What materials are handbag frames made of?

The material used to make the handbag frames is very important since it affects the product's appearance, cost, durability, and functionality. Carol looks at 5 types of frame materials: iron, copper, stainless steel, zinc alloy, and aluminium. Carol also provides custom solutions to clients.

Fundamental Materials: Iron and Copper in Mass Production

In the realm of mass-produced handbags, two materials stand out for their widespread adoption due to their balance of cost-effectiveness and functional performance: iron and copper. These materials form the foundation of the handbag frame industry, catering to the demands of large-scale manufacturing while meeting basic structural needs.

Iron: The Economical Workhorse of Handbag Frames

Iron ranks as the most commonly used material for handbag frames, particularly in budget-friendly and mid-range handbag lines. The main reason it is so popular is that it is cheap, which makes it perfect for high-volume production where keeping costs down is very important. Iron is strong enough to handle the normal forces of opening and closing a handbag, so it supports the bag's opening without bending too much.

From a manufacturing perspective, iron offers favorable workability. It can be easily shaped through processes such as bending, stamping, and welding, allowing manufacturers to produce frames in various sizes and basic designs to accommodate different handbag styles. Additionally, iron's availability in abundant quantities ensures a stable supply chain, reducing production delays and cost fluctuations. However, iron is prone to corrosion when exposed to moisture and oxygen over time. This limitation is mitigated by the fact that handbag frames are typically covered by fabric, leather, or other decorative materials, which act as a barrier against environmental factors. In some cases, iron frames may also undergo basic surface treatments, such as painting or plating with a thin layer of protective metal, to enhance their resistance to rust.

Copper: Balancing Malleability and Aesthetic Appeal

Copper emerges as the second most widely used material for handbag frames, positioned between iron and more premium options in terms of cost and performance. Copper is very malleable, which means that it can be sculpted into complex shapes with considerable ease. Copper is a fantastic choice for purses that need frames with decorative characteristics like curved edges, embossed patterns, or delicate hinges since it is strong and durable.

Copper is beautiful on its own. Copper naturally develops a patina over time. This is a greenish layer that forms when the metal oxidizes. Many people like it because it looks old. Copper frames are a popular choice for designs that want to give off a sense of timelessness since the patina adds character to the bags. In terms of mechanical properties, copper provides adequate strength for most handbag applications, though it is slightly softer than iron. Its conductivity is not a significant factor in handbag frame functionality, but its resistance to corrosion is superior to that of iron, reducing the need for extensive protective coatings. Copper frames are commonly found in mid-to-high-end handbags where both performance and visual appeal are prioritized.

Specialized Materials: Stainless Steel, Zinc Alloy, and Aluminum

While iron and copper dominate mass production, certain handbag designs demand materials with enhanced properties or unique aesthetic qualities. Stainless steel,zinc alloy and aluminum cater to these specialized needs, offering solutions for high-end durability and vintage-inspired aesthetic, respectively.

Stainless Steel: Durability for High-End Requirements

Stainless steel represents the premium choice forhigh-end handbag frames,, selected primarily for its exceptional durability and resistance to corrosion. Composed of iron alloyed with chromium (and often other elements like nickel or molybdenum), stainless steel forms a passive oxide layer on its surface that prevents rust and degradation, even when exposed to moisture, sweat, or environmental pollutants, which makes it an ideal material for high-end handbags designed to withstand long-term use and maintain their structural integrity over time.

In addition to its corrosion resistance, stainless steel boasts high tensile strength and hardness, ensuring that the frame retains its shape under repeated stress. These mechanical properties make it suitable for handbags with larger dimensions or those intended to carry heavier loads. However, these advantages come with trade-offs. Stainless steel is more expensive than iron or copper, both in terms of raw material costs and manufacturing expenses. Because it is so hard, it is harder to shape and needs special tools and more complicated processing methods. This means that it can only be used in high-end items when the extra expense is worth it because of the material's performance benefits. Many high-end handbag lines, professional accessories, and designs that need to last a long time and be easy to care for use stainless steel frames.

Zinc Alloy: Nostalgic Charm for Vintage-Inspired Designs

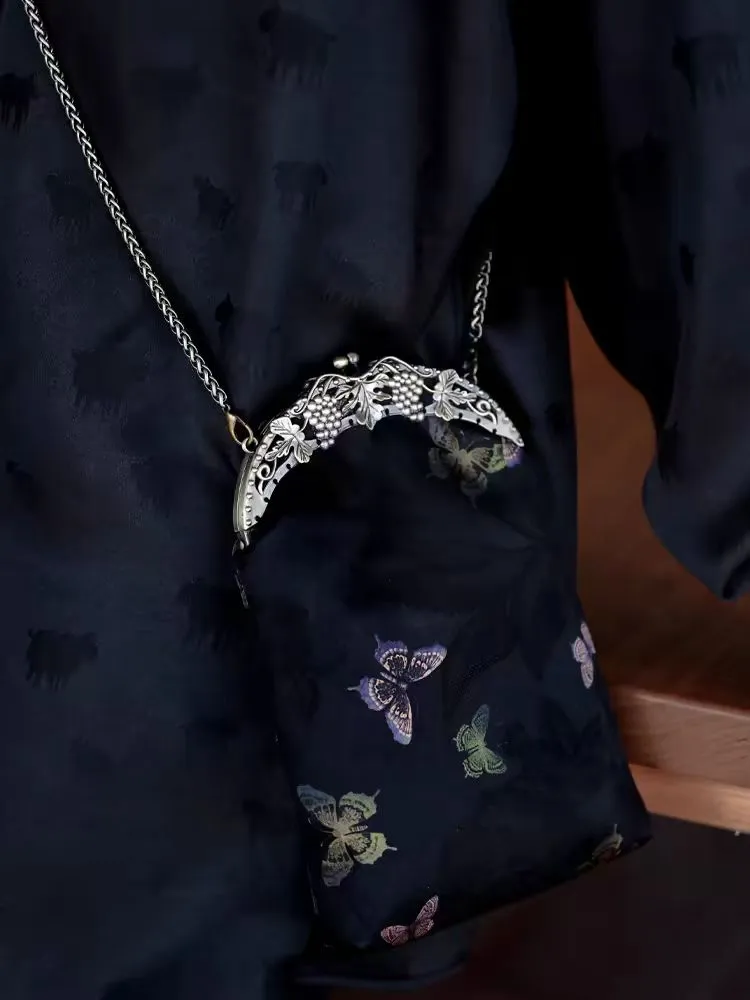

Zinc alloy has carved out a niche in the handbag frame market, primarily valued for its ability to replicate the look and feel of vintage accessories. Zinc alloys are made by mixing zinc with metals like aluminum, copper, or magnesium. They are great for casting because they let producers make very precise and complicated frame designs. This makes them great for vintage-style purses with fancy patterns, filigree work, or designs from the past.

The casting process for zinc alloys enables the creation of complex shapes with tight tolerances, capturing fine details that would be difficult or costly to achieve with other materials. Additionally, zinc alloys can be easily plated with metals like brass or nickel to enhance their appearance and mimic the look of more expensive materials used in traditional handbag craftsmanship. While zinc alloys provide adequate strength for their intended applications, they are generally softer than iron or stainless steel, making them more susceptible to deformation under excessive force. This limitation restricts their use to handbags with lighter loads and less rigorous usage scenarios. The relatively low melting point of zinc alloys simplifies the manufacturing process compared to stainless steel, though their cost is typically higher than iron due to the alloying elements and finishing treatments involved. For designers seeking to evoke a sense of nostalgia or historical elegance, zinc alloy frames offer a practical and visually appealing solution.

Aluminum: Lightweight Potential with Limited Adoption

Aluminum stands out among handbag frame materials for its exceptional lightweight properties, a characteristic that would seem advantageous for accessories where portability is valued. Aluminum has a significantly lower density than iron, copper, or stainless steel, which could reduce the overall weight of the handbag, enhancing user comfort during extended carrying. However, despite this benefit, aluminum sees limited adoption in handbag frame production.

Customised According To Clients' Requirements

In the competitive handbag market, where brand identity and unique design are key differentiators, the ability to customise handbag frame materials according to clients' specific requirements is essential. Manufacturers like Shenzhen Carol Metal that offer customisation services can cater to the diverse needs of designers, brands, and retailers, providing tailored solutions that align with their creative vision, functional needs, and target market preferences.

Material selection customisation is a fundamental aspect of meeting client requirements. Depending on the project's specifications, clients may opt for aluminium, zinc alloy, iron, copper, and stainless steel to achieve the desired balance of properties. For instance, a client designing a lightweight, everyday handbag may prioritize aluminium for its low weight, while budget-sensitive brands producing mass-market accessories often choose iron for its cost-effectiveness and reliable structural support. Mid-range designers seeking a blend of malleability and vintage charm might select copper, which develops a distinctive patina over time and allows for subtle decorative detailing. A luxury brand creating a statement evening bag may choose a zinc alloy for its ability to support intricate plating and ornate designs, while high-end labels focused on long-term durability often opt for stainless steel, valued for its corrosion resistance and ability to maintain shape through heavy use. Shenzhen Carol Metal works closely with clients to assess their needs, including factors such as intended use, desired aesthetics, budget constraints, and performance expectations, to recommend the most suitable material or material combination from this diverse range.

Customisation extends beyond material selection to include dimensions and shape. Clients often require handbag frames in specific sizes to fit unique bag designs, whether it's a small clutch frame or a large tote bag frame. Shenzhen Carol Metal utilises advanced manufacturing techniques, such as CNC machining and precision casting, to produce frames with exact dimensions, ensuring a perfect fit with the bag's structure. Additionally, clients can request custom shapes, from curved edges and angular lines to asymmetrical designs, enabling the creation of truly one-of-a-kind handbags that stand out in the market.

Choose Shenzhen Carol Metal

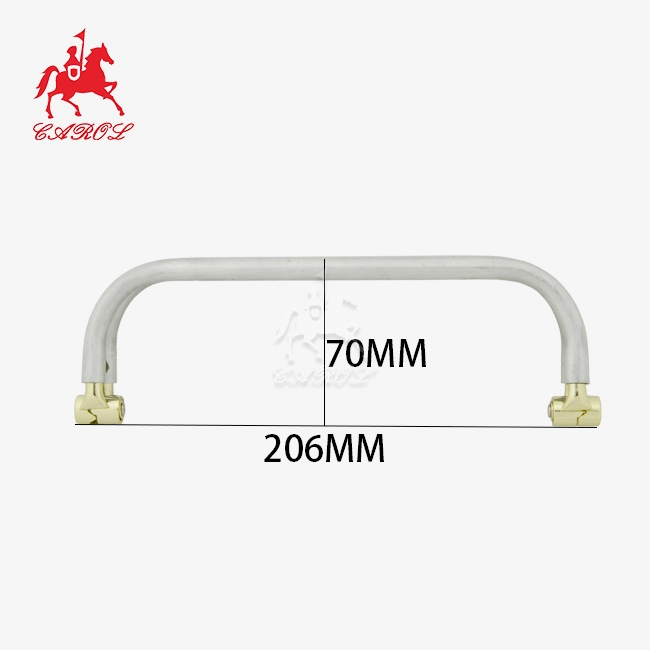

Whether you're crafting a sleek doctor bag, a charming purse, or unique accessories, Shenzhen Carol Metal's aluminium tubular internal hinge doctor handbag frame, measuring 20.6 cm x 7 cm with a stunning NF nickel finish, serves as the perfect foundation. Made from premium aluminium and zinc alloy, it blends durability with style, and we're ready to customise it to your exact needs: adjust sizes, choose from a range of colours, or select alternative materials to match your vision.

Reach out today to discuss your project, request samples, or start planning your custom order. Drop us an email at tony@carolxiao.com or developmente@carolxiao.com.

References

· ASM International. (2019). ASM Handbook: Properties and Selection of Nonferrous Alloys and Special-Purpose Materials. ASM International.

· Budinski, K. G., & Budinski, M. K. (2010). Engineering Materials: Properties and Selection (9th ed.). Prentice Hall.

· European Chemicals Agency. (2023). REACH Regulation (EC) No 1907/2006.

· International Zinc Association. (2021). Zinc Alloys in Design and Manufacturing.

· RoHS Directive. (2011). Directive 2011/65/EU of the European Parliament and of the Council. Official Journal of the European Union.

_1753256285958.png)

_1754990596544.webp)