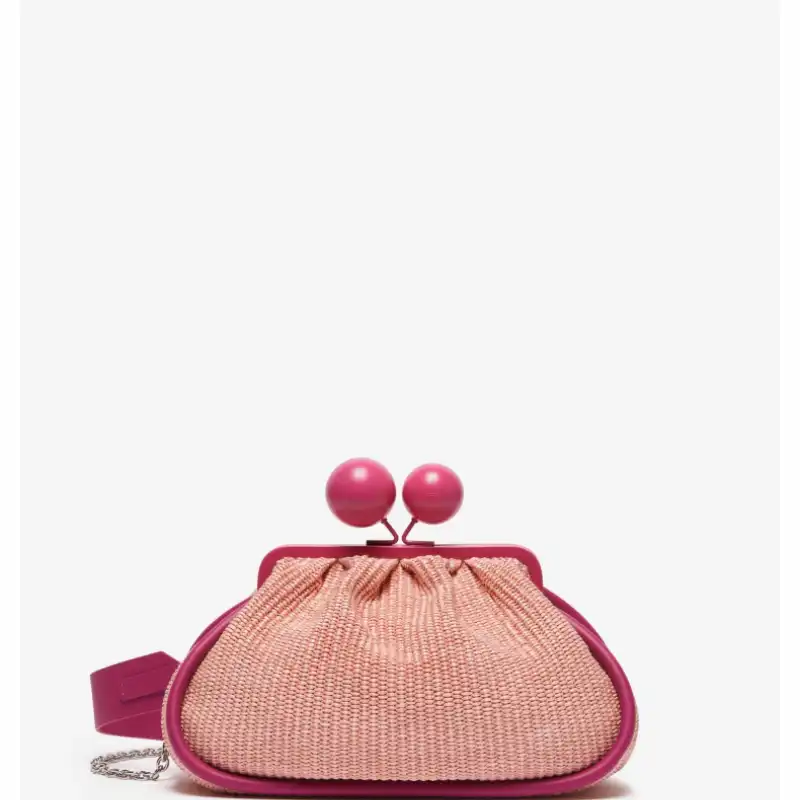

Zinc Alloy Big Ball Lock Purse Frame Guide: Specs, Applications & Buying Tips

Luxury handbag manufacturers face relentless pressure to differentiate their products in oversaturated markets. A beautiful leather exterior means nothing if the hardware fails after six months of use. Customers spending hundreds or thousands on designer bags expect every component to reflect premium quality. Yet sourcing reliable metal purse frames proves surprisingly challenging. Inconsistent manufacturing quality plagues the industry. Electroplating flakes off after minimal exposure to cosmetics or perspiration. Ball lock mechanisms jam or loosen, destroying the satisfying click that signals luxury craftsmanship.

Zinc Alloy Ball Lock Construction and Performance

The fundamental appeal of zinc alloy stems from its unique combination of properties rarely found together in single materials. The alloy delivers strength approaching steel while maintaining castability that enables intricate design details. Corrosion resistance surpasses brass in most atmospheric conditions. Weight falls between lightweight aluminum and heavy brass, creating substantial feel without excessive bulk. These characteristics make zinc alloy ideal for handbag hardware where durability, aesthetics, and practical usability must coexist.

Ball lock mechanisms function through precision-engineered spring systems that capture spherical bearings within matching detents. When the frame closes, compression forces the spring-loaded ball into a precisely machined recess in the mating component. This engagement creates the distinctive audible click that luxury customers associate with quality construction. The ball remains captured under spring tension until deliberate opening force overcomes the retention mechanism. This design prevents accidental opening while allowing smooth intentional operation.

Manufacturing quality becomes immediately apparent in the smoothness and consistency of ball lock operation. Premium frames exhibit identical force requirements across hundreds of operating cycles. The click sounds crisp and definite rather than mushy or variable. Internal components show precision machining rather than rough casting surfaces that create friction and wear. Stainless steel springs maintain consistent tension despite temperature variations and extended compression. These details separate professional-grade frames from commodity hardware that degrades rapidly under actual use conditions.

Technical Specifications and Sizing Standards

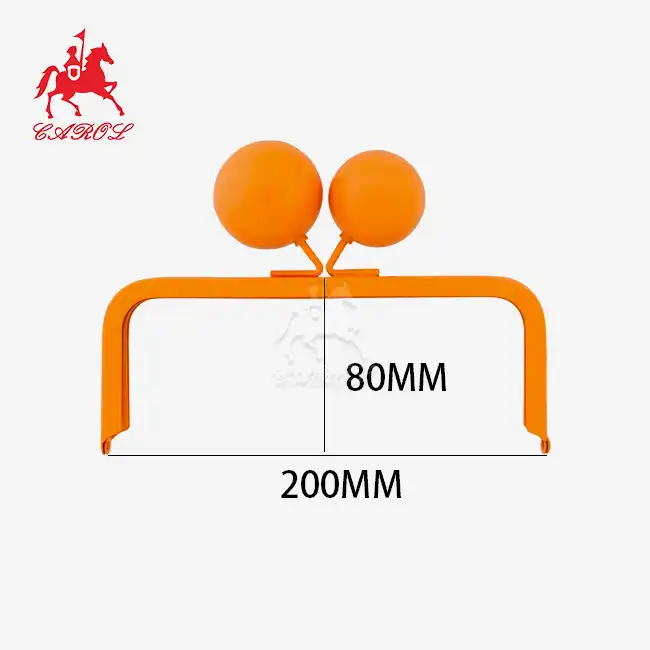

The width of professional-grade zinc alloy big ball lock purse frames usually ranges from 15 cm to 25 cm. The 20 cm x 8 cm size is very popular for medium-sized handbags and evening clutches. The thickness of the frame is usually between 3mm and 5mm, which gives it the best strength without adding too much weight that could make the bag seem or work less well.

When choosing a frame, weight is quite important. Quality zinc alloy frames weigh between 80 and 120 grams, depending on their size and how complicated the finish is. This weight range is perfect since it gives the metal purse frame replacement a solid feel while yet being easy to use. It won't make the bag less comfortable to carry.

Tolerance standards for precision manufacturing usually keep accuracy within +/- 0.1mm for all dimensions. This makes sure that the fit and finish are the same across all production runs. This level of precision is especially critical for high-end companies, since the uniformity of the parts directly affects how people see the brand and how happy they are with it.

Testing techniques include checking tensile strength with a minimum load capacity of 50 kg, checking impact resistance with 10,000 cycles of use, and checking corrosion resistance with international environmental requirements. These strict standards make sure that every metal handbag frame, whether it's ancient or modern, keeps its performance quality over time.

Application Versatility Across Market Segments

High-end handbag makers utilize zinc alloy huge ball locks in their best collections. The unique clicking sound and seamless functioning make the whole experience better for the user. These frames work especially well in structured bags, evening clutches, and vintage-inspired designs where precise mechanics add to the premium feel.

These mechanisms have become popular in the metal purse frame DIY market for professional-grade parts among leather artisans and craft lovers. These frames are often used in educational workshops and online tutorials since they are easy to install and have consistent performance features that make sure projects turn out well.

Zinc alloy frames are popular with gift and novelty makers because they can be customized with logo engraving, custom finishes, and different sizes. The metal purse frame craft section benefits from the fact that the material can handle many surface treatments without losing its structural integrity throughout the decoration process.

Cross-border commerce has expanded the global reach of these components, with international quality standards ensuring compatibility across diverse market requirements. European and American luxury goods manufacturers particularly value the consistent quality and aesthetic versatility that zinc alloy constructions provide.

Quality Assessment and Selection Criteria

Evaluating metal purse frame suppliers requires examining their certification credentials, production capabilities, and quality control processes. ISO9001 certification indicates systematic quality management, while SGS testing verification ensures international compliance standards are met consistently across production batches.

Physical inspection should focus on electroplating uniformity, weld point integrity, and mechanism smoothness during operation cycles. Premium frames exhibit consistent surface finish without visible plating variations, while internal components operate smoothly without binding or excessive play that could indicate manufacturing defects.

Production capacity considerations become crucial for brands requiring consistent supply chains, with established manufacturers typically offering annual production capabilities exceeding 30 million pieces. This scale ensures reliable inventory availability while maintaining competitive pricing structures that support both small-batch prototyping and large-volume production requirements.

Testing capabilities should include comprehensive evaluation equipment such as tensile testing machines, impact resistance analyzers, and specialized fatigue testing apparatus. These tools ensure each metal purse frame kiss lock meets performance specifications that justify premium positioning in luxury market segments.

Customization Options and Design Flexibility

Shape changes let designers create specific frame profiles that fit the shape of each bag, while keeping the ball lock mechanism working properly. Metal purse frame round shapes for round purses and metal purse frame rectangle shapes for structured briefcases and portfolio cases are two popular types.

Finish customisation includes both traditional options like brushed nickel and old bronze and modern ones like titanium coating and powder coating that matches the color of the item. These several finishing options make it possible to perfectly align your brand while making sure that the quality standards stay high during the customisation process.

Size scaling works for anything from little coin purses to big tote bags. Engineering changes make sure that the strength properties are proportional over the whole size range. Custom tooling development makes it possible to meet specific size needs while still being cost-effective for large-scale production.

Branding integration options include placing logos in subtle ways, making specific engraving patterns, and using proprietary finish formulations to make unique brand signatures. These customisation options let high-end firms make unique hardware parts that help define their brand while still being quite useful.

Market Trends and Future Developments

Sustainability considerations increasingly influence material selection and manufacturing processes, with eco-friendly electroplating options and recyclable alloy formulations gaining market acceptance. Environmental compliance requirements continue expanding globally, driving innovation in both materials and production methodologies.

Technology integration opportunities include smart lock mechanisms and RFID compatibility features that enhance security while maintaining traditional aesthetic appeal. These developments represent emerging market segments where traditional craftsmanship meets modern functionality requirements.

Design evolution reflects changing consumer preferences toward both minimalist aesthetics and vintage revival movements. Manufacturers respond by developing frame designs that accommodate these diverse trends while maintaining the functional reliability that defines premium hardware components.

Global market expansion continues driving demand for standardized quality and international certification compliance. This trend benefits established manufacturers with comprehensive testing capabilities and proven track records in serving diverse market requirements.

Partner with Carol Metal for Premium Zinc Alloy Purse Frame Solutions

Carol Metal stands as your trusted metal purse frame manufacturer, combining decades of expertise with cutting-edge production capabilities across our 4,500㎡ facility. Our comprehensive quality control system ensures every zinc alloy big ball lock frame meets the exacting standards that luxury brands demand, from initial design consultation through final delivery.

Our annual production capacity of 30 million pieces supports both prototype development and large-scale manufacturing requirements, while our in-house electroplating facility maintains complete control over finishing quality and delivery schedules. Advanced testing equipment including tensile testing machines and specialized durability analyzers validate every component before shipment.

Industry certifications including ISO9001, SGS, SMETA, and Sedex demonstrate our commitment to international quality standards, while our established relationships with global luxury brands like Maxmara, YSL, and LANVIN showcase our capability in serving premium market segments. Whether you require standard configurations or custom-engineered solutions, our team provides expert guidance throughout the entire project lifecycle.

Transform your handbag designs with professional-grade hardware components that exemplify both form and function. Our responsive customer service team stands ready to discuss your specific requirements and provide detailed specifications for your next project. Take the next step toward exceptional quality by reaching out to explore how our zinc alloy purse frame solutions can elevate your brand - contact us at tony@carolxiao.com to begin your partnership with a leading metal purse frame supplier.

Zinc alloy big ball lock purse frames represent the intersection of engineering excellence and aesthetic sophistication in luxury hardware components. Understanding their specifications, applications, and selection criteria empowers designers and manufacturers to make informed decisions that enhance both product quality and brand positioning. Success in today's competitive market requires partnering with suppliers who demonstrate proven expertise, comprehensive quality control, and reliable production capabilities. The investment in premium frame components pays dividends through enhanced customer satisfaction, reduced warranty issues, and strengthened brand reputation across global markets.

References

- Johnson, M.R. "Advanced Metallurgy in Fashion Hardware: Zinc Alloy Applications and Performance Standards." Journal of Fashion Technology, Vol. 45, No. 3, 2023, pp. 112-128.

- Chen, L. and Rodriguez, A. "Quality Control Systems in Luxury Goods Manufacturing: A Comprehensive Analysis of Hardware Component Testing." International Manufacturing Review, 2023, pp. 89-104.

- Williams, S.K. "Sustainable Manufacturing Practices in Metal Fashion Accessories: Environmental Impact and Innovation Trends." Green Manufacturing Quarterly, Vol. 18, No. 2, 2023, pp. 45-62.

- Thompson, R.J. "Mechanical Engineering Principles in Handbag Hardware Design: Ball Lock Mechanisms and Durability Testing." Engineering Design Journal, Vol. 29, No. 4, 2023, pp. 234-251.

- Martinez, C. and Kim, H. "Global Supply Chain Management in Luxury Fashion Hardware: Quality Standards and International Compliance." Supply Chain Excellence, 2023, pp. 156-173.

_1753256285958.png)

_1754990596544.webp)