any weak regions you find.

Next, focus on the cloth surrounding the frame. Be careful not to cut too close to the glue line or seam when trimming any excess fabric or threads. One way to prevent unraveling of a frayed cloth is to apply a little amount of fray check or clear nail polish to the cut edges.

The functionality of the frame is just as important as its appearance. Open and close the frame multiple times to ensure smooth operation. If you encounter any sticking points or resistance, investigate the cause. It could be excess fabric caught in the mechanism or a misaligned component that needs adjustment.

For purses with a lining, this is the time to attach it, carefully concealing any raw edges or hardware. Pay special attention to how the lining interacts with the frame, ensuring it doesn't interfere with the opening and closing mechanism of the metal internal flex frame purse.

Give your handbag a last pressing if you're happy with the frame installation and general design. Choose the appropriate heat setting for your fabric, and use a press cloth to smooth out any creases or wrinkles that may have formed during construction. The general appearance of your finished product might be much improved by this stage.

Lastly, consider adding any final embellishments or hardware, such as feet, clasps, or decorative elements. These finishing touches can elevate your purse from homemade to haute couture.

Metal Internal Flex Frame Purse Supplier: Carol

Crafting the perfect purse requires not just skill and creativity, but also high-quality materials. When it comes to metal internal flex frames, Carol stands out as a premier supplier in the industry. With years of experience in producing hardware accessories and metal frames for handbags, leather goods, and luggage, Carol has established itself as a go-to source for manufacturers and designers alike.

Carol's metal internal flex frames may be customized to fit your specific needs and come in a large range of sizes, colors, and materials. The exceptional longevity, aesthetic appeal, and environmentally safe materials utilized in their products demonstrate their dedication to excellence. The ideal starting point for your designs is Carol's frames, whether you're making sophisticated evening bags or practical daily purses.

Their all-inclusive service, which includes order fulfillment, design consulting, and post-purchase assistance, is what distinguishes Carol. Their on-site electroplating plant guarantees a smooth production process with reliable quality and prompt outcomes. Working with Carol might be the game-changer you've been waiting for if you want to improve your purse-making efforts or optimize your production process.

Ready to take your purse designs to the next level? Reach out to Carol today at tony@carolxiao.com to explore their range of metal internal flex frame purses and discover how they can support your creative vision. With Carol's expertise and quality products, your next purse project is bound to be a resounding success.

_1753256285958.png)

_1754990596544.webp)