Custom Metal Bag Frame Process

Making custom metal bag frames takes a number of steps that are all linked together and require technical knowledge, attention to detail, and a focus on meeting the demands of the user. These steps include figuring out the right forms and closure mechanisms and making sure the frames are the right size.

Design and Specification for Custom Metal Bag Frames

The foundation of any custom metal bag frame lies in meticulous design and specification planning, where the unique requirements of the bag, whether functional, stylistic, or contextual, are translated into tangible parameters. This phase begins with understanding the intended use of the bag, as this directly influences critical design elements such as shape, closure method, and dimensions.

Shape selection is a primary consideration, with four main types dominating the market: rectangles, open channels, curves, and circles. People like rectangular metal bag frames because they are quite strong, which makes them perfect for structured bags that need to have a certain shape, like briefcases or formal purses. Open channels, currently the most popular shape, offer a balance of flexibility and support, featuring a partially enclosed design that allows for easier integration with bag materials like leather or fabric; this versatility makes them suitable for a wide range of styles, from casual tote bags to semi-formal purses. Curved and circular frames, by contrast, cater to more decorative or specialized designs, adding softness or a unique visual focal point. Curved frames are often used in vintage-inspired bags, while circular frames may adorn small clutches or novelty bags.

Closure methods are another pivotal aspect of design, with over 20 types available to suit different functional and aesthetic needs. These methods fall into two primary categories: kiss lock closures and buckle closures. Kiss lock closures, characterized by interlocking elements, include variations such as double balls, cross balls, teardrops, and hammers; their smooth, seamless operation and decorative potential make them popular for elegant or retro-style bags. Buckle closures, which use mechanical fastening, come in shapes including squares, single balls, cylinders, and trapezoids. They are more secure and last longer. These are often preferred for bags intended for heavy use or outdoor settings.

Dimension specifications are equally critical, with widths ranging from 3 to 12 inches to accommodate diverse bag sizes and purposes. Smaller frames (3–5 inches) are typically used for compact accessories like coin purses, evening clutches, or cosmetic bags, where portability is key. Medium frames (6–8 inches) find application in everyday handbags, balancing capacity with manageability. Larger frames (9–12 inches) are reserved for bags requiring more storage, such as tote bags, travel pouches, or laptop sleeves, where structural support for heavier loads is necessary. Each dimension range of the metal bag frame is selected based on the bag’s intended contents, user demographics, and style goals, ensuring the frame complements rather than constrains the bag's functionality.

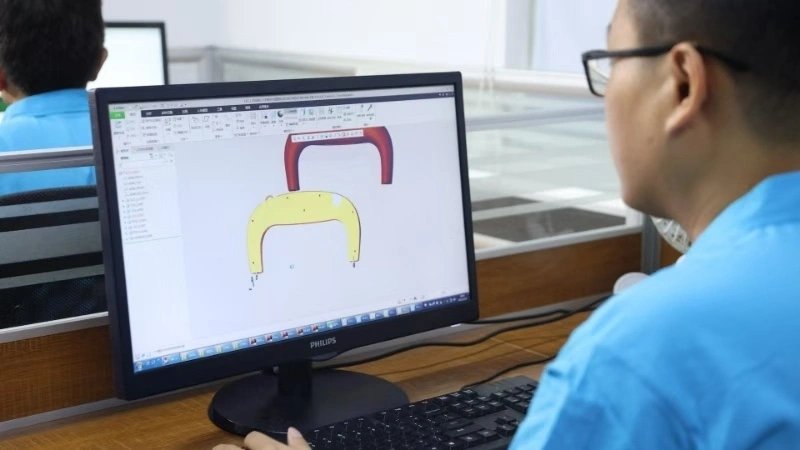

By the end of the design phase, all specifications, shape, closure, and dimensions are consolidated into detailed technical drawings, serving as a blueprint for the manufacturing process. This stage also involves material selection, preliminary assessments, considering factors like metal type (e.g., brass, steel, aluminum) based on durability, cost, and aesthetic properties, which further refines the design for production feasibility.

With design and specifications finalized, the process transitions from conceptual planning to the hands-on work of manufacturing, where these blueprints are transformed into physical frames through precise fabrication techniques.

Manufacturing Techniques and Material Execution in Custom Metal Bag Frame Production

The manufacturing phase of custom metal bag frames is where design specifications are brought to life, requiring a combination of advanced machinery and skilled craftsmanship to ensure precision and consistency. This phase begins with material preparation, where the chosen metal, selected based on factors like strength, malleability, and corrosion resistance, is cut into raw blanks that match the required dimensions of the frame.

Cutting is typically executed using laser cutting or precision shearing equipment, which allows for high accuracy even with complex shapes. Laser cutting, in particular, is favored for its ability to create intricate edges and detailed patterns, making it suitable for frames with decorative elements or non-standard shapes like curves and circles. For simpler shapes such as rectangles, mechanical shearing may be used to streamline the process, ensuring clean, straight edges that facilitate subsequent manufacturing steps.

Following cutting, the metal blanks undergo forming processes to achieve the desired shape. This often involves bending, where hydraulic presses or specialized dies are used to shape the metal into rectangles, open channels, or curves. For circular frames, rolling machines may be employed to gradually bend the metal into a continuous loop, ensuring uniformity in diameter and curvature. The forming stage requires careful calibration to avoid over-bending or material fatigue, which could compromise the metal bag frame's structural integrity.

Once the basic shape is formed, attention turns to integrating the closure mechanisms. For kiss lock closures, this involves attaching interlocking components, such as balls or teardrops, to the frame ends using welding or riveting. Welding is preferred for its strength and seamless finish, though riveting may be used for materials that are difficult to weld or when a more decorative fastening is desired. Buckle closures, on the other hand, require precise drilling or punching to create holes or slots for the buckle components, followed by assembly to ensure smooth operation and a secure fit.

Surface treatment is the final step in manufacturing, aimed at enhancing both the appearance and durability of the metal bag frame. Common treatments include polishing, which creates a smooth, reflective finish; plating (with materials like nickel, gold, or chrome) to improve corrosion resistance and add color; or powder coating for a matte or textured surface. These treatments not only keep the metal from getting worn down or damaged by the environment, but they also let you customize the frame to match the bag's overall design, making sure it fits with the look you want.

After they are made, each frame must go through a strict testing process to make sure it fulfills the design and performance standards. This is the basis of quality assurance and application validation.

Quality Assurance, Testing, and Application Validation for Custom Metal Bag Frames

Quality assurance is an important step in the process of making custom metal bag frames. It makes sure that each product fulfills the requirements for practicality, durability, and visual consistency that were set before the work began. In this step, the frame is tested and inspected in a systematic way to find any flaws or differences from the design. This makes sure that it will work well in its intended use.

Dimensional accuracy is the first checkpoint, verified using precision measuring tools such as calipers, micrometers, and coordinate measuring machines (CMMs). These tools confirm that the metal bag frame's width, height, and curvature align with the specified tolerances, typically within ±0.1mm for critical dimensions. For example, a 6-inch frame intended for a medium handbag must measure exactly 6 inches to ensure proper fit with the bag's body, preventing issues like uneven material tension or misalignment with closure mechanisms.

Functional testing focuses on the closure mechanism, assessing its ability to operate smoothly and securely. For kiss lock closures, this involves repeated opening and closing (often 500+ cycles) to ensure the interlocking components do not wear prematurely or fail to engage properly. Force tests are used to test buckle closures for simplicity of use and strength. These tests imitate daily wear and make sure the buckle stays attached under normal loads. In addition to checking for structural stability, frames with open channels are also checked to make sure that the channel keeps its shape and doesn't change shape when pressure is applied. This is important for keeping the bag's structure over time.

Durability testing evaluates the metal bag frame's resistance to environmental factors and wear. Corrosion resistance is assessed through salt spray testing, where frames are exposed to a saline mist for extended periods to check for rust or plating degradation, especially important for frames intended for use in humid climates or with frequent contact with moisture. Impact testing may also be conducted, simulating accidental drops or bumps to ensure the frame does not crack or bend, preserving both functionality and appearance.

Application validation ties the quality assurance process to real-world use, ensuring the frame is suitable for its intended scenario. For instance, a 3-inch circular frame with a kiss lock closure, tested for durability and precision, is validated for use in an evening clutch, where its small size and decorative closure align with the bag's purpose. A 10-inch open channel frame, meanwhile, must pass structural tests to confirm it can support the weight of a tote bag filled with daily essentials, validating its use in casual settings.

By the conclusion of this phase, the custom metal bag frame is confirmed to meet all design, functional, and durability requirements, ready to be integrated into the final bag product. This rigorous process, from design planning to manufacturing and quality assurance, ensures that each frame not only enhances the bag’s structure but also contributes to its overall appeal and longevity.

Carol: Your Partner in Metal Bag Frame

With our own electroplating factory, Carol offers a comprehensive service from design conception to order processing, production, plating, and packaging. Whether you're looking for OEM/ODM brand processing or seeking a reliable partner for your bag hardware needs, Carol is equipped to meet and exceed your expectations.

From the various shapes and closure methods to the wide range of dimensions available, Carol Metal Products Co., Ltd. stands ready to bring your bag design visions to life.

Are you ready to elevate your bag designs with high-quality metal bag frames? Contact us today at tony@carolxiao.com to discuss your project needs or to request a custom quote.

References

- Smith, J. (2020). Metal Fabrication for Accessories: Precision Techniques in Frame Manufacturing. New York: Industrial Press.

- Jones, L. (2019). Bag Component Design: From Concept to Production. London: Fashion Technical Publications.

- American Society for Testing and Materials. (2021). ASTM F2853-11: Standard Specification for Metal Frames in Soft Goods. West Conshohocken: ASTM International.

- Brown, R. & Lee, K. (2022). Surface Treatments for Metal Accessories: Corrosion Resistance and Aesthetic Enhancement. Journal of Industrial Design, 15(3), 45-62.

_1753256285958.png)

_1754990596544.webp)